Popular Woodworking 2006-12 № 159, страница 61

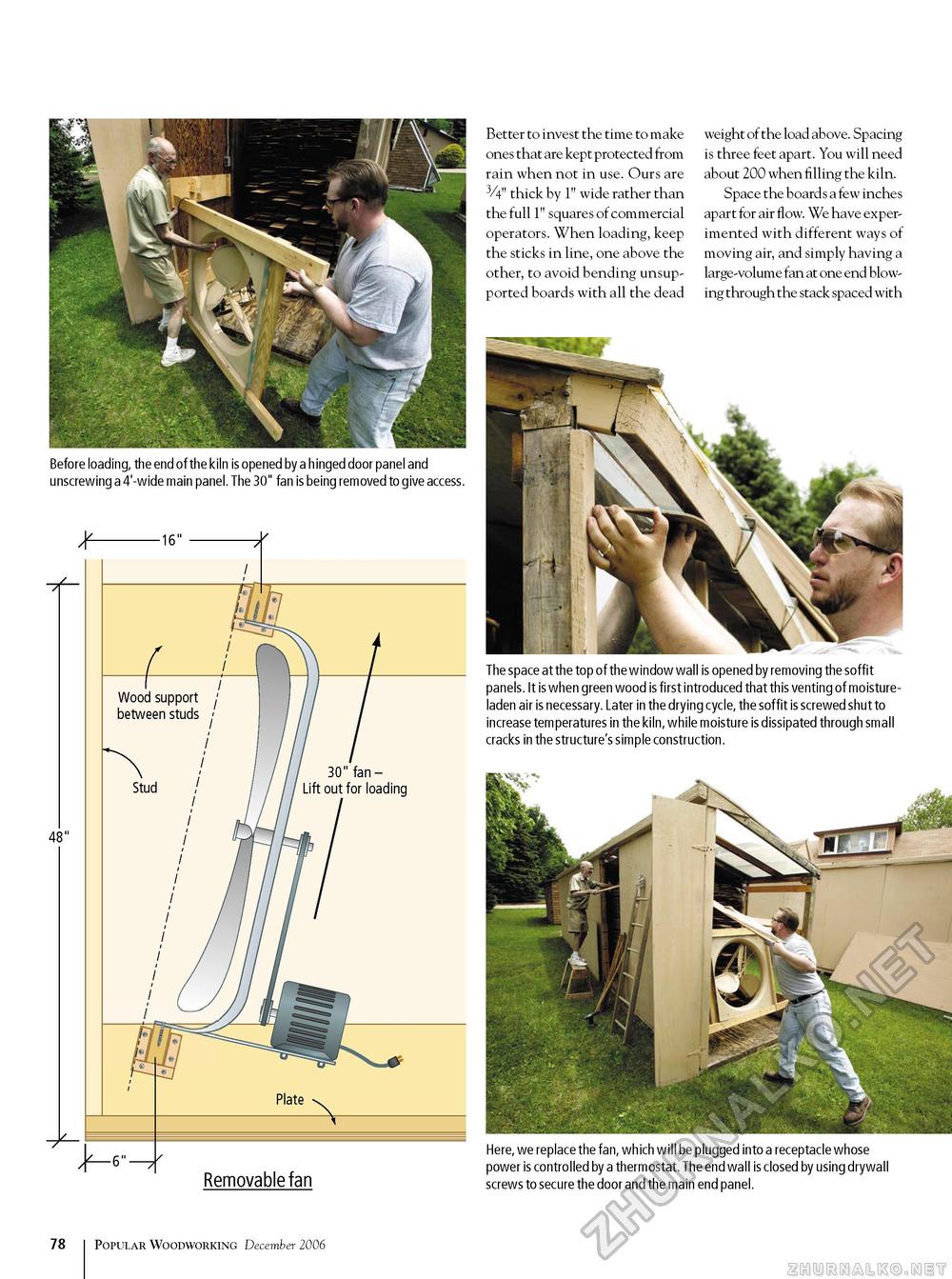

Before loading, the end of the kiln is opened by a hinged door panel and unscrewing a 4'-wide main panel. The 30" fan is being removed to give access. Better to invest the time to make ones that are kept protected from rain when not in use. Ours are 3/4" thick by 1" wide rather than the full 1" squares of commercial operators. When loading, keep the sticks in line, one above the other, to avoid bending unsupported boards with all the dead weight of the load above. Spacing is three feet apart. You will need about 200 when filling the kiln. Space the boards a few inches apart for air flow. We have experimented with different ways of moving air, and simply having a large-volume fan at one end blowing through the stack spaced with The space at the top of the window wall is opened by removing the soffit panels. It is when green wood is first introduced that this venting of moisture-laden air is necessary. Later in the drying cycle, the soffit is screwed shut to increase temperatures in the kiln, while moisture is dissipated through small cracks in the structure's simple construction. Removable fan Here, we replace the fan, which will be plugged into a receptacle whose power is controlled by a thermostat. The end wall is closed by using drywall screws to secure the door and the main end panel. 78 Popular Woodworking December 2006 |