Popular Woodworking 2006-06 № 155, страница 25

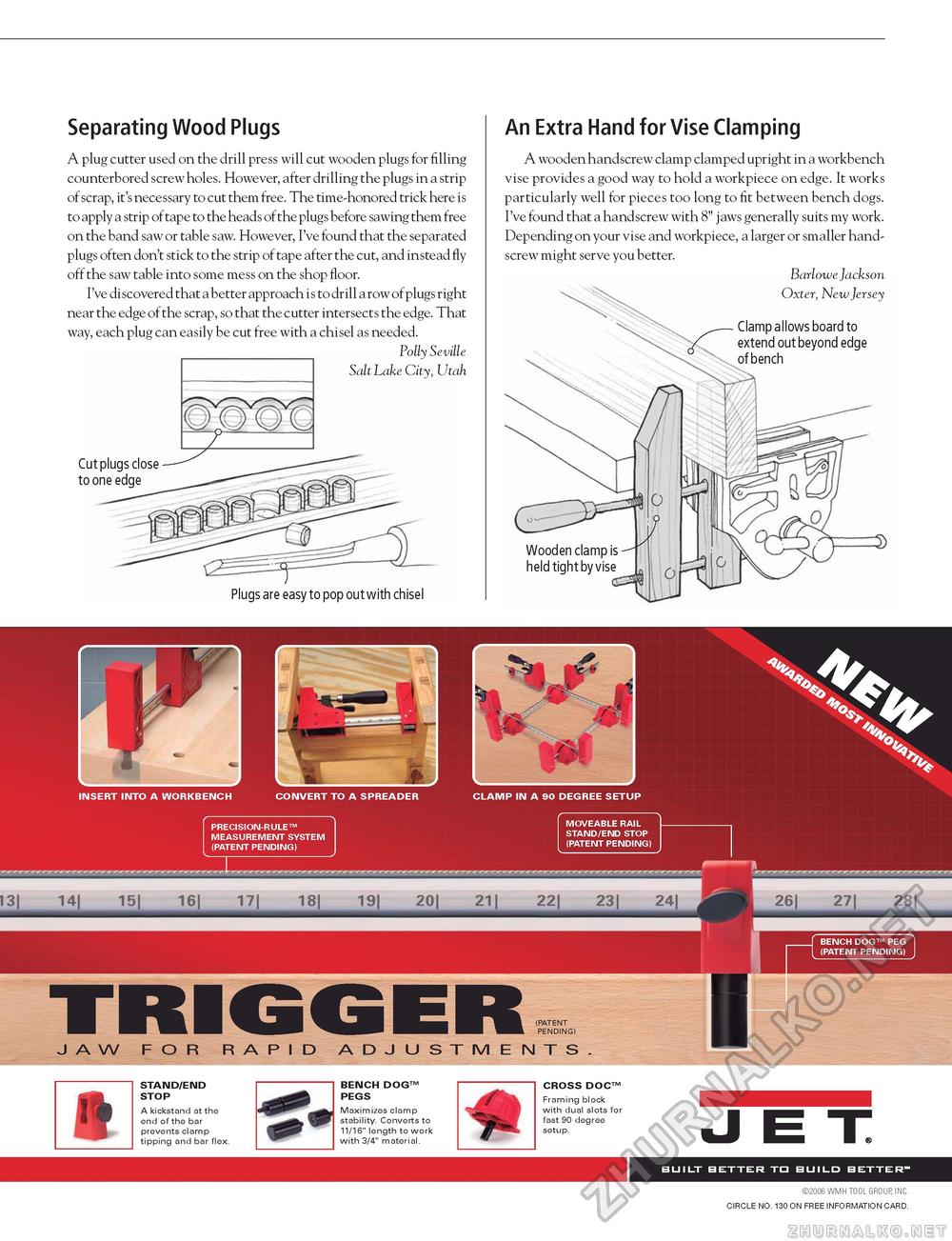

Separating Wood Plugs A plug cutter used on the drill press will cut wooden plugs for filling counterbored screw holes. However, after drilling the plugs in a strip of scrap, it's necessary to cut them free. The time-honored trick here is to apply a strip of tape to the heads of the plugs before sawing them free on the band saw or table saw. However, I've found that the separated plugs often don't stick to the strip of tape after the cut, and instead fly off the saw table into some mess on the shop floor. I've discovered that a better approach is to drill a row of plugs right near the edge of the scrap, so that the cutter intersects the edge. That way, each plug can easily be cut free with a chisel as needed. Polly Seville Salt Lake City, Utah Cut plugs close to one edge Plugs are easy to pop out with chisel An Extra Hand for Vise Clamping A wooden handscrew clamp clamped upright in a workbench vise provides a good way to hold a workpiece on edge. It works particularly well for pieces too long to fit between bench dogs. I've found that a handscrew with 8" jaws generally suits my work. Depending on your vise and workpiece, a larger or smaller hand-screw might serve you better. Barlowe Jackson Oxter, New Jersey Clamp allows board to extend out beyond edge of bench Wooden clamp is held tight by vise CONVERT TO A SPREADER PRECISION-RULE™ MEASUREMENT SYSTEM (PATENT PENDING) CLAMP IN A 90 DEGREE SETUP MOVEABLE RAIL STAND/END STOP (PATENT PENDING) MOVEABLE RAIL STAND/END STOP (PATENT PENDING)

26j 27[ 281 JAW FOR RAPID ADJUSTMENTS. STAND/END STOP A kickstand at the end of the bar prevents clamp tipping and bar flex. BENCH DOG™ PEGS Maximizes clamp stability. Convertsto 11/16" length to work with 3/4" material. CROSS DOC™ Framing block with dual slots for fast 90 degree setup. J E IL.T BETTER TO I l_D BETTER- ©2006 WMH TOOL GROUP, INC circle no. 130 on free information card. |

||||||||||||||||||||||