Popular Woodworking 2005-04 № 147, страница 59

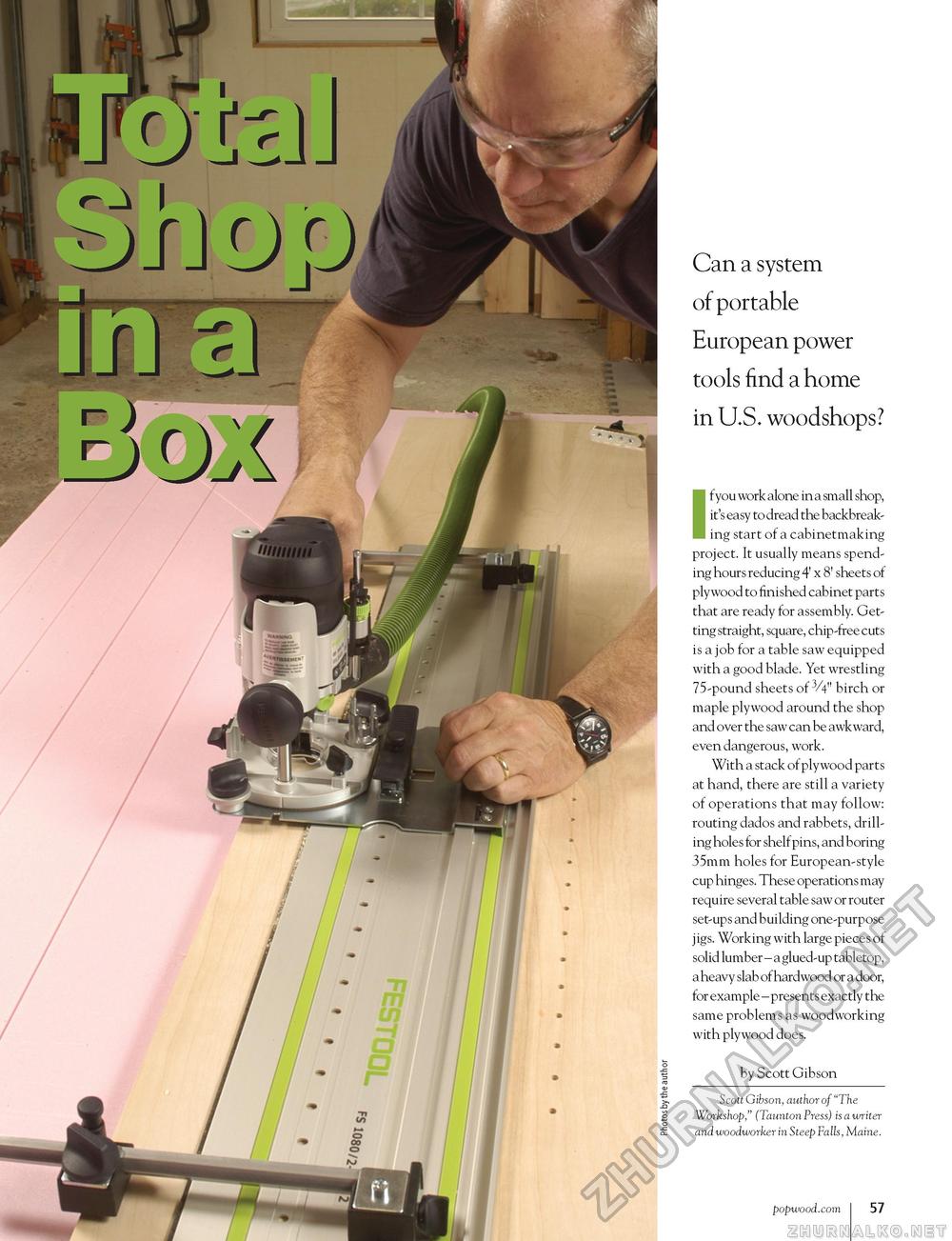

ShOp Can a system of portable European power tools find a home in U.S. woodshops? Ifyou work alone in a small shop, it's easy to dread the backbreak-ing start of a cabinetmaking project. It usually means spending hours reducing 4' x 8' sheets of plywood to finished cabinet parts that are ready for assembly. Getting straight, square, chip-free cuts is a job for a table saw equipped with a good blade. Yet wrestling 75-pound sheets of 3/4" birch or maple plywood around the shop and over the saw can be awkward, even dangerous, work. With a stack of plywood parts at hand, there are still a variety of operations that may follow: routing dados and rabbets, drilling holes for shelf pins, and boring 35mm holes for European-style cup hinges. These operations may require several table saw or router set-ups and building one-purpose jigs. Working with large pieces of solid lumber - a glued-up tabletop, a heavy slab ofhardwood or a door, for example - presents exactly the same problems as woodworking with plywood does. by Scott Gibson Scott Gibson, author of "The Workshop," (Taunton Press) is a writer and woodworker in Steep Falls, Maine. popwood.com 57 |