Popular Woodworking 2003-11 № 137, страница 56

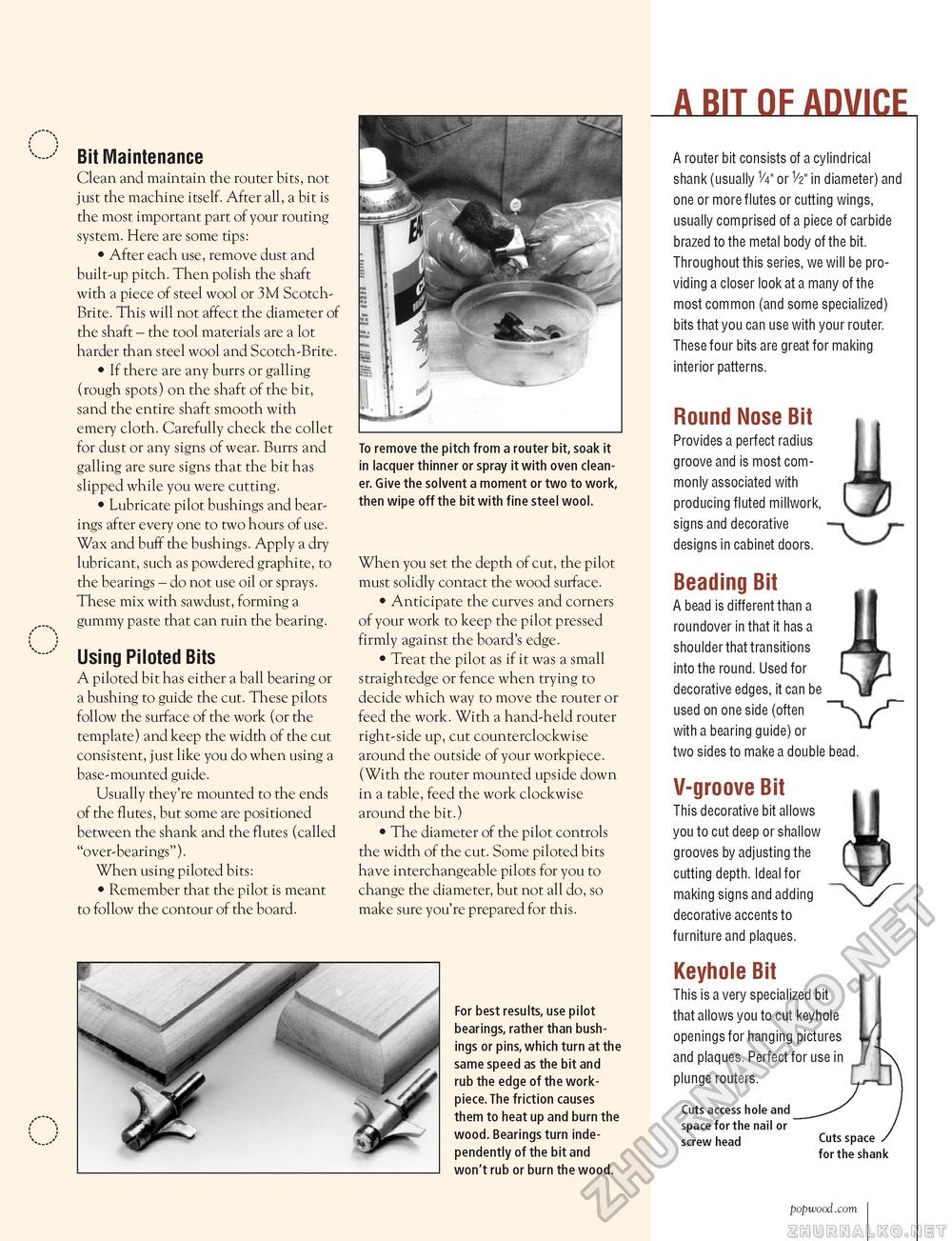

Bit Maintenance Clean and maintain the router bits, not just the machine itself. After all, a bit is the most important part of your routing system. Here are some tips: • After each use, remove dust and built-up pitch. Then polish the shaft with a piece of steel wool or 3M Scotch-Brite. This will not affect the diameter of the shaft - the tool materials are a lot harder than steel wool and Scotch-Brite. • If there are any burrs or galling (rough spots) on the shaft of the bit, sand the entire shaft smooth with emery cloth. Carefully check the collet for dust or any signs of wear. Burrs and galling are sure signs that the bit has slipped while you were cutting. • Lubricate pilot bushings and bearings after every one to two hours of use. Wax and buff the bushings. Apply a dry lubricant, such as powdered graphite, to the bearings - do not use oil or sprays. These mix with sawdust, forming a gummy paste that can ruin the bearing. Using Piloted Bits A piloted bit has either a ball bearing or a bushing to guide the cut. These pilots follow the surface of the work (or the template) and keep the width of the cut consistent, just like you do when using a base-mounted guide. Usually they're mounted to the ends of the flutes, but some are positioned between the shank and the flutes (called "over-bearings"). When using piloted bits: • Remember that the pilot is meant to follow the contour of the board. To remove the pitch from a router bit, soak it in lacquer thinner or spray it with oven cleaner. Give the solvent a moment or two to work, then wipe off the bit with fine steel wool. When you set the depth of cut, the pilot must solidly contact the wood surface. • Anticipate the curves and corners of your work to keep the pilot pressed firmly against the board's edge. • Treat the pilot as if it was a small straightedge or fence when trying to decide which way to move the router or feed the work. With a hand-held router right-side up, cut counterclockwise around the outside of your workpiece. (With the router mounted upside down in a table, feed the work clockwise around the bit.) • The diameter of the pilot controls the width of the cut. Some piloted bits have interchangeable pilots for you to change the diameter, but not all do, so make sure you're prepared for this. For best results, use pilot bearings, rather than bushings or pins, which turn at the same speed as the bit and rub the edge of the work-piece. The friction causes them to heat up and burn the wood. Bearings turn independently of the bit and won't rub or burn the wood. A BIT OF ADVICE A router bit consists of a cylindrical shank (usually 1/4" or 1/2" in diameter) and one or more flutes or cutting wings, usually comprised of a piece of carbide brazed to the metal body of the bit. Throughout this series, we will be providing a closer look at a many of the most common (and some specialized) bits that you can use with your router. These four bits are great for making interior patterns. Round Nose Bit Provides a perfect radius groove and is most commonly associated with producing fluted millwork, signs and decorative designs in cabinet doors. Beading Bit A bead is different than a roundover in that it has a shoulder that transitions into the round. Used for decorative edges, it can be used on one side (often with a bearing guide) or two sides to make a double bead V-groove Bit This decorative bit allows you to cut deep or shallow grooves by adjusting the cutting depth. Ideal for making signs and adding decorative accents to furniture and plaques. Keyhole Bit This is a very specialized bit that allows you to cut keyhole openings for hanging pictures and plaques. Perfect for use in plunge routers. Cuts access hole and space for the nail or screw head Cuts space for the shank popwood.com 56 |