Popular Woodworking 2005-04 № 147, страница 57

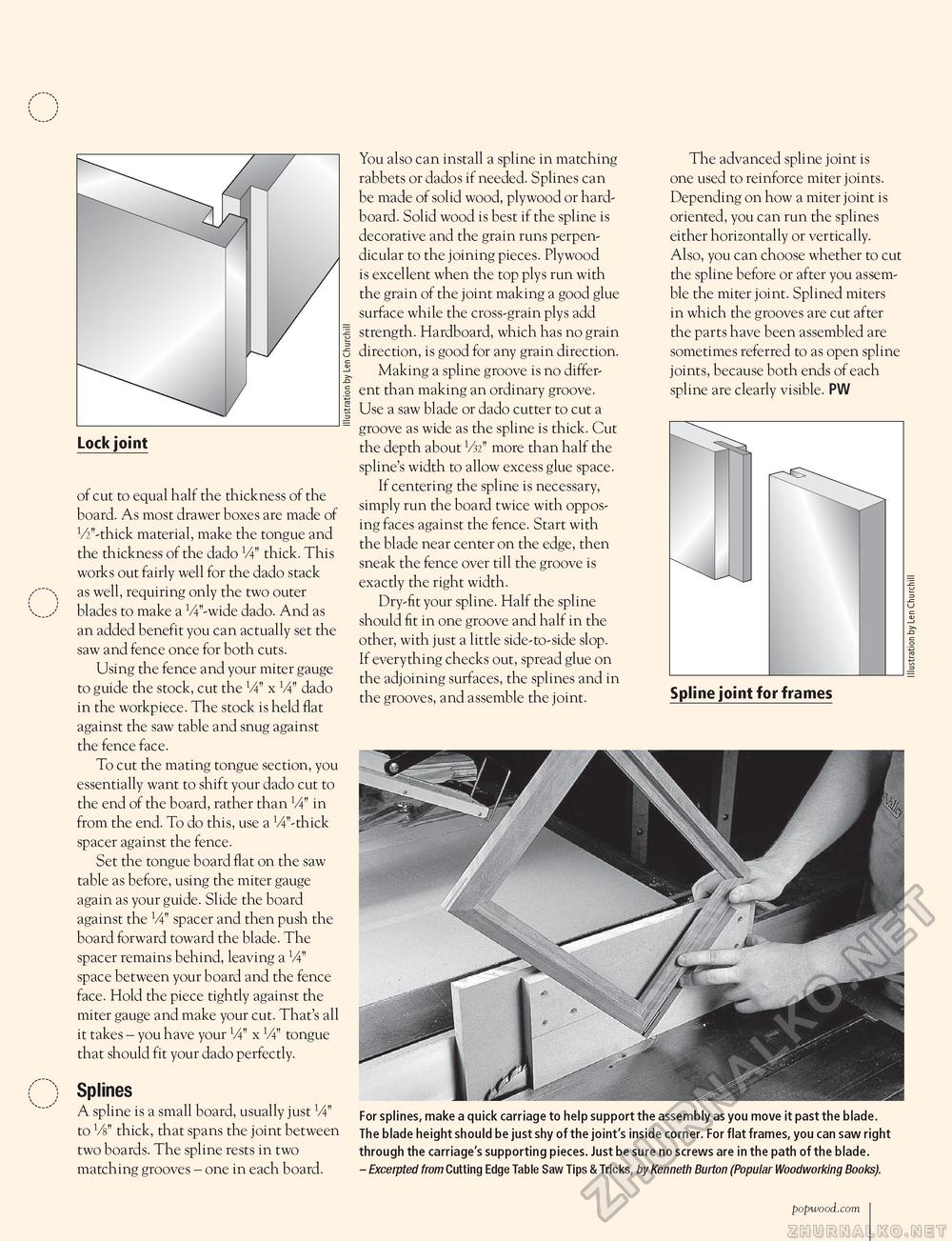

of cut to equal half the thickness of the board. As most drawer boxes are made of V2"-thick material, make the tongue and the thickness of the dado V4" thick. This works out fairly well for the dado stack as well, requiring only the two outer blades to make a V4"-wide dado. And as an added benefit you can actually set the saw and fence once for both cuts. Using the fence and your miter gauge to guide the stock, cut the V4" x V4" dado in the workpiece. The stock is held flat against the saw table and snug against the fence face. To cut the mating tongue section, you essentially want to shift your dado cut to the end of the board, rather than V4" in from the end. To do this, use a W-thick spacer against the fence. Set the tongue board flat on the saw table as before, using the miter gauge again as your guide. Slide the board against the V4" spacer and then push the board forward toward the blade. The spacer remains behind, leaving a V4" space between your board and the fence face. Hold the piece tightly against the miter gauge and make your cut. That's all it takes - you have your V4" x V4" tongue that should fit your dado perfectly. Splines A spline is a small board, usually just V4" to Vs" thick, that spans the joint between two boards. The spline rests in two matching grooves - one in each board. You also can install a spline in matching rabbets or dados if needed. Splines can be made of solid wood, plywood or hard-board. Solid wood is best if the spline is decorative and the grain runs perpendicular to the joining pieces. Plywood is excellent when the top plys run with the grain of the joint making a good glue surface while the cross-grain plys add strength. Hardboard, which has no grain direction, is good for any grain direction. Making a spline groove is no different than making an ordinary groove. Use a saw blade or dado cutter to cut a groove as wide as the spline is thick. Cut the depth about V32" more than half the spline's width to allow excess glue space. If centering the spline is necessary, simply run the board twice with opposing faces against the fence. Start with the blade near center on the edge, then sneak the fence over till the groove is exactly the right width. Dry-fit your spline. Half the spline should fit in one groove and half in the other, with just a little side-to-side slop. If everything checks out, spread glue on the adjoining surfaces, the splines and in the grooves, and assemble the joint. The advanced spline joint is one used to reinforce miter joints. Depending on how a miter joint is oriented, you can run the splines either horizontally or vertically. Also, you can choose whether to cut the spline before or after you assemble the miter joint. Splined miters in which the grooves are cut after the parts have been assembled are sometimes referred to as open spline joints, because both ends of each spline are clearly visible. PW Spline joint for frames For splines, make a quick carriage to help support the assembly as you move it past the blade. The blade height should be just shy of the joint's inside corner. For flat frames, you can saw right through the carriage's supporting pieces. Just be sure no screws are in the path of the blade. - Excerpted from Cutting Edge Table Saw Tips & Tricks, by Kenneth Burton (Popular Woodworking Books). popwood.com 57 |