Popular Woodworking 2005-11 № 151, страница 81

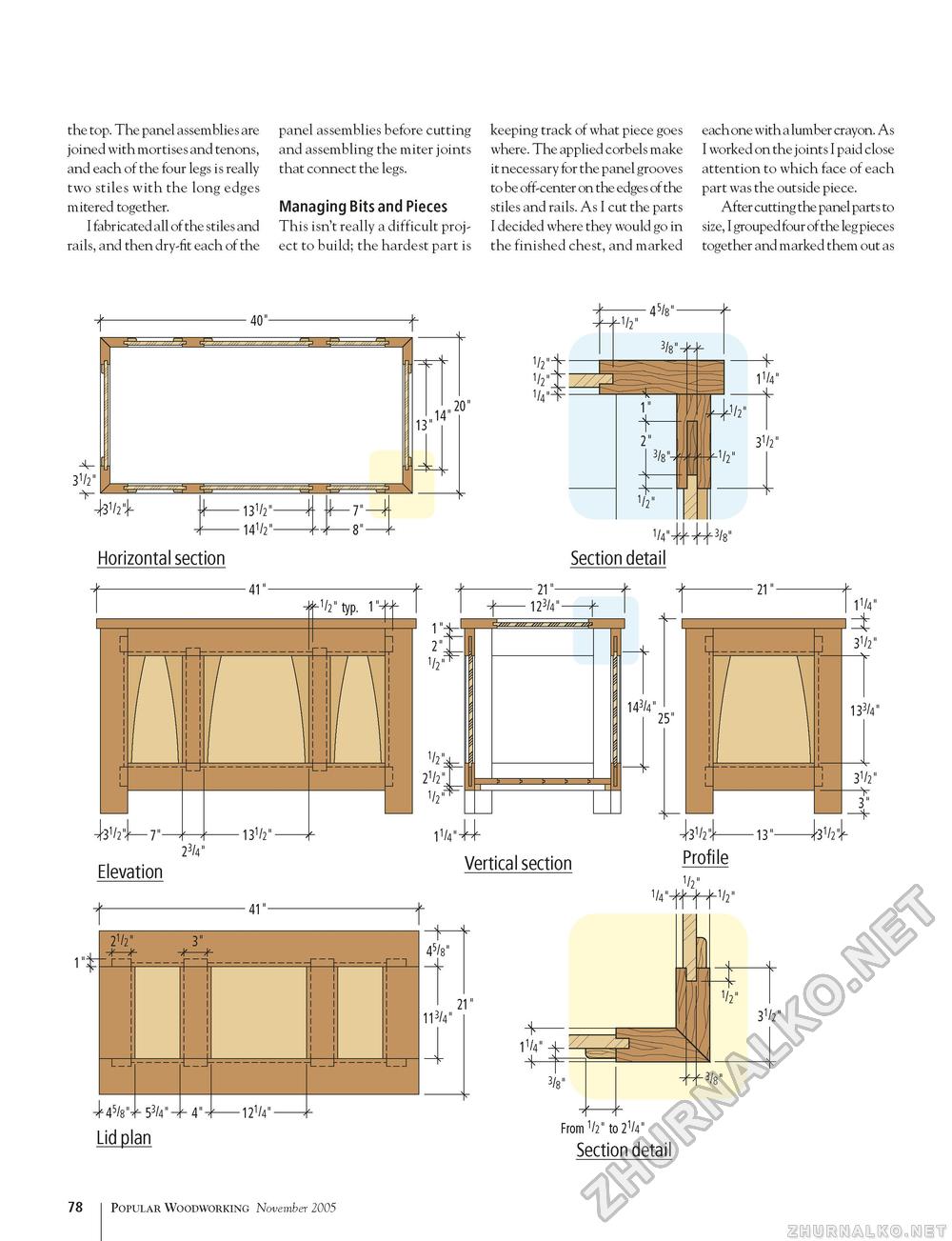

the top. The panel assemblies are joined with mortises and tenons, and each of the four legs is really two stiles with the long edges mitered together. I fabricated all of the stiles and rails, and then dry-fit each of the panel assemblies before cutting and assembling the miter joints that connect the legs. Managing Bits and Pieces This isn't really a difficult project to build; the hardest part is keeping track of what piece goes where. The applied corbels make it necessary for the panel grooves to be off-center on the edges of the stiles and rails. As I cut the parts I decided where they would go in the finished chest, and marked each one with a lumber crayon. As I worked on the joints I paid close attention to which face of each part was the outside piece. After cutting the panel parts to size, I grouped four ofthe leg pieces together and marked them out as ■ 40"- 31/2" 13" 14 20" if-13V-1 -14V2"- 7" Horizontal section Section detail 2V2" 3" i't~r"Ti-----if "IT 53/4"-M"4—12V4 Lid plan From V to 2V Section detail 78 Popular Woodworking November 2005 |