Popular Woodworking 2004-02 № 139, страница 46

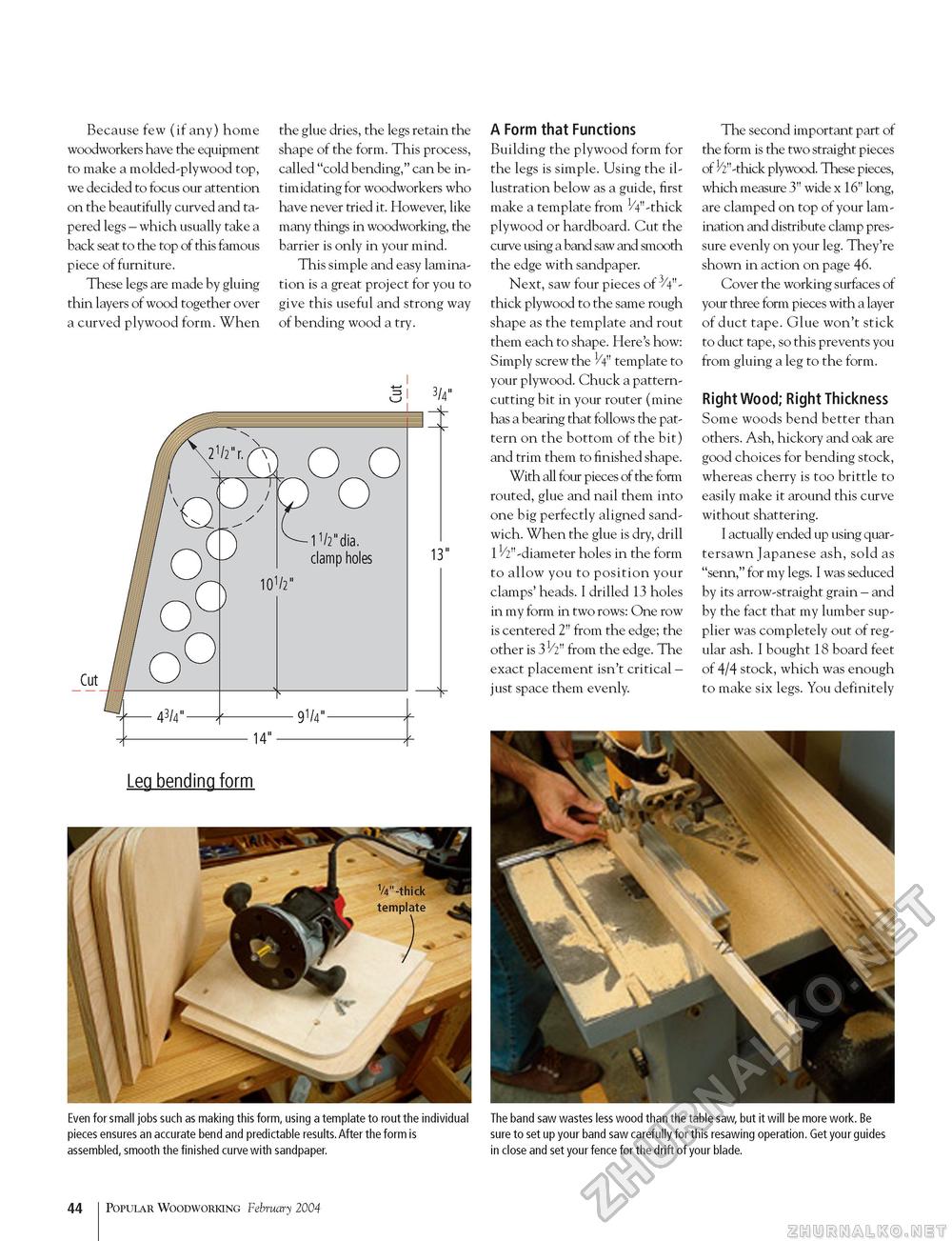

Because few (if any) home woodworkers have the equipment to make a molded-plywood top, we decided to focus our attention on the beautifully curved and tapered legs - which usually take a back seat to the top of this famous piece of furniture. These legs are made by gluing thin layers of wood together over a curved plywood form. When the glue dries, the legs retain the shape of the form. This process, called "cold bending," can be intimidating for woodworkers who have never tried it. However, like many things in woodworking, the barrier is only in your mind. This simple and easy lamination is a great project for you to give this useful and strong way of bending wood a try. C 3/4" Cut A Form that Functions Building the plywood form for the legs is simple. Using the illustration below as a guide, first make a template from 1/4"-thick plywood or hardboard. Cut the curve using a band saw and smooth the edge with sandpaper. Next, saw four pieces of 3/4"-thick plywood to the same rough shape as the template and rout them each to shape. Here's how: Simply screw the 1/4" template to your plywood. Chuck a pattern-cutting bit in your router (mine has a bearing that follows the pattern on the bottom of the bit) and trim them to finished shape. With all four pieces of the form routed, glue and nail them into one big perfectly aligned sandwich. When the glue is dry, drill -diameter holes in the form to allow you to position your clamps' heads. I drilled 13 holes in my form in two rows: One row is centered 2" from the edge; the other is 31/2" from the edge. The exact placement isn't critical -just space them evenly. The second important part of the form is the two straight pieces of h" -thick plywood. These pieces, which measure 3" wide x 16" long, are clamped on top of your lamination and distribute clamp pressure evenly on your leg. They're shown in action on page 46. Cover the working surfaces of your three form pieces with a layer of duct tape. Glue won't stick to duct tape, so this prevents you from gluing a leg to the form. Right Wood; Right Thickness Some woods bend better than others. Ash, hickory and oak are good choices for bending stock, whereas cherry is too brittle to easily make it around this curve without shattering. I actually ended up using quar-tersawn Japanese ash, sold as "senn," for my legs. I was seduced by its arrow-straight grain - and by the fact that my lumber supplier was completely out of regular ash. I bought 18 board feet of 4/4 stock, which was enough to make six legs. You definitely Leg bending form Even for small jobs such as making this form, using a template to rout the individual pieces ensures an accurate bend and predictable results.After the form is assembled, smooth the finished curve with sandpaper. The band saw wastes less wood than the table saw, but it will be more work. Be sure to set up your band saw carefully for this resawing operation. Get your guides in close and set your fence for the drift of your blade. 44 Popular Woodworking February 2004 |