Popular Woodworking 2003-11 № 137, страница 62

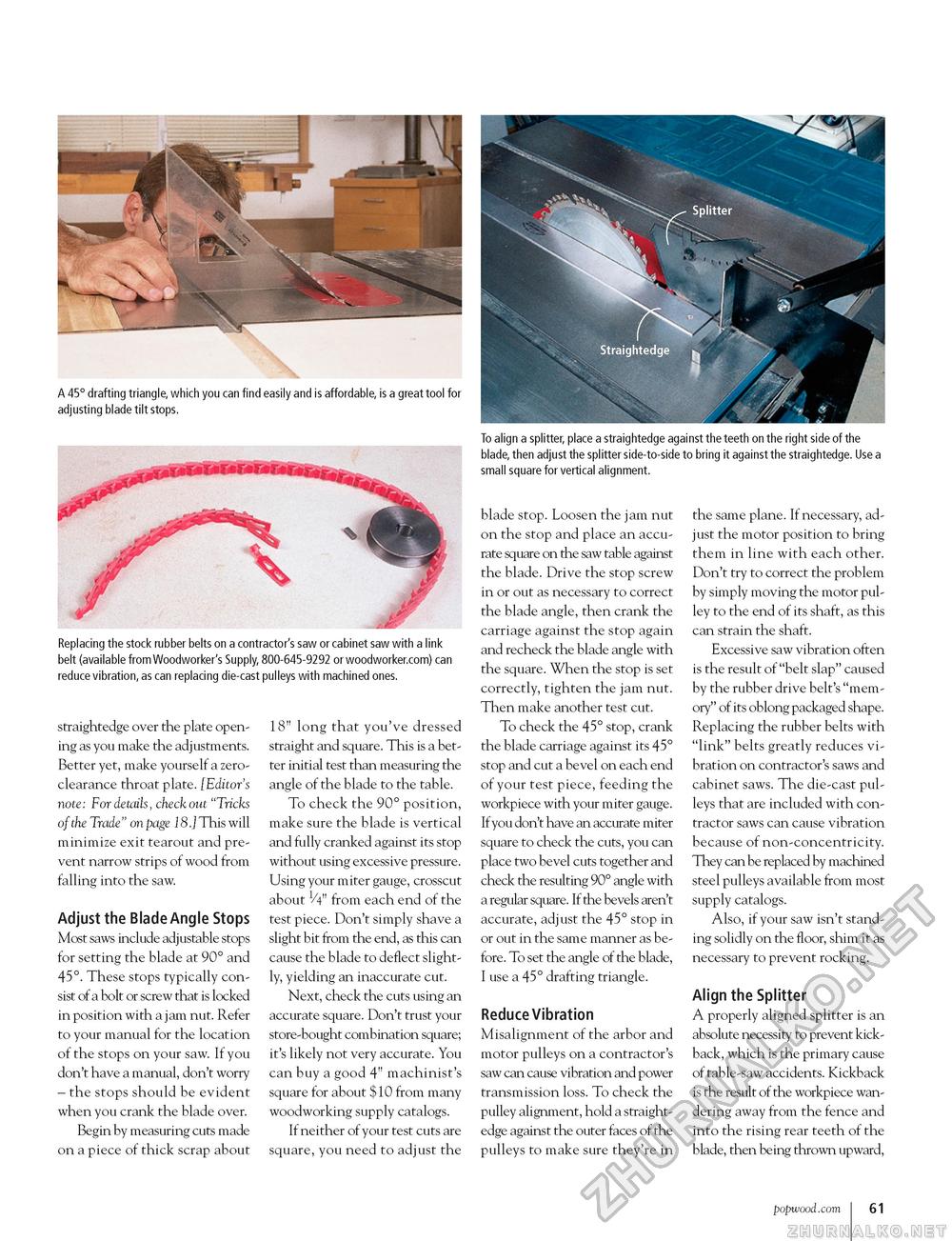

To align a splitter, place a straightedge against the teeth on the right side of the blade, then adjust the splitter side-to-side to bring it against the straightedge. Use a small square for vertical alignment. Replacing the stock rubber belts on a contractor's saw or cabinet saw with a link belt (available from Woodworker's Supply, 800-645-9292 or woodworker.com) can reduce vibration, as can replacing die-cast pulleys with machined ones. straightedge over the plate opening as you make the adjustments. Better yet, make yourself a zero-clearance throat plate. [Editor's note: For details, check out "Tricks of the Trade" on page 18.] This will minimize exit tearout and prevent narrow strips of wood from falling into the saw. Adjust the Blade Angle Stops Most saws include adjustable stops for setting the blade at 90° and 45°. These stops typically consist of a bolt or screw that is locked in position with a jam nut. Refer to your manual for the location of the stops on your saw. If you don't have a manual, don't worry - the stops should be evident when you crank the blade over. Begin by measuring cuts made on a piece of thick scrap about 18" long that you've dressed straight and square. This is a better initial test than measuring the angle of the blade to the table. To check the 90° position, make sure the blade is vertical and fully cranked against its stop without using excessive pressure. Using your miter gauge, crosscut about 1/4" from each end of the test piece. Don't simply shave a slight bit from the end, as this can cause the blade to deflect slightly, yielding an inaccurate cut. Next, check the cuts using an accurate square. Don't trust your store-bought combination square; it's likely not very accurate. You can buy a good 4" machinist's square for about $10 from many woodworking supply catalogs. If neither of your test cuts are square, you need to adjust the blade stop. Loosen the jam nut on the stop and place an accurate square on the saw table against the blade. Drive the stop screw in or out as necessary to correct the blade angle, then crank the carriage against the stop again and recheck the blade angle with the square. When the stop is set correctly, tighten the jam nut. Then make another test cut. To check the 45° stop, crank the blade carriage against its 45° stop and cut a bevel on each end of your test piece, feeding the workpiece with your miter gauge. If you don't have an accurate miter square to check the cuts, you can place two bevel cuts together and check the resulting 90° angle with a regular square. If the bevels aren't accurate, adjust the 45° stop in or out in the same manner as before. To set the angle of the blade, I use a 45° drafting triangle. Reduce Vibration Misalignment of the arbor and motor pulleys on a contractor's saw can cause vibration and power transmission loss. To check the pulley alignment, hold a straightedge against the outer faces of the pulleys to make sure they're in the same plane. If necessary, adjust the motor position to bring them in line with each other. Don't try to correct the problem by simply moving the motor pulley to the end of its shaft, as this can strain the shaft. Excessive saw vibration often is the result of "belt slap" caused by the rubber drive belt's "memory" of its oblong packaged shape. Replacing the rubber belts with "link" belts greatly reduces vibration on contractor's saws and cabinet saws. The die-cast pulleys that are included with contractor saws can cause vibration because of non-concentricity. They can be replaced by machined steel pulleys available from most supply catalogs. Also, if your saw isn't standing solidly on the floor, shim it as necessary to prevent rocking. Align the Splitter A properly aligned splitter is an absolute necessity to prevent kickback, which is the primary cause of table-saw accidents. Kickback is the result of the workpiece wandering away from the fence and into the rising rear teeth of the blade, then being thrown upward, popwood.com 61 |