Popular Woodworking 2002-10 № 130, страница 37

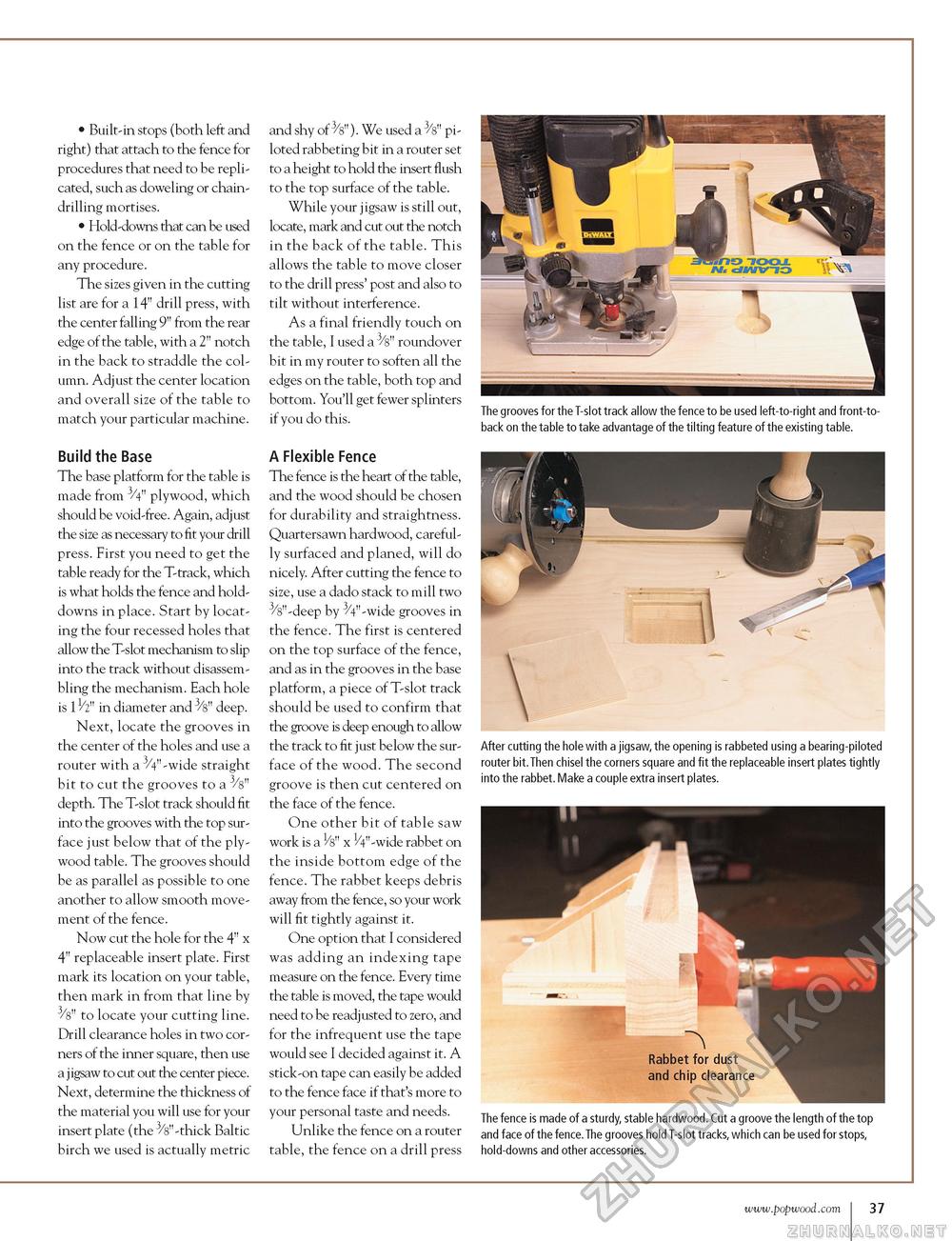

• Built-in stops (both left and right) that attach to the fence for procedures that need to be replicated, such as doweling or chain-drilling mortises. • Hold-downs that can be used on the fence or on the table for any procedure. The sizes given in the cutting list are for a 14" drill press, with the center falling 9" from the rear edge of the table, with a 2" notch in the back to straddle the column. Adjust the center location and overall size of the table to match your particular machine. Build the Base The base platform for the table is made from 3/4" plywood, which should be void-free. Again, adjust the size as necessary to fit your drill press. First you need to get the table ready for the T-track, which is what holds the fence and hold-downs in place. Start by locating the four recessed holes that allow the T-slot mechanism to slip into the track without disassembling the mechanism. Each hole is 11/2" in diameter and 3/s" deep. Next, locate the grooves in the center of the holes and use a router with a 3/4"-wide straight bit to cut the grooves to a 3/s" depth. The T-slot track should fit into the grooves with the top surface just below that of the plywood table. The grooves should be as parallel as possible to one another to allow smooth movement of the fence. Now cut the hole for the 4" x 4" replaceable insert plate. First mark its location on your table, then mark in from that line by 3/8" to locate your cutting line. Drill clearance holes in two corners of the inner square, then use a jigsaw to cut out the center piece. Next, determine the thickness of the material you will use for your insert plate (the 3/8"-thick Baltic birch we used is actually metric and shy of 3/8"). We used a 3/8" piloted rabbeting bit in a router set to a height to hold the insert flush to the top surface of the table. While your jigsaw is still out, locate, mark and cut out the notch in the back of the table. This allows the table to move closer to the drill press' post and also to tilt without interference. As a final friendly touch on the table, I used a 3/8" roundover bit in my router to soften all the edges on the table, both top and bottom. You'll get fewer splinters if you do this. A Flexible Fence The fence is the heart of the table, and the wood should be chosen for durability and straightness. Quartersawn hardwood, carefully surfaced and planed, will do nicely. After cutting the fence to size, use a dado stack to mill two 3/8"-deep by 3/4" -wide grooves in the fence. The first is centered on the top surface of the fence, and as in the grooves in the base platform, a piece of T-slot track should be used to confirm that the groove is deep enough to allow the track to fit just below the surface of the wood. The second groove is then cut centered on the face of the fence. One other bit of table saw work is a ^8" x ^V-wide rabbet on the inside bottom edge of the fence. The rabbet keeps debris away from the fence, so your work will fit tightly against it. One option that I considered was adding an indexing tape measure on the fence. Every time the table is moved, the tape would need to be readjusted to zero, and for the infrequent use the tape would see I decided against it. A stick-on tape can easily be added to the fence face if that's more to your personal taste and needs. Unlike the fence on a router table, the fence on a drill press The grooves for the T-slot track allow the fence to be used left-to-right and front-to-back on the table to take advantage of the tilting feature of the existing table. After cutting the hole with a jigsaw, the opening is rabbeted using a bearing-piloted router bit. Then chisel the corners square and fit the replaceable insert plates tightly into the rabbet. Make a couple extra insert plates. The fence is made of a sturdy, stable hardwood. Cut a groove the length of the top and face of the fence.The grooves hold T-slot tracks, which can be used for stops, hold-downs and other accessories. 37 |