Popular Woodworking 2003-04 № 133, страница 49

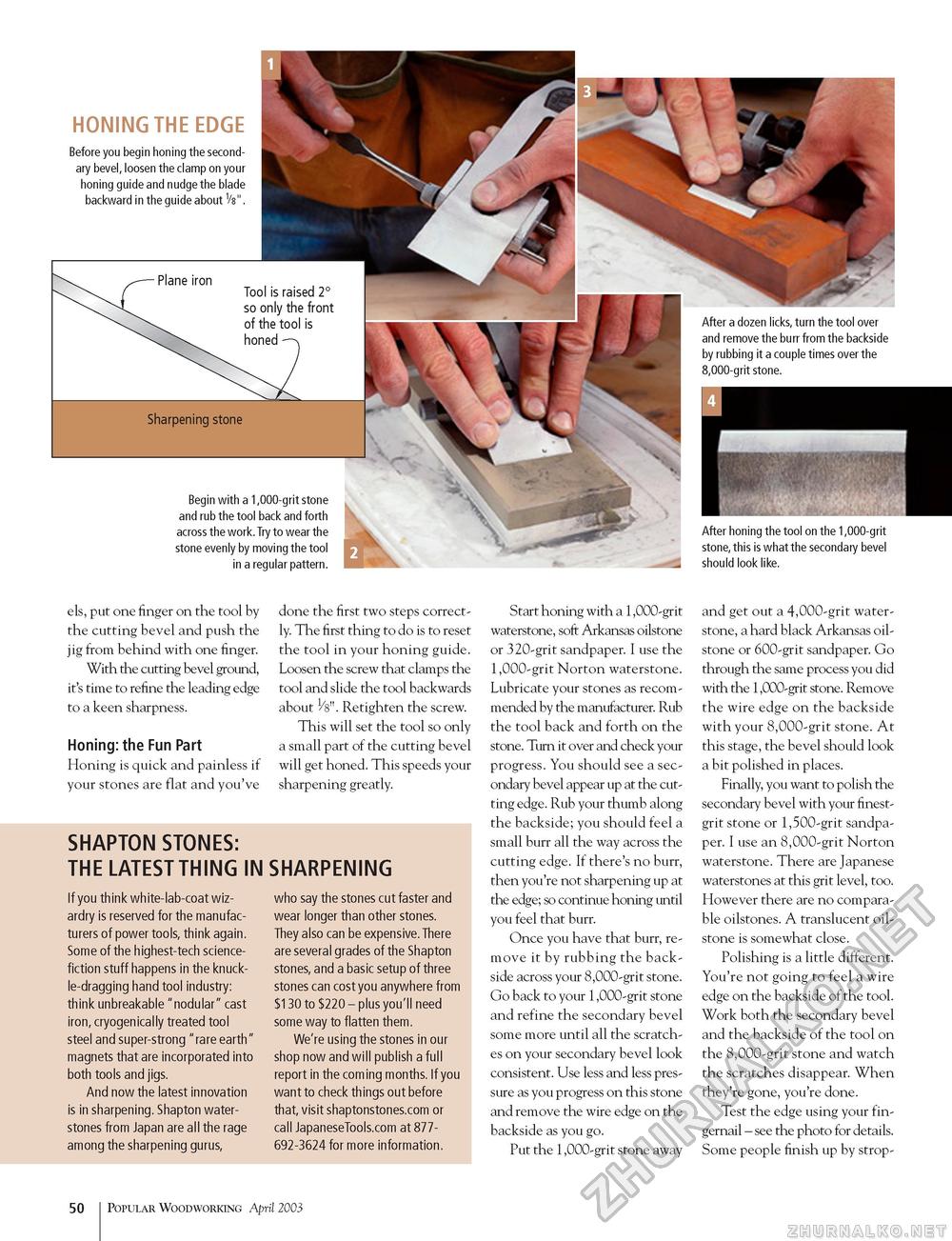

Tri HONING THE EDGE Before you begin honing the secondary bevel, loosen the clamp on your honing guide and nudge the blade backward in the guide about Vs". Plane iron Tool is raised 2° so only the front of the tool is honed Begin with a 1,000-grit stone and rub the tool back and forth across the work. Try to wear the stone evenly by moving the tool in a regular pattern. After a dozen licks, turn the tool over and remove the burr from the backside by rubbing it a couple times over the 8,000-grit stone. After honing the tool on the 1,000-grit stone, this is what the secondary bevel should look like. els, put one finger on the tool by the cutting bevel and push the jig from behind with one finger. With the cutting bevel ground, it's time to refine the leading edge to a keen sharpness. Honing: the Fun Part Honing is quick and painless if your stones are flat and you've If you think white-lab-coat wizardry is reserved for the manufacturers of power tools, think again. Some of the highest-tech science-fiction stuff happens in the knuckle-dragging hand tool industry: think unbreakable "nodular" cast iron, cryogenically treated tool steel and super-strong "rare earth" magnets that are incorporated into both tools and jigs. And now the latest innovation is in sharpening. Shapton water-stones from Japan are all the rage among the sharpening gurus, done the first two steps correctly. The first thing to do is to reset the tool in your honing guide. Loosen the screw that clamps the tool and slide the tool backwards about 1/8". Retighten the screw. This will set the tool so only a small part of the cutting bevel will get honed. This speeds your sharpening greatly. who say the stones cut faster and wear longer than other stones. They also can be expensive. There are several grades of the Shapton stones, and a basic setup of three stones can cost you anywhere from $130 to $220 - plus you'll need some way to flatten them. We're using the stones in our shop now and will publish a full report in the coming months. If you want to check things out before that, visit shaptonstones.com or call JapaneseTools.com at 877692-3624 for more information. Start honing with a 1,000-grit waterstone, soft Arkansas oilstone or 320-grit sandpaper. I use the 1,000-grit Norton waterstone. Lubricate your stones as recommended by the manufacturer. Rub the tool back and forth on the stone. Turn it over and check your progress. You should see a secondary bevel appear up at the cutting edge. Rub your thumb along the backside; you should feel a small burr all the way across the cutting edge. If there's no burr, then you're not sharpening up at the edge; so continue honing until you feel that burr. Once you have that burr, remove it by rubbing the backside across your 8,000-grit stone. Go back to your 1,000-grit stone and refine the secondary bevel some more until all the scratches on your secondary bevel look consistent. Use less and less pressure as you progress on this stone and remove the wire edge on the backside as you go. Put the 1,000-grit stone away and get out a 4,000-grit water-stone, a hard black Arkansas oilstone or 600-grit sandpaper. Go through the same process you did with the 1,000-grit stone. Remove the wire edge on the backside with your 8,000-grit stone. At this stage, the bevel should look a bit polished in places. Finally, you want to polish the secondary bevel with your finest-grit stone or 1,500-grit sandpaper. I use an 8,000-grit Norton waterstone. There are Japanese waterstones at this grit level, too. However there are no comparable oilstones. A translucent oilstone is somewhat close. Polishing is a little different. You're not going to feel a wire edge on the backside of the tool. Work both the secondary bevel and the backside of the tool on the 8,000-grit stone and watch the scratches disappear. When they're gone, you're done. Test the edge using your fingernail - see the photo for details. Some people finish up by strop- SHAPTON STONES: THE LATEST THING IN SHARPENING 50 Popular Woodworking April 2003 |