Popular Woodworking 2006-04 № 154, страница 43

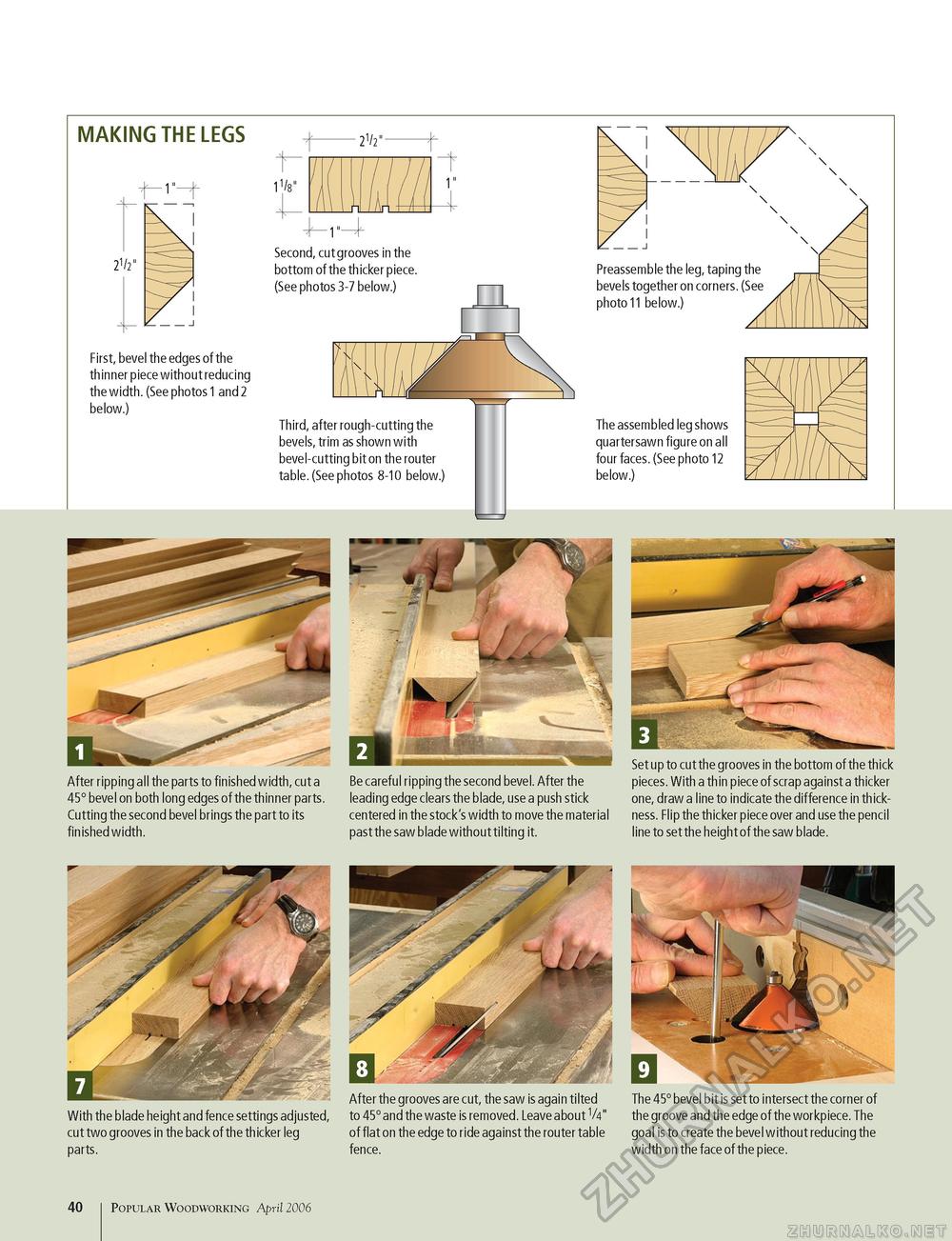

MAKING THE LEGS First, bevel the edges of the thinner piece without reducing the width. (See photos 1 and 2 below.) Second, cut grooves in the bottom of the thicker piece (See photos 3-7 below.) Third, after rough-cutting the bevels, trim as shown with bevel-cutting bit on the router table. (See photos 8-10 below.) Preassemble the leg, taping the bevels together on corners. (See photo 11 below.) The assembled leg shows quartersawn figure on all four faces. (See photo 12 below.) After ripping all the parts to finished width, cut a 45° bevel on both long edges of the thinner parts. Cutting the second bevel brings the part to its fi nished width. With the blade height and fence settings adjusted, cut two grooves in the back of the th icker leg parts. Be careful ripping the second bevel. After the leading edge clears the blade, use a push stick centered in the stock's width to move the material past the saw blade without tilting it. After the grooves are cut, the saw is again tilted to 45° and the waste is removed. Leave about V4" of flat on the edge to ride against the router table fence. Set up to cut the grooves in the bottom of the thick pieces. With a thin piece of scrap against a thicker one, draw a line to indicate the difference in thickness. Flip the thicker piece over and use the pencil line to set the height of the saw blade. The 45° bevel bit is set to intersect the corner of the groove and the edge of the workpiece. The goal is to create the bevel without reducing the width on the face of the piece. 40 Popular Woodworking April 2006 |