Popular Woodworking 2004-02 № 139, страница 77

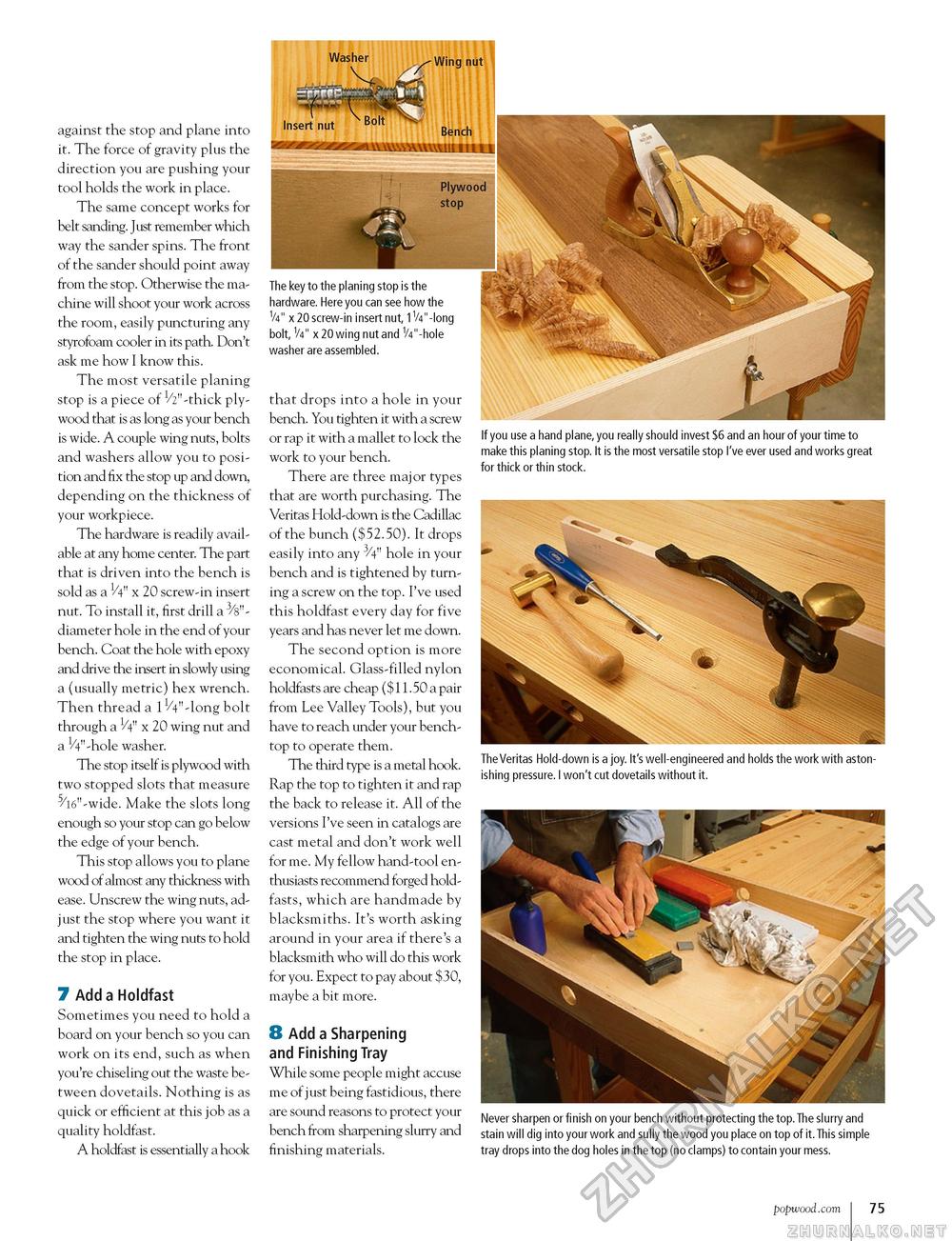

against the stop and plane into it. The force of gravity plus the direction you are pushing your tool holds the work in place. The same concept works for belt sanding. Just remember which way the sander spins. The front of the sander should point away from the stop. Otherwise the machine will shoot your work across the room, easily puncturing any styrofoam cooler in its path. Don't ask me how I know this. The most versatile planing stop is a piece of 1/2"-thick plywood that is as long as your bench is wide. A couple wing nuts, bolts and washers allow you to position and fix the stop up and down, depending on the thickness of your workpiece. The hardware is readily available at any home center. The part that is driven into the bench is sold as a V4" x 20 screw-in insert nut. To install it, first drill a 3/s"-diameter hole in the end of your bench. Coat the hole with epoxy and drive the insert in slowly using a (usually metric) hex wrench. Then thread a 1V4" -long bolt through a V4" x 20 wing nut and a 1/4"-hole washer. The stop itself is plywood with two stopped slots that measure 5/l6"-wide. Make the slots long enough so your stop can go below the edge of your bench. This stop allows you to plane wood of almost any thickness with ease. Unscrew the wing nuts, adjust the stop where you want it and tighten the wing nuts to hold the stop in place. 7 Add a Holdfast Sometimes you need to hold a board on your bench so you can work on its end, such as when you're chiseling out the waste between dovetails. Nothing is as quick or efficient at this job as a quality holdfast. A holdfast is essentially a hook The key to the planing stop is the hardware. Here you can see how the V4" x 20 screw-in insert nut, /'/V'-long bolt, V4" x 20 wing nut and '/V'-hole washer are assembled. that drops into a hole in your bench. You tighten it with a screw or rap it with a mallet to lock the work to your bench. There are three major types that are worth purchasing. The Veritas Hold-down is the Cadillac of the bunch ($52.50). It drops easily into any 3/4" hole in your bench and is tightened by turning a screw on the top. I've used this holdfast every day for five years and has never let me down. The second option is more economical. Glass-filled nylon holdfasts are cheap ($11.50 a pair from Lee Valley Tools), but you have to reach under your bench-top to operate them. The third type is a metal hook. Rap the top to tighten it and rap the back to release it. All of the versions I've seen in catalogs are cast metal and don't work well for me. My fellow hand-tool enthusiasts recommend forged holdfasts, which are handmade by blacksmiths. It's worth asking around in your area if there's a blacksmith who will do this work for you. Expect to pay about $30, maybe a bit more. 8 Add a Sharpening and Finishing Tray While some people might accuse me of just being fastidious, there are sound reasons to protect your bench from sharpening slurry and finishing materials. If you use a hand plane, you really should invest $6 and an hour of your time to make this planing stop. It is the most versatile stop I've ever used and works great for thick or thin stock. The Veritas Hold-down is a joy. It's well-engineered and holds the work with astonishing pressure. I won't cut dovetails without it. Never sharpen or finish on your bench without protecting the top.The slurry and stain will dig into your work and sully the wood you place on top of it. This simple tray drops into the dog holes in the top (no clamps) to contain your mess. popwood.com 75 |