Popular Woodworking 2005-02 № 146, страница 72

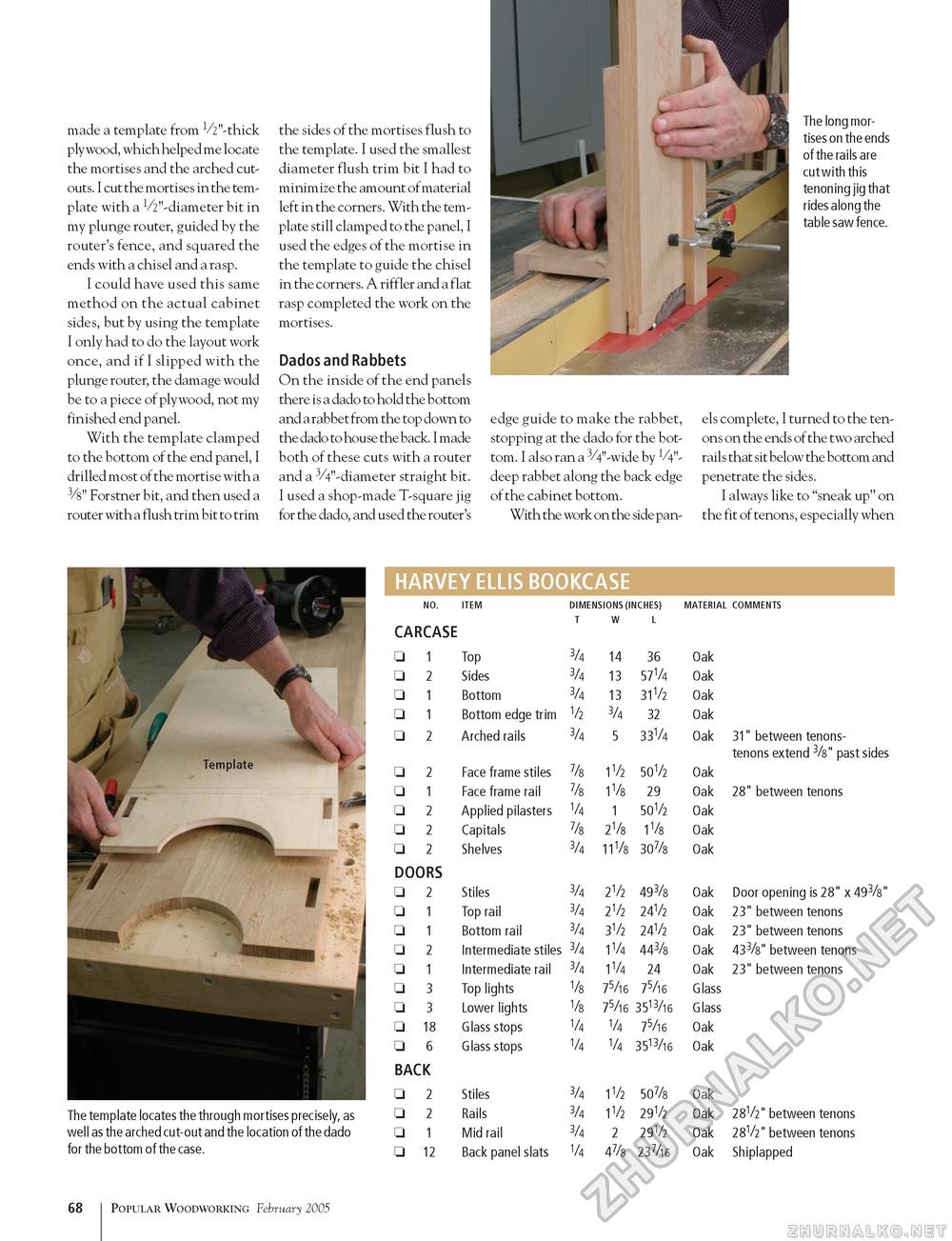

The long mortises on the ends of the rails are cut with this tenoning jig that rides along the table saw fence. made a template from V2"-thick plywood, which helped me locate the mortises and the arched cutouts. I cut the mortises in the template with a V2"-diameter bit in my plunge router, guided by the router's fence, and squared the ends with a chisel and a rasp. I could have used this same method on the actual cabinet sides, but by using the template I only had to do the layout work once, and if I slipped with the plunge router, the damage would be to a piece of plywood, not my finished end panel. With the template clamped to the bottom of the end panel, I drilled most of the mortise with a 3/8" Forstner bit, and then used a router with a flush trim bit to trim the sides of the mortises flush to the template. I used the smallest diameter flush trim bit I had to minimize the amount of material left in the corners. With the template still clamped to the panel, I used the edges of the mortise in the template to guide the chisel in the corners. A riff ler and a flat rasp completed the work on the mortises. Dados and Rabbets On the inside of the end panels there is a dado to hold the bottom and a rabbet from the top down to the dado to house the back. I made both of these cuts with a router and a 3/4"-diameter straight bit. I used a shop-made T-square jig for the dado, and used the router's edge guide to make the rabbet, stopping at the dado for the bottom. I also ran a 3/4"-wide by V4"-deep rabbet along the back edge of the cabinet bottom. With the work on the side pan- els complete, I turned to the tenons on the ends of the two arched rails that sit below the bottom and penetrate the sides. I always like to "sneak up" on the fit of tenons, especially when HARVEY ELLIS BOOKCASE The template locates the through mortises precisely, as well as the arched cut-out and the location of the dado for the bottom of the case.

68 Popular Woodworking February 2005 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||