Popular Woodworking 2006-12 № 159, страница 59

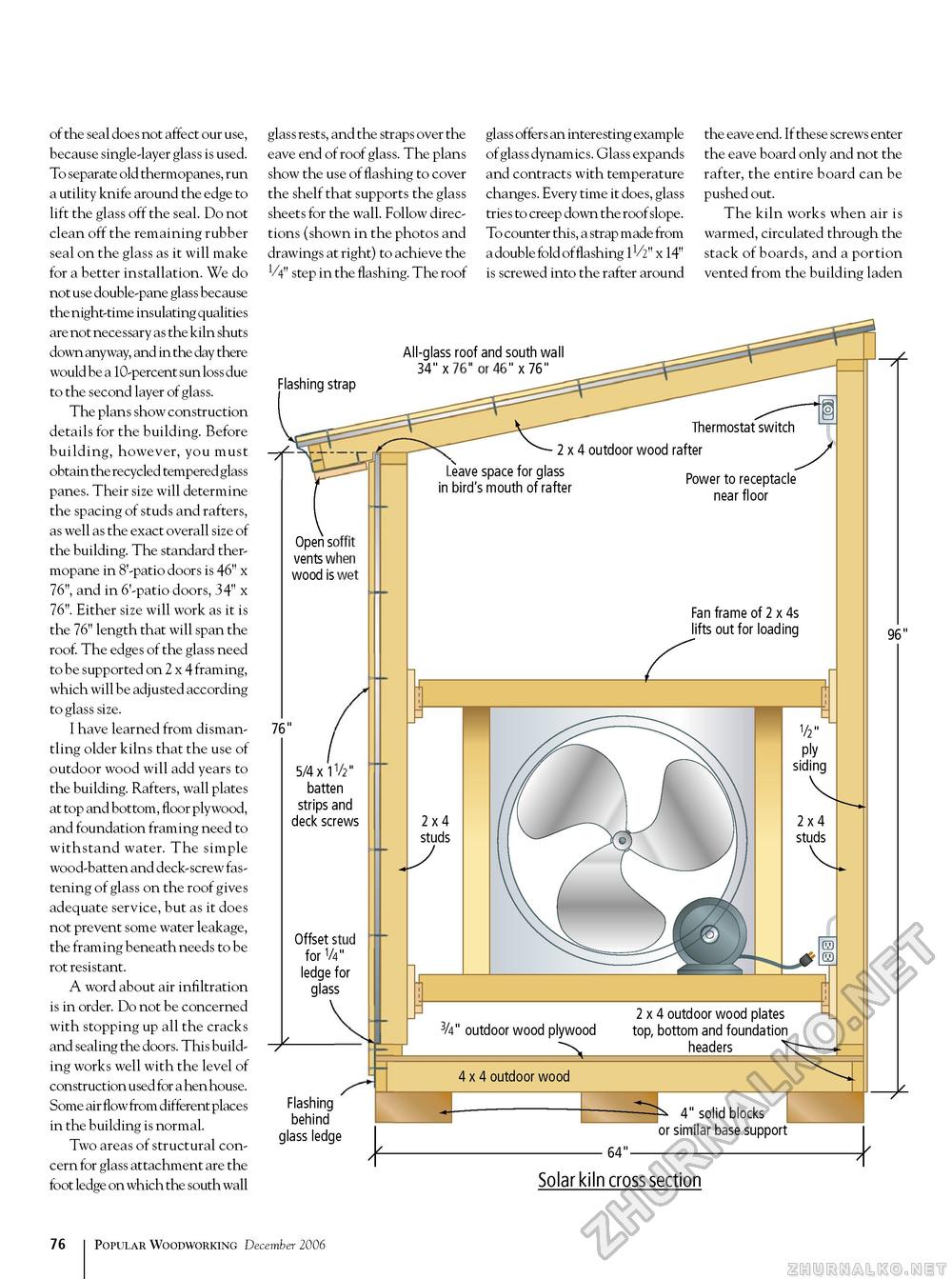

of the seal does not affect our use, because single-layer glass is used. To separate old thermopanes, run a utility knife around the edge to lift the glass off the seal. Do not clean off the remaining rubber seal on the glass as it will make for a better installation. We do not use double-pane glass because the night-time insulating qualities are not necessary as the kiln shuts down anyway, and in the day there would be a 10-percent sun loss due to the second layer of glass. The plans show construction details for the building. Before building, however, you must obtain the recycled tempered glass panes. Their size will determine the spacing of studs and rafters, as well as the exact overall size of the building. The standard ther-mopane in 8'-patio doors is 46" x 76", and in 6'-patio doors, 34" x 76". Either size will work as it is the 76" length that will span the roof. The edges of the glass need to be supported on 2 x 4 framing, which will be adjusted according to glass size. I have learned from dismantling older kilns that the use of outdoor wood will add years to the building. Rafters, wall plates at top and bottom, floor plywood, and foundation framing need to withstand water. The simple wood-batten and deck-screw fastening of glass on the roof gives adequate service, but as it does not prevent some water leakage, the framing beneath needs to be rot resistant. A word about air infiltration is in order. Do not be concerned with stopping up all the cracks and sealing the doors. This building works well with the level of construction used for a hen house. Some air flow from different places in the building is normal. Two areas of structural concern for glass attachment are the foot ledge on which the south wall glass rests, and the straps over the eave end of roof glass. The plans show the use of flashing to cover the shelf that supports the glass sheets for the wall. Follow directions (shown in the photos and drawings at right) to achieve the step in the flashing. The roof glass offers an interesting example of glass dynamics. Glass expands and contracts with temperature changes. Every time it does, glass tries to creep down the roof slope. To counter this, a strap made from a double fold offlashing 11/2" x 14" is screwed into the rafter around the eave end. If these screws enter the eave board only and not the rafter, the entire board can be pushed out. The kiln works when air is warmed, circulated through the stack of boards, and a portion vented from the building laden Flashing All-glass roof and south wall 34" x76" or 46" x76" Open soffit vents when wood is wet 76" 5/4x1 Vi" batten strips and deck screws Offset stud for V4" ledge for glass Thermostat switch •2 x 4 outdoor wood rafter Leave space for glass in bird's mouth of rafter Power to receptacle near floor Fan frame of 2 x 4s lifts out for loading Flashing behind glass ledge 96" 3/4" outdoor wood plywood 2 x 4 outdoor wood plates top, bottom and foundation headers 4 x 4 outdoor wood 4" solid blocks or similar base support 64"- Solar kiln cross section 76 Popular Woodworking December 2006 |