Popular Woodworking 2003-12 № 138, страница 43

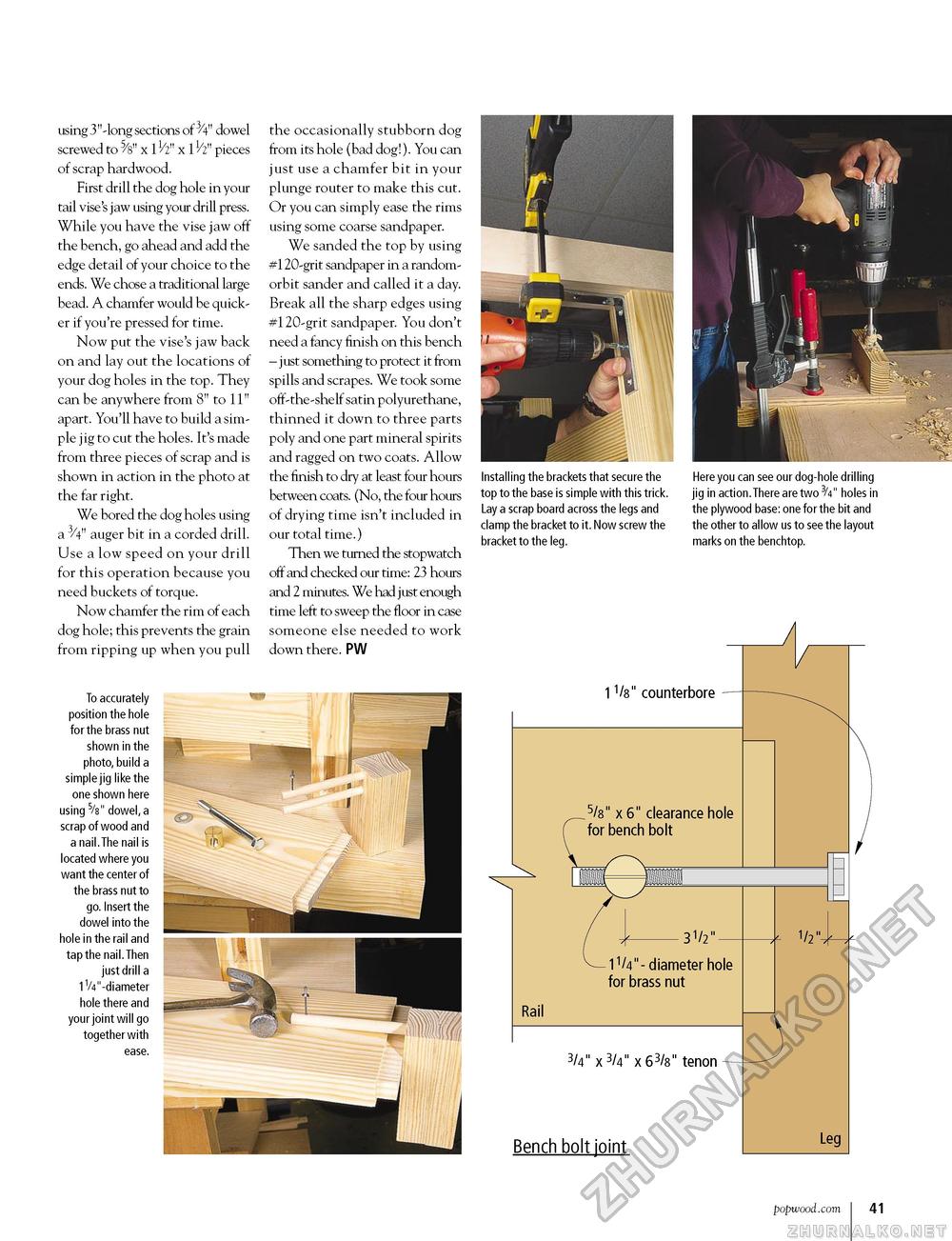

using 3"-long sections of 3/4" dowel screwed to 5/s" x 11/2" x 11/2" pieces of scrap hardwood. First drill the dog hole in your tail vise's jaw using your drill press. While you have the vise jaw off the bench, go ahead and add the edge detail of your choice to the ends. We chose a traditional large bead. A chamfer would be quicker if you're pressed for time. Now put the vise's jaw back on and lay out the locations of your dog holes in the top. They can be anywhere from 8" to 11" apart. You'll have to build a simple jig to cut the holes. It's made from three pieces of scrap and is shown in action in the photo at the far right. We bored the dog holes using a 3/4" auger bit in a corded drill. Use a low speed on your drill for this operation because you need buckets of torque. Now chamfer the rim of each dog hole; this prevents the grain from ripping up when you pull the occasionally stubborn dog from its hole (bad dog!). You can just use a chamfer bit in your plunge router to make this cut. Or you can simply ease the rims using some coarse sandpaper. We sanded the top by using #120-grit sandpaper in a random-orbit sander and called it a day. Break all the sharp edges using #120-grit sandpaper. You don't need a fancy finish on this bench - just something to protect it from spills and scrapes. We took some off-the-shelf satin polyurethane, thinned it down to three parts poly and one part mineral spirits and ragged on two coats. Allow the finish to dry at least four hours between coats. (No, the four hours of drying time isn't included in our total time.) Then we turned the stopwatch off and checked our time: 23 hours and 2 minutes. We had just enough time left to sweep the floor in case someone else needed to work down there. PW Installing the brackets that secure the top to the base is simple with this trick. Lay a scrap board across the legs and clamp the bracket to it. Now screw the bracket to the leg. Here you can see our dog-hole drilling jig in action.There are two 3/4" holes in the plywood base: one for the bit and the other to allow us to see the layout marks on the benchtop. 11/8" counterbore 5/8" x 6" clearance hole for bench bolt \-31/2" — 11/4"- diameter hole for brass nut Rail 3/4" x 3/4" x 63/8" tenon Bench bolt joint 1/2% Leg popwood.com 73 |