Popular Woodworking 2006-12 № 159, страница 60

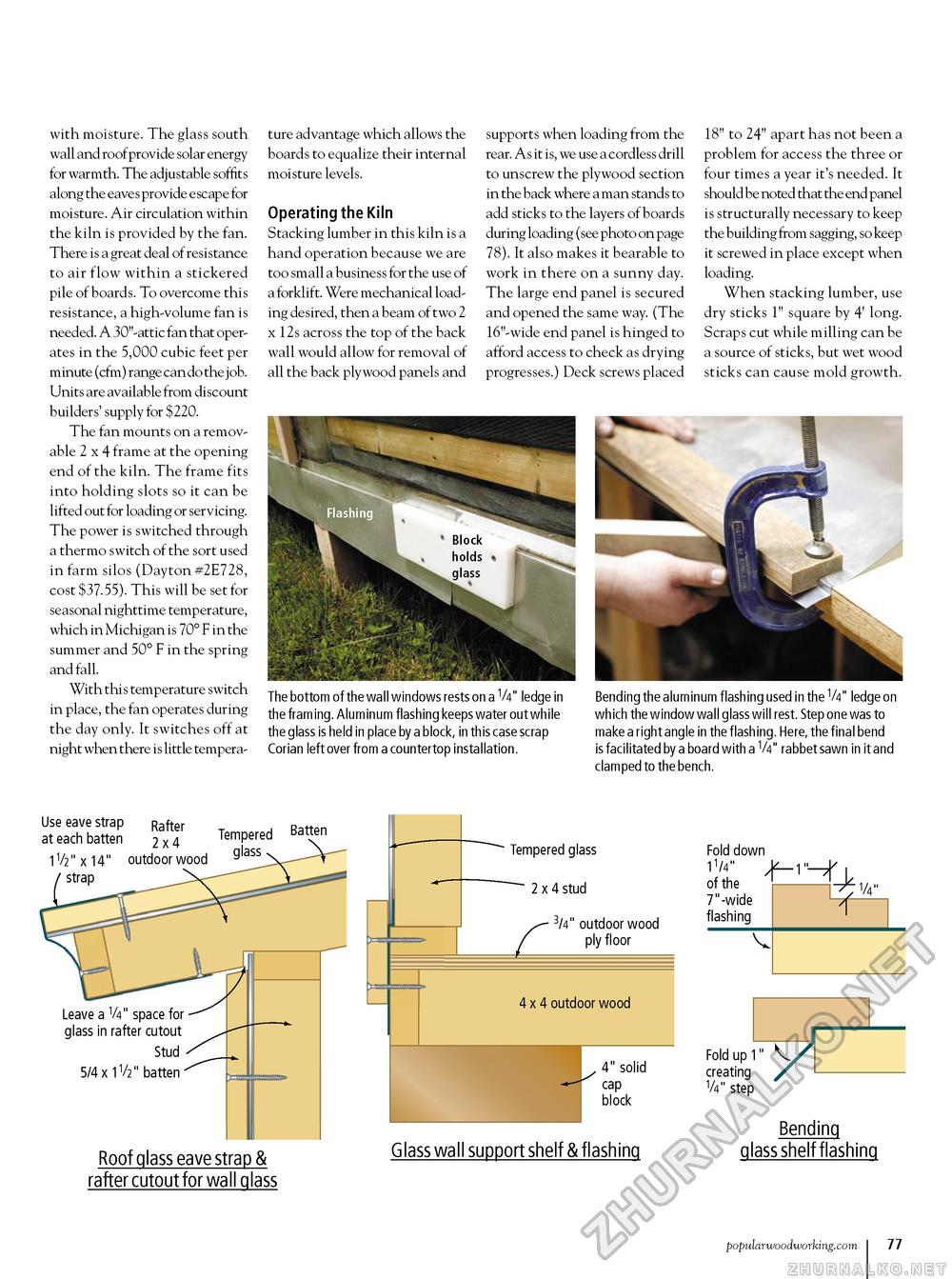

with moisture. The glass south wall and roof provide solar energy for warmth. The adjustable soffits along the eaves provide escape for moisture. Air circulation within the kiln is provided by the fan. There is a great deal of resistance to air flow within a stickered pile of boards. To overcome this resistance, a high-volume fan is needed. A 30"-attic fan that operates in the 5,000 cubic feet per minute (cfm) range can do the job. Units are available from discount builders' supply for $220. The fan mounts on a removable 2 x 4 frame at the opening end of the kiln. The frame fits into holding slots so it can be lifted out for loading or servicing. The power is switched through a thermo switch of the sort used in farm silos (Dayton #2E728, cost $37.55). This will be set for seasonal nighttime temperature, which in Michigan is 70° F in the summer and 50° F in the spring and fall. With this temperature switch in place, the fan operates during the day only. It switches off at night when there is little tempera ture advantage which allows the boards to equalize their internal moisture levels. Operating the Kiln Stacking lumber in this kiln is a hand operation because we are too small a business for the use of a forklift. Were mechanical loading desired, then a beam of two 2 x 12s across the top of the back wall would allow for removal of all the back plywood panels and supports when loading from the rear. As it is, we use a cordless drill to unscrew the plywood section in the back where a man stands to add sticks to the layers of boards during loading (see photo on page 78). It also makes it bearable to work in there on a sunny day. The large end panel is secured and opened the same way. (The 16"-wide end panel is hinged to afford access to check as drying progresses.) Deck screws placed 18" to 24" apart has not been a problem for access the three or four times a year it's needed. It should be noted that the end panel is structurally necessary to keep the building from sagging, so keep it screwed in place except when loading. When stacking lumber, use dry sticks 1" square by 4' long. Scraps cut while milling can be a source of sticks, but wet wood sticks can cause mold growth. The bottom of the wall windows rests on a V4" ledge in the framing. Aluminum flashing keeps water out while the glass is held in place by a block, in this case scrap Corian left over from a countertop installation. Bending the aluminum flashing used in the V4" ledge on which the window wall glass will rest. Step one was to make a right angle in the flashing. Here, the final bend is facilitated by a board with a V4" rabbet sawn in it and clamped to the bench. Use eave strap at each batten 1V2" x 14" strap Rafter 2 x 4 outdoor wood Tempered glass Tempered glass 2 x 4 stud Leave a V4" space for glass in rafter cutout Stud 5/4 x 1V2" batten Roof glass eave strap & rafter cutout for wall glass cap block Glass wall support shelf & flashing Fold down 11/4" , of the 7"-wide flashing V4" V Fold up 1" creating V4" step 7t Bending glass shelf flashing popularwoodworking.com i 77 |