Popular Woodworking 2006-04 № 154, страница 77

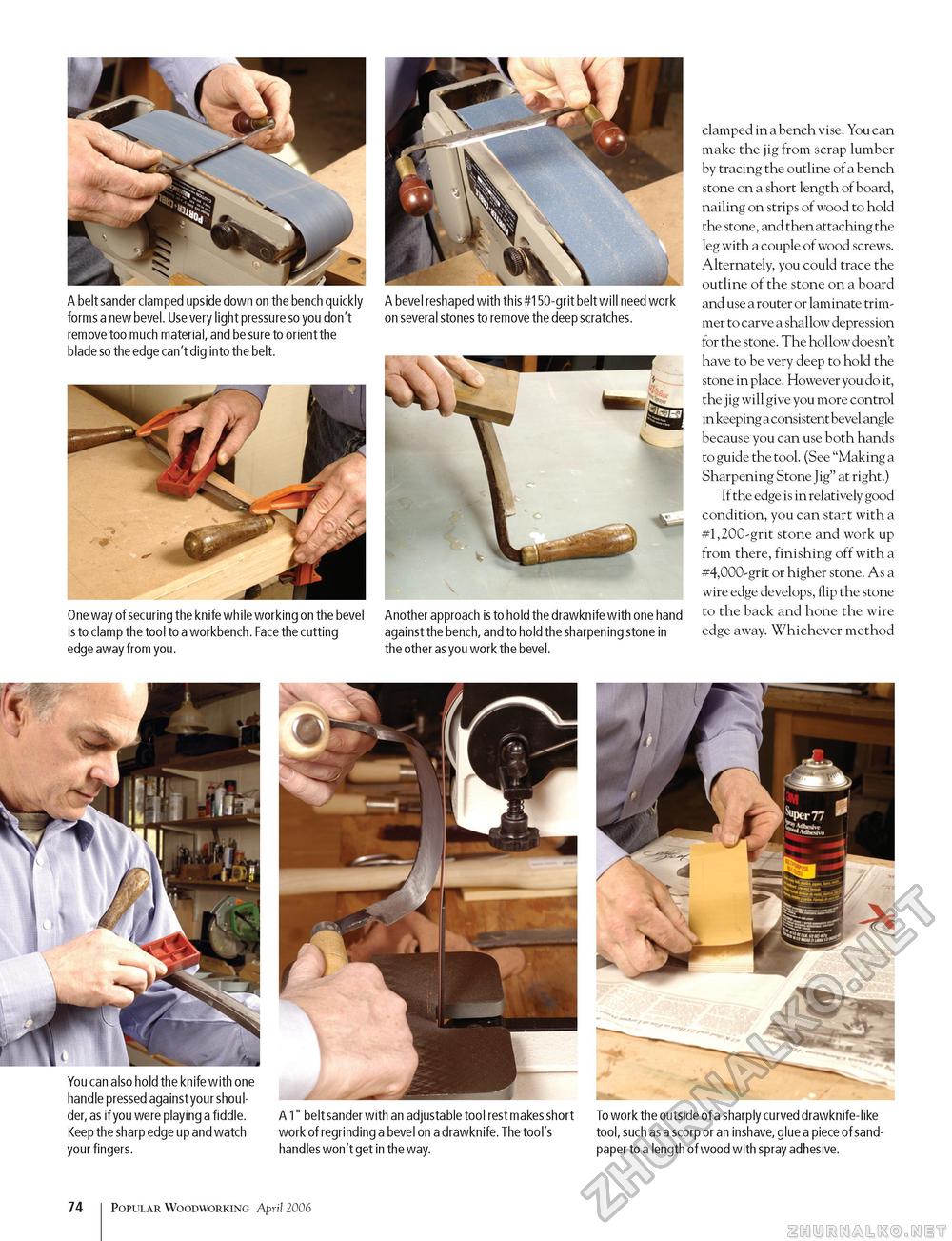

A belt sander clamped upside down on the bench quickly forms a new bevel. Use very light pressure so you don't remove too much material, and be sure to orient the blade so the edge can't dig into the belt. A bevel reshaped with this #150-grit belt will need work on several stones to remove the deep scratches. One way of securing the knife while working on the bevel is to clamp the tool to a workbench. Face the cutting edge away from you. Another approach is to hold the drawknife with one hand against the bench, and to hold the sharpening stone in the other as you work the bevel. clamped in a bench vise. You can make the jig from scrap lumber by tracing the outline of a bench stone on a short length of board, nailing on strips of wood to hold the stone, and then attaching the leg with a couple of wood screws. Alternately, you could trace the outline of the stone on a board and use a router or laminate trimmer to carve a shallow depression for the stone. The hollow doesn't have to be very deep to hold the stone in place. However you do it, the jig will give you more control in keeping a consistent bevel angle because you can use both hands to guide the tool. (See "Making a Sharpening Stone Jig" at right.) If the edge is in relatively good condition, you can start with a #1,200-grit stone and work up from there, finishing off with a #4,000-grit or higher stone. As a wire edge develops, flip the stone to the back and hone the wire edge away. Whichever method You can also hold the knife with one handle pressed against your shoulder, as if you were playing a fiddle. Keep the sharp edge up and watch your fingers. A 1" belt sander with an adjustable tool rest makes short work of regrinding a bevel on a drawknife. The tool's handles won't get in the way. To work the outside of a sharply curved drawknife-like tool, such as a scorp or an inshave, glue a piece of sandpaper to a length of wood with spray adhesive. 74 Popular Woodworking April 2006 |