Popular Woodworking 2006-06 № 155, страница 67

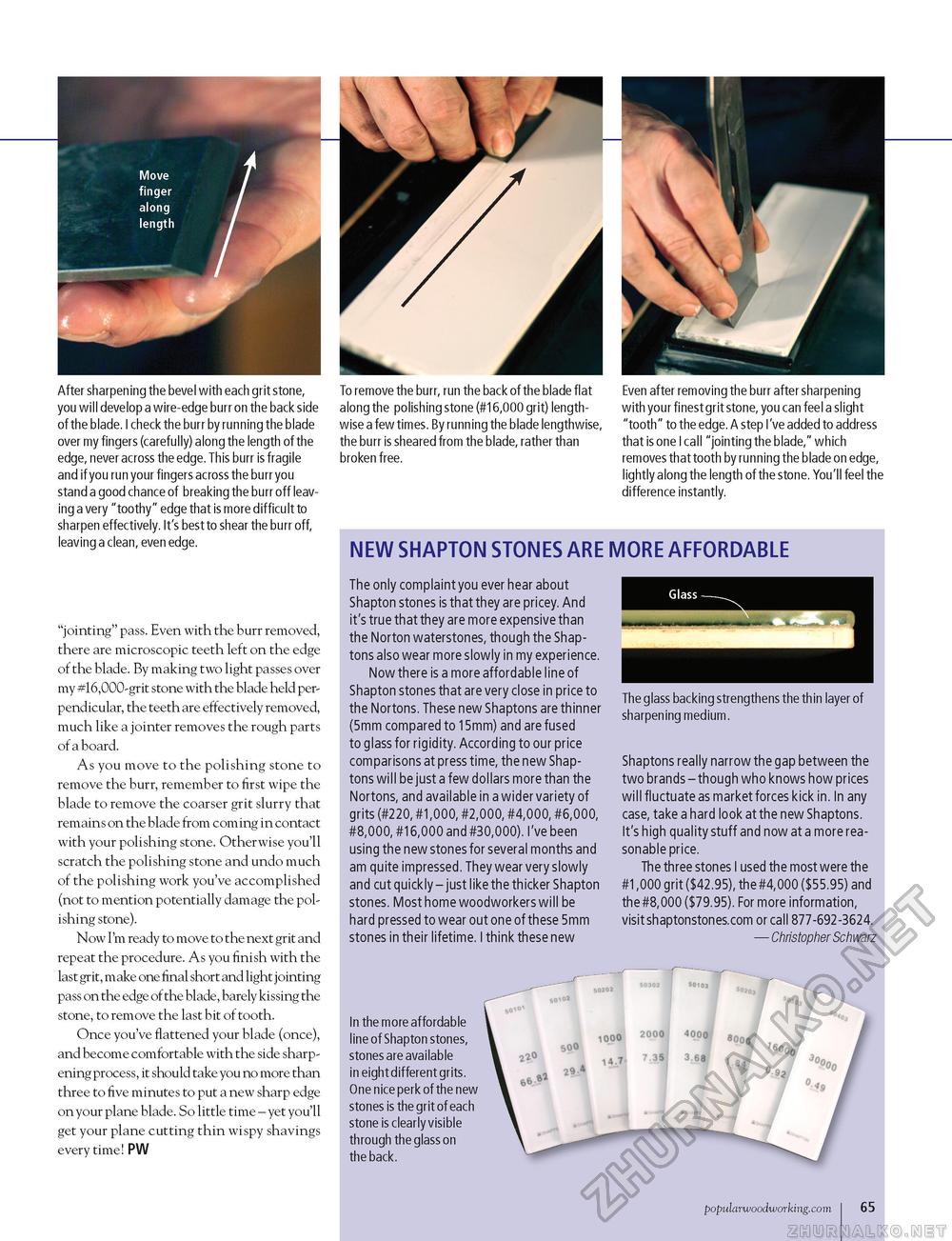

After sharpening the bevel with each grit stone, you will develop a wire-edge burr on the back side of the blade. I check the burr by running the blade over my fingers (carefully) along the length of the edge, never across the edge. This burr is fragile and if you run your fingers across the burr you stand a good chance of breaking the burr off leaving a very "toothy" edge that is more difficult to sharpen effectively. It's best to shear the burr off, leaving a clean, even edge. "jointing" pass. Even with the burr removed, there are microscopic teeth left on the edge of the blade. By making two light passes over my #16,000-grit stone with the blade held perpendicular, the teeth are effectively removed, much like a jointer removes the rough parts of a board. As you move to the polishing stone to remove the burr, remember to first wipe the blade to remove the coarser grit slurry that remains on the blade from coming in contact with your polishing stone. Otherwise you'll scratch the polishing stone and undo much of the polishing work you've accomplished (not to mention potentially damage the polishing stone). Now I'm ready to move to the next grit and repeat the procedure. As you finish with the last grit, make one final short and light jointing pass on the edge of the blade, barely kissing the stone, to remove the last bit of tooth. Once you've flattened your blade (once), and become comfortable with the side sharpening process, it should take you no more than three to five minutes to put a new sharp edge on your plane blade. So little time - yet you'll get your plane cutting thin wispy shavings every time! PW To remove the burr, run the back of the blade flat along the polishing stone (#16,000 grit) lengthwise a few times. By running the blade lengthwise, the burr is sheared from the blade, rather than broken free. The only complaint you ever hear about Shapton stones is that they are pricey. And it's true that they are more expensive than the Norton waterstones, though the Shap-tons also wear more slowly in my experience. Now there is a more affordable line of Shapton stones that are very close in price to the Nortons. These new Shaptons are thinner (5mm compared to 15mm) and are fused to glass for rigidity. According to our price comparisons at press time, the new Shaptons will be just a few dollars more than the Nortons, and available in a wider variety of grits (#220, #1,000, #2,000, #4,000, #6,000, #8,000, #16,000 and #30,000). I've been using the new stones for several months and am quite impressed. They wear very slowly and cut quickly - just like the thicker Shapton stones. Most home woodworkers will be hard pressed to wear out one of these 5mm stones in their lifetime. I think these new Even after removing the burr after sharpening with your finest grit stone, you can feel a slight "tooth" to the edge. A step I've added to address that is one I call "jointing the blade," which removes that tooth by running the blade on edge, lightly along the length of the stone. You'll feel the difference instantly. The glass backing strengthens the thin layer of sharpening medium. Shaptons really narrow the gap between the two brands - though who knows how prices will fluctuate as market forces kick in. In any case, take a hard look at the new Shaptons. It's high quality stuff and now at a more reasonable price. The three stones I used the most were the #1,000 grit ($42.95), the #4,000 ($55.95) and the #8,000 ($79.95). For more information, visit shaptonstones.com or call 877-692-3624. — Christopher Schwarz In the more affordable line of Shapton stones, stones are available in eight different grits. One nice perk of the new stones is the grit of each stone is clearly visible through the glass on the back. NEW SHAPTON STONES ARE MORE AFFORDABLE popularwoodworking.com I 65 |