Popular Woodworking 2002-06 № 128, страница 63

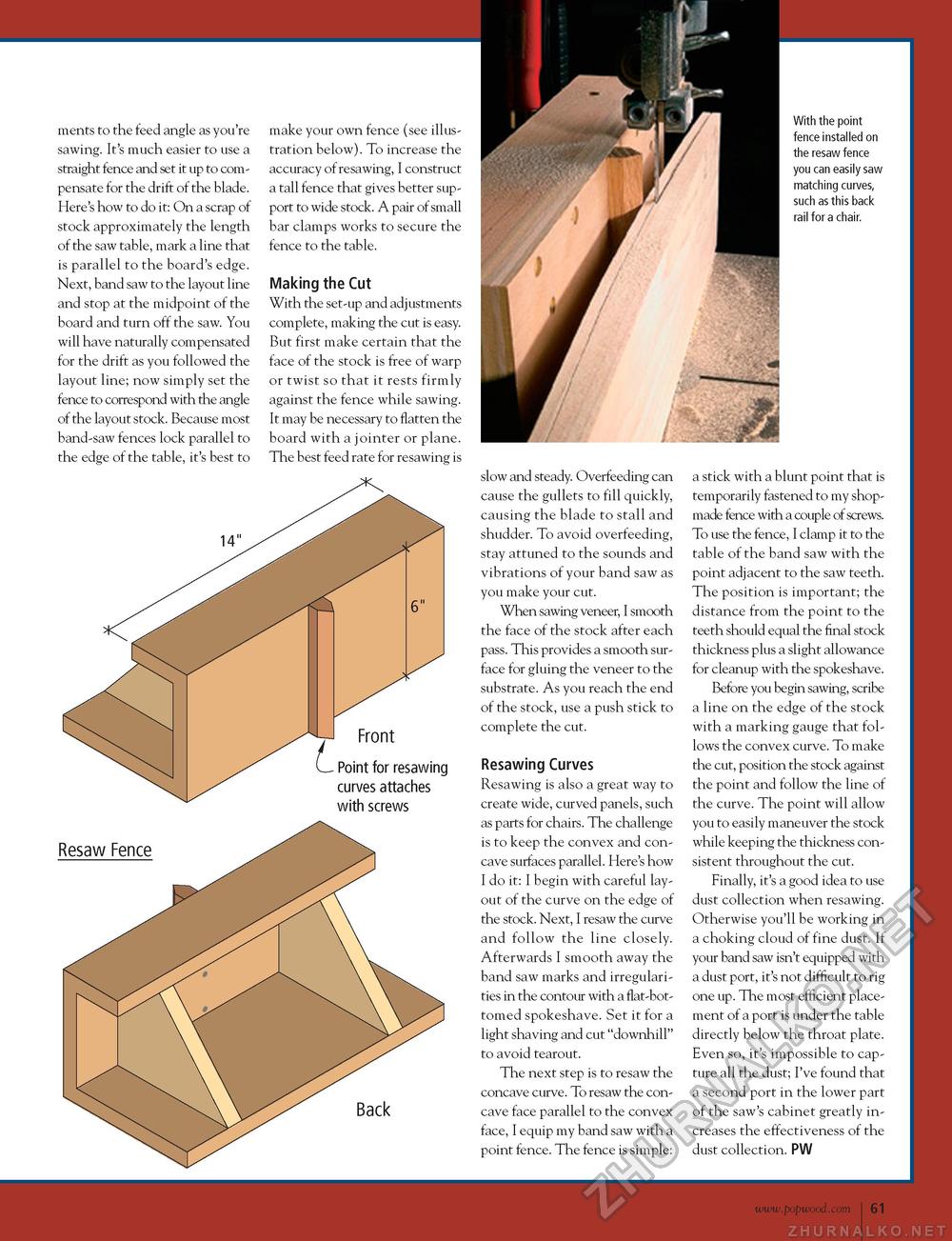

ments to the feed angle as you're sawing. It's much easier to use a straight fence and set it up to compensate for the drift of the blade. Here's how to do it: On a scrap of stock approximately the length of the saw table, mark a line that is parallel to the board's edge. Next, band saw to the layout line and stop at the midpoint of the board and turn off the saw. You will have naturally compensated for the drift as you followed the layout line; now simply set the fence to correspond with the angle of the layout stock. Because most band-saw fences lock parallel to the edge of the table, it's best to make your own fence (see illustration below). To increase the accuracy of resawing, I construct a tall fence that gives better support to wide stock. A pair of small bar clamps works to secure the fence to the table. Making the Cut With the set-up and adjustments complete, making the cut is easy. But first make certain that the face of the stock is free of warp or twist so that it rests firmly against the fence while sawing. It may be necessary to flatten the board with a jointer or plane. The best feed rate for resawing is slow and steady. Overfeeding can cause the gullets to fill quickly, causing the blade to stall and shudder. To avoid overfeeding, stay attuned to the sounds and vibrations of your band saw as you make your cut. When sawing veneer, I smooth the face of the stock after each pass. This provides a smooth surface for gluing the veneer to the substrate. As you reach the end of the stock, use a push stick to complete the cut. Resawing Curves Resawing is also a great way to create wide, curved panels, such as parts for chairs. The challenge is to keep the convex and concave surfaces parallel. Here's how I do it: I begin with careful layout of the curve on the edge of the stock. Next, I resaw the curve and follow the line closely. Afterwards I smooth away the band saw marks and irregularities in the contour with a flat-bottomed spokeshave. Set it for a light shaving and cut "downhill" to avoid tearout. The next step is to resaw the concave curve. To resaw the concave face parallel to the convex face, I equip my band saw with a point fence. The fence is simple: a stick with a blunt point that is temporarily fastened to my shop-made fence with a couple of screws. To use the fence, I clamp it to the table of the band saw with the point adjacent to the saw teeth. The position is important; the distance from the point to the teeth should equal the final stock thickness plus a slight allowance for cleanup with the spokeshave. Before you begin sawing, scribe a line on the edge of the stock with a marking gauge that follows the convex curve. To make the cut, position the stock against the point and follow the line of the curve. The point will allow you to easily maneuver the stock while keeping the thickness consistent throughout the cut. Finally, it's a good idea to use dust collection when resawing. Otherwise you'll be working in a choking cloud of fine dust. If your band saw isn't equipped with a dust port, it's not difficult to rig one up. The most efficient placement of a port is under the table directly below the throat plate. Even so, it's impossible to capture all the dust; I've found that a second port in the lower part of the saw's cabinet greatly increases the effectiveness of the dust collection. PW With the point fence installed on the resaw fence you can easily saw matching curves, such as this back rail for a chair. |