Popular Woodworking 2005-04 № 147, страница 53

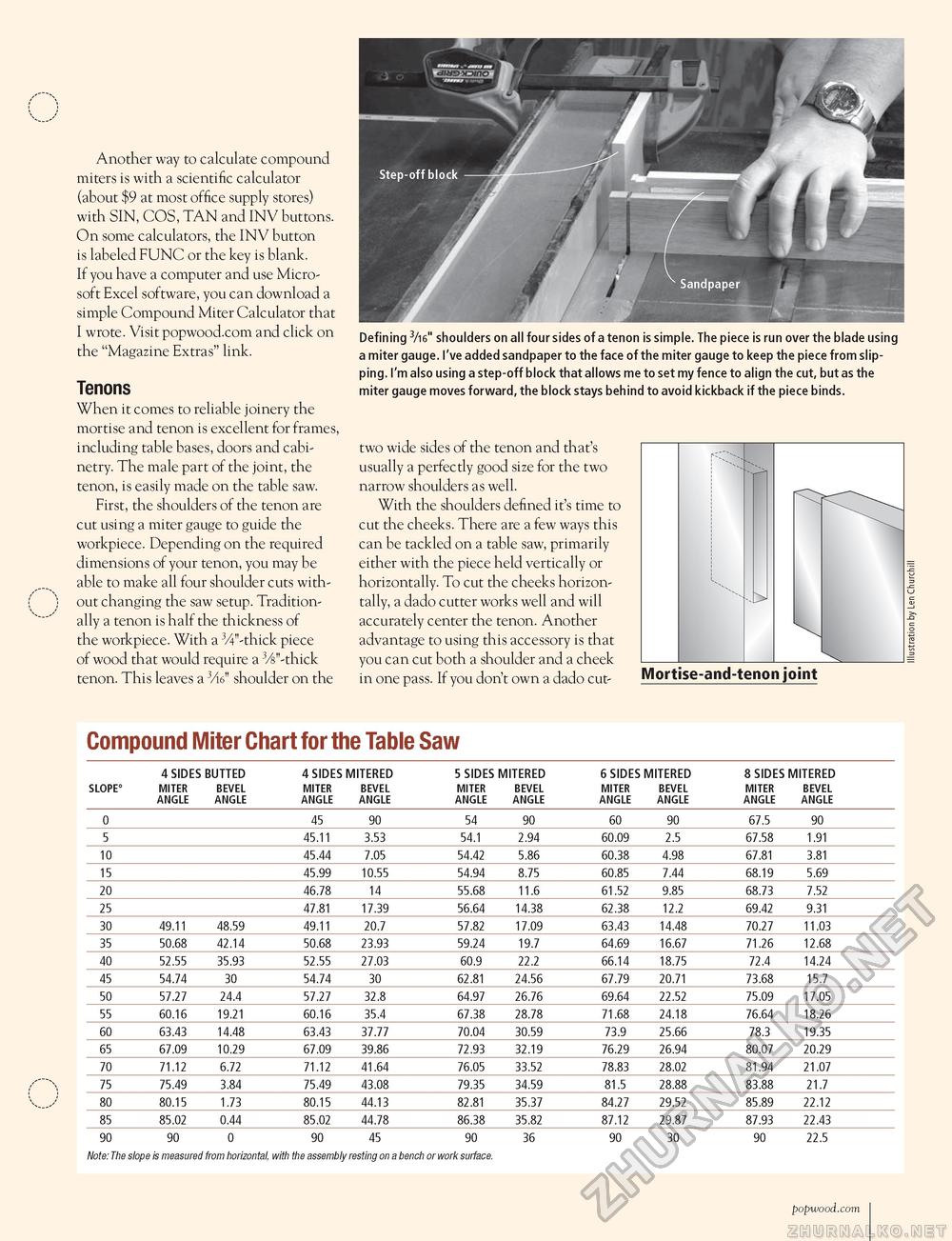

Another way to calculate compound miters is with a scientific calculator (about $9 at most office supply stores) with SIN, COS, TAN and INV buttons. On some calculators, the INV button is labeled FUNC or the key is blank. If you have a computer and use Microsoft Excel software, you can download a simple Compound Miter Calculator that I wrote. Visit popwood.com and click on the "Magazine Extras" link. Tenons When it comes to reliable joinery the mortise and tenon is excellent for frames, including table bases, doors and cabinetry. The male part of the joint, the tenon, is easily made on the table saw. First, the shoulders of the tenon are cut using a miter gauge to guide the workpiece. Depending on the required dimensions of your tenon, you may be able to make all four shoulder cuts without changing the saw setup. Traditionally a tenon is half the thickness of the workpiece. With a 3/4"-thick piece of wood that would require a 3/8"-thick tenon. This leaves a W shoulder on the Defining 3/i6" shoulders on all four sides of a tenon is simple. The piece is run over the blade using a miter gauge. I've added sandpaper to the face of the miter gauge to keep the piece from slipping. I'm also using a step-off block that allows me to set my fence to align the cut, but as the miter gauge moves forward, the block stays behind to avoid kickback if the piece binds. two wide sides of the tenon and that's usually a perfectly good size for the two narrow shoulders as well. With the shoulders defined it's time to cut the cheeks. There are a few ways this can be tackled on a table saw, primarily either with the piece held vertically or horizontally. To cut the cheeks horizontally, a dado cutter works well and will accurately center the tenon. Another advantage to using this accessory is that you can cut both a shoulder and a cheek in one pass. If you don't own a dado cut- Mortise-and-tenon joint Compound Miter Chart for the Table Saw

Note: The slope is measured from horizontal, with the assembly resting on a bench or work surface. Note: The slope is measured from horizontal, with the assembly resting on a bench or work surface. popwood.com 53 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||