Popular Woodworking 2005-04 № 147, страница 54

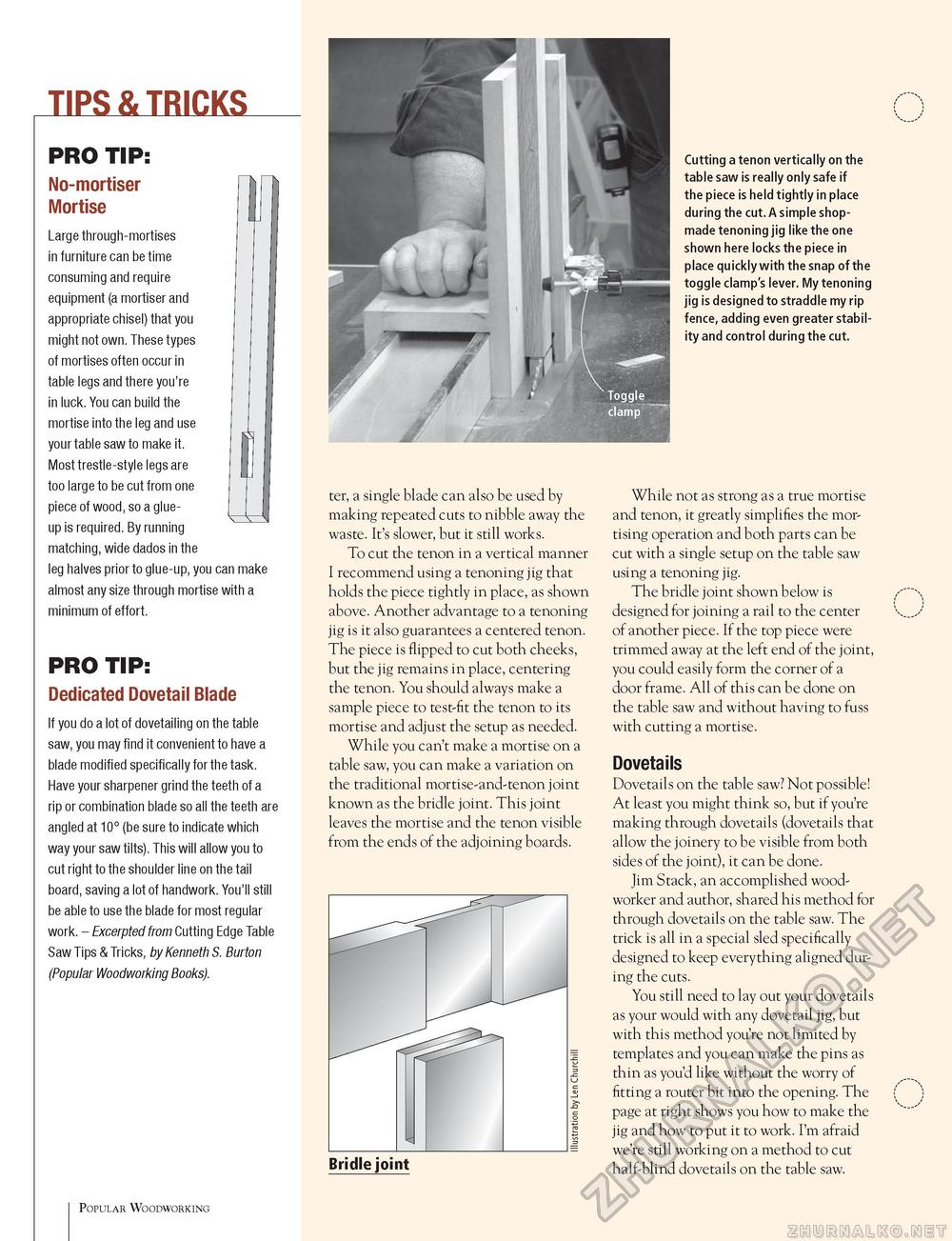

TIPS & TRICKS PRO TIP: No-mortiser Mortise Large through-mortises in furniture can be time consuming and require equipment (a mortiser and appropriate chisel) that you might not own. These types of mortises often occur in table legs and there you're in luck. You can build the mortise into the leg and use your table saw to make it. Most trestle-style legs are too large to be cut from one piece of wood, so a glue-up is required. By running matching, wide dados in the leg halves prior to glue-up, you can make almost any size through mortise with a minimum of effort. =k= PRO TIP: Dedicated Dovetail Blade If you do a lot of dovetailing on the table saw, you may find it convenient to have a blade modified specifically for the task. Have your sharpener grind the teeth of a rip or combination blade so all the teeth are angled at 10° (be sure to indicate which way your saw tilts). This will allow you to cut right to the shoulder line on the tail board, saving a lot of handwork. You'll still be able to use the blade for most regular work. - Excerpted from Cutting Edge Table Saw Tips & Tricks, by Kenneth S. Burton (Popular Woodworking Books). Cutting a tenon vertically on the table saw is really only safe if the piece is held tightly in place during the cut. A simple shop-made tenoning jig like the one shown here locks the piece in place quickly with the snap of the toggle clamp's lever. My tenoning jig is designed to straddle my rip fence, adding even greater stability and control during the cut. ter, a single blade can also be used by making repeated cuts to nibble away the waste. It's slower, but it still works. To cut the tenon in a vertical manner I recommend using a tenoning jig that holds the piece tightly in place, as shown above. Another advantage to a tenoning jig is it also guarantees a centered tenon. The piece is flipped to cut both cheeks, but the jig remains in place, centering the tenon. You should always make a sample piece to test-fit the tenon to its mortise and adjust the setup as needed. While you can't make a mortise on a table saw, you can make a variation on the traditional mortise-and-tenon joint known as the bridle joint. This joint leaves the mortise and the tenon visible from the ends of the adjoining boards. Bridle joint While not as strong as a true mortise and tenon, it greatly simplifies the mortising operation and both parts can be cut with a single setup on the table saw using a tenoning jig. The bridle joint shown below is designed for joining a rail to the center of another piece. If the top piece were trimmed away at the left end of the joint, you could easily form the corner of a door frame. All of this can be done on the table saw and without having to fuss with cutting a mortise. Dovetails Dovetails on the table saw? Not possible! At least you might think so, but if you're making through dovetails (dovetails that allow the joinery to be visible from both sides of the joint), it can be done. Jim Stack, an accomplished woodworker and author, shared his method for through dovetails on the table saw. The trick is all in a special sled specifically designed to keep everything aligned during the cuts. You still need to lay out your dovetails as your would with any dovetail jig, but with this method you're not limited by templates and you can make the pins as thin as you'd like without the worry of fitting a router bit into the opening. The page at right shows you how to make the jig and how to put it to work. I'm afraid we're still working on a method to cut half-blind dovetails on the table saw. Popular Woodworking |