Popular Woodworking 2004-02 № 139, страница 53

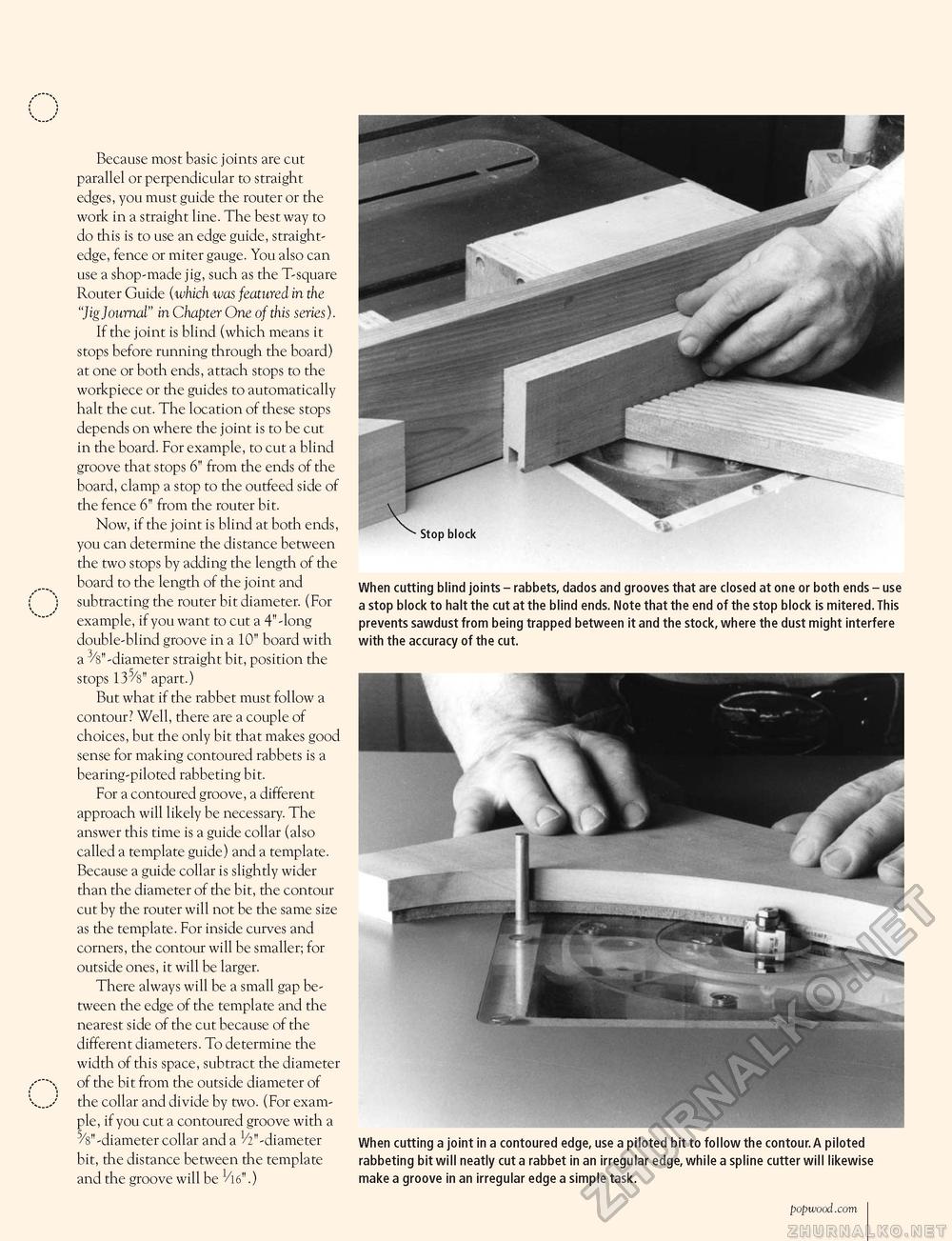

Because most basic joints are cut parallel or perpendicular to straight edges, you must guide the router or the work in a straight line. The best way to do this is to use an edge guide, straightedge, fence or miter gauge. You also can use a shop-made jig, such as the T-square Router Guide (which was featured in the "Jig Journal" in Chapter One of this series). If the joint is blind (which means it stops before running through the board) at one or both ends, attach stops to the workpiece or the guides to automatically halt the cut. The location of these stops depends on where the joint is to be cut in the board. For example, to cut a blind groove that stops 6" from the ends of the board, clamp a stop to the outfeed side of the fence 6" from the router bit. Now, if the joint is blind at both ends, you can determine the distance between the two stops by adding the length of the board to the length of the joint and subtracting the router bit diameter. (For example, if you want to cut a 4"-long double-blind groove in a 10" board with a 3/8"-diameter straight bit, position the stops 135/8" apart.) But what if the rabbet must follow a contour? Well, there are a couple of choices, but the only bit that makes good sense for making contoured rabbets is a bearing-piloted rabbeting bit. For a contoured groove, a different approach will likely be necessary. The answer this time is a guide collar (also called a template guide) and a template. Because a guide collar is slightly wider than the diameter of the bit, the contour cut by the router will not be the same size as the template. For inside curves and corners, the contour will be smaller; for outside ones, it will be larger. There always will be a small gap between the edge of the template and the nearest side of the cut because of the different diameters. To determine the width of this space, subtract the diameter .....of the bit from the outside diameter of K...J the collar and divide by two. (For example, if you cut a contoured groove with a 5/8"-diameter collar and a ^"-diameter bit, the distance between the template and the groove will be 1/i6".) When cutting blind joints - rabbets, dados and grooves that are closed at one or both ends - use a stop block to halt the cut at the blind ends. Note that the end of the stop block is mitered. This prevents sawdust from being trapped between it and the stock, where the dust might interfere with the accuracy of the cut. When cutting a joint in a contoured edge, use a piloted bit to follow the contour.A piloted rabbeting bit will neatly cut a rabbet in an irregular edge, while a spline cutter will likewise make a groove in an irregular edge a simple task. popwood.com 53 |