Popular Woodworking 2004-08 № 142, страница 67

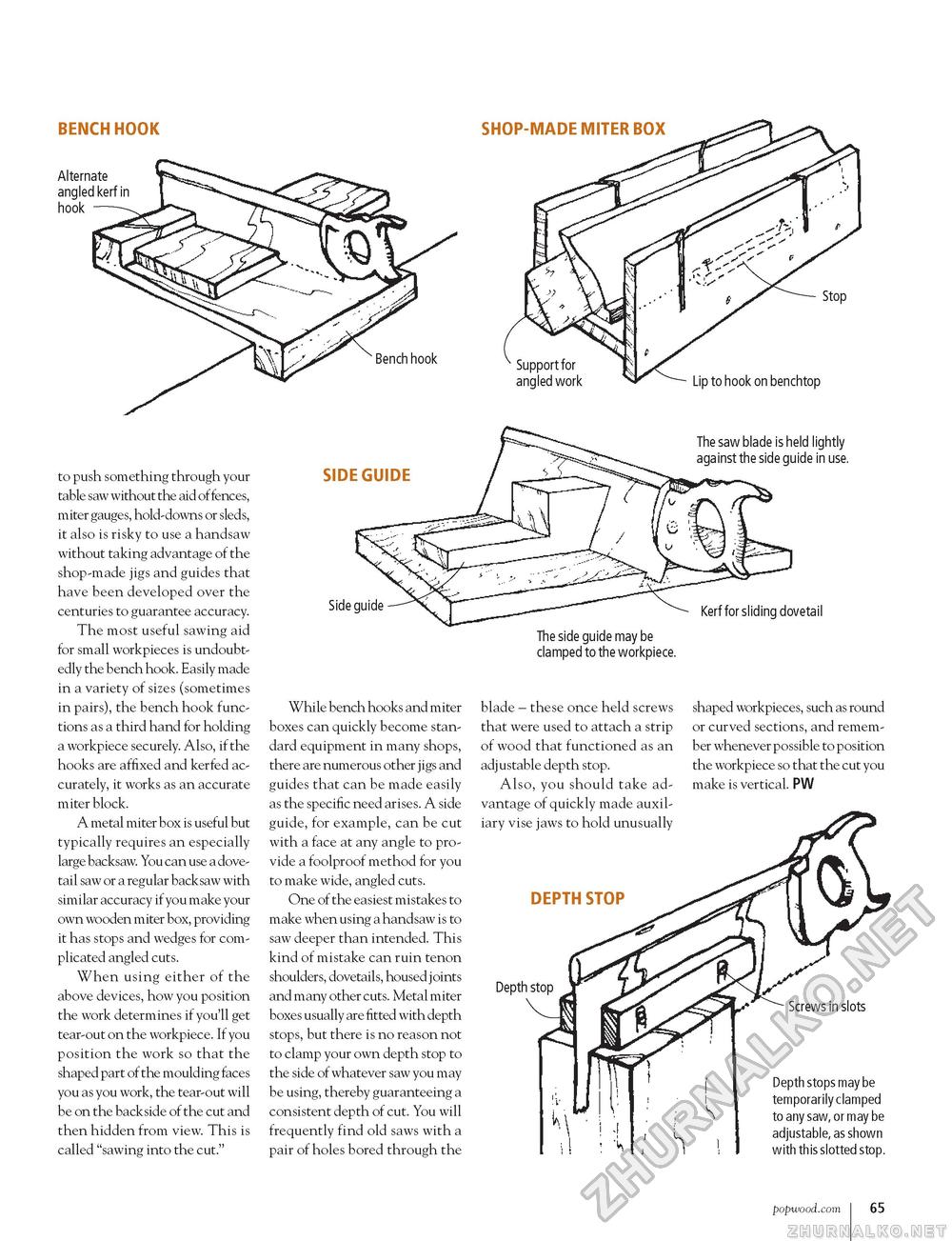

BENCH HOOK Alternate angled kerf in hook SHOP-MADE MITER BOX Bench hook Support for angled work to push something through your table saw without the aid of fences, miter gauges, hold-downs or sleds, it also is risky to use a handsaw without taking advantage of the shop-made jigs and guides that have been developed over the centuries to guarantee accuracy. The most useful sawing aid for small workpieces is undoubtedly the bench hook. Easily made in a variety of sizes (sometimes in pairs), the bench hook functions as a third hand for holding a workpiece securely. Also, if the hooks are affixed and kerfed accurately, it works as an accurate miter block. A metal miter box is useful but typically requires an especially large backsaw. You can use a dovetail saw or a regular backsaw with similar accuracy if you make your own wooden miter box, providing it has stops and wedges for complicated angled cuts. When using either of the above devices, how you position the work determines if you'll get tear-out on the workpiece. If you position the work so that the shaped part of the moulding faces you as you work, the tear-out will be on the backside of the cut and then hidden from view. This is called "sawing into the cut." SIDE GUIDE Lip to hook on benchtop The saw blade is held lightly against the side guide in use. Side guide Kerf for sliding dovetail While bench hooks and miter boxes can quickly become standard equipment in many shops, there are numerous other jigs and guides that can be made easily as the specific need arises. A side guide, for example, can be cut with a face at any angle to provide a foolproof method for you to make wide, angled cuts. One of the easiest mistakes to make when using a handsaw is to saw deeper than intended. This kind of mistake can ruin tenon shoulders, dovetails, housed joints and many other cuts. Metal miter boxes usually are fitted with depth stops, but there is no reason not to clamp your own depth stop to the side of whatever saw you may be using, thereby guaranteeing a consistent depth of cut. You will frequently find old saws with a pair of holes bored through the The side guide may be clamped to the workpiece. blade - these once held screws that were used to attach a strip of wood that functioned as an adjustable depth stop. Also, you should take advantage of quickly made auxiliary vise jaws to hold unusually shaped workpieces, such as round or curved sections, and remember whenever possible to position the workpiece so that the cut you make is vertical. PW DEPTH STOP Depth stop Screws in slots Depth stops may be temporarily clamped to any saw, or may be adjustable, as shown with this slotted stop. popwood.com 65 |