Popular Woodworking 2006-12 № 159, страница 69

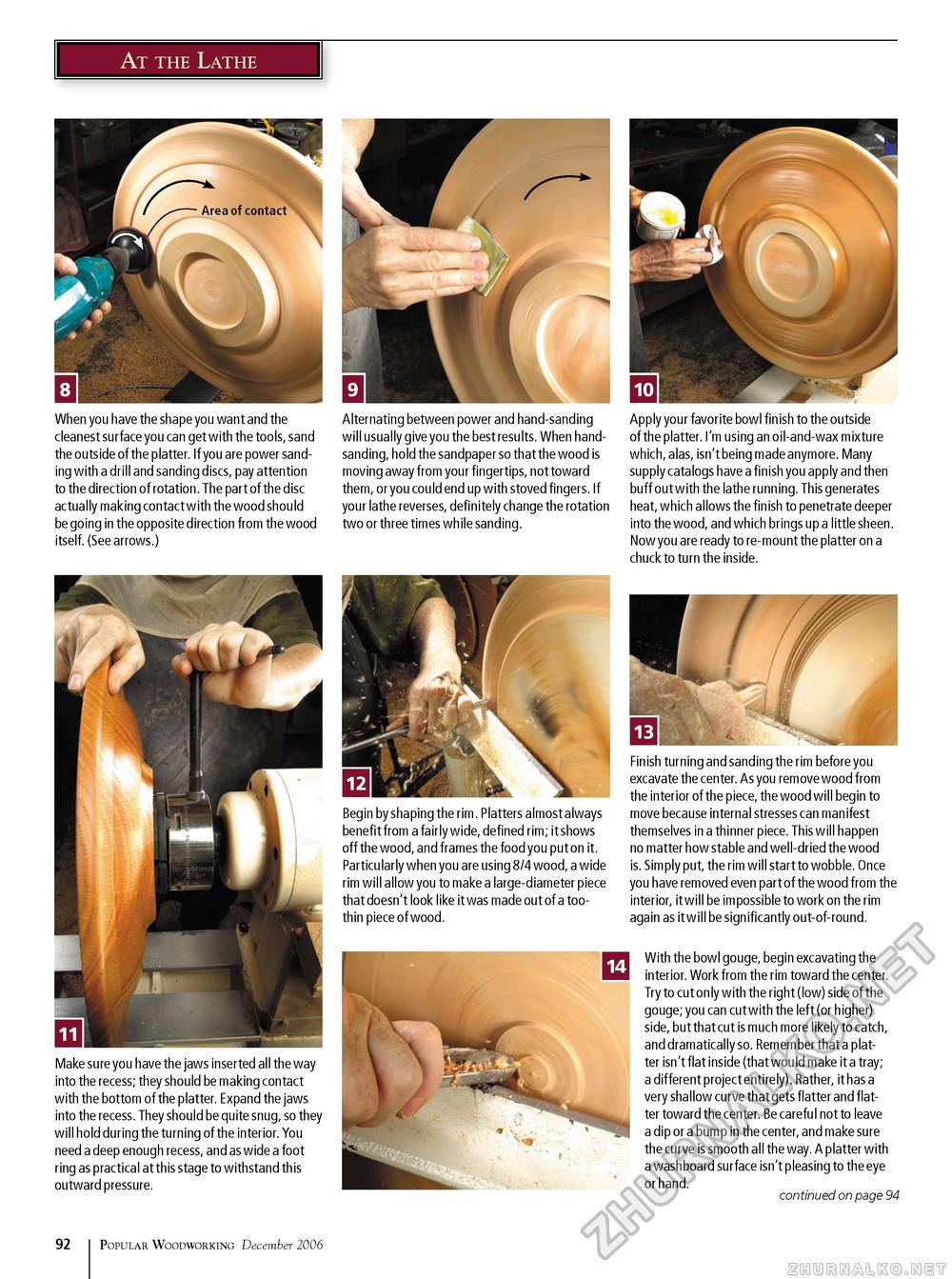

At the Lathe When you have the shape you want and the cleanest surface you can get with the tools, sand the outside of the platter. If you are power sanding with a drill and sanding discs, pay attention to the direction of rotation. The part of the disc actually making contact with the wood should be going in the opposite direction from the wood itself. (See arrows.) Alternating between power and hand-sanding will usually give you the best results. When hand-sanding, hold the sandpaper so that the wood is moving away from your fingertips, not toward them, or you could end up with stoved fingers. If your lathe reverses, definitely change the rotation two or three times while sanding. Apply your favorite bowl finish to the outside of the platter. I'm using an oil-and-wax mixture which, alas, isn't being made anymore. Many supply catalogs have a finish you apply and then buff out with the lathe running. This generates heat, which allows the finish to penetrate deeper into the wood, and which brings up a little sheen. Now you are ready to re-mount the platter on a chuck to turn the inside. 0- M ' * "S - \ i2 Begin by shaping the rim. Platters almost always benefit from a fairly wide, defined rim; it shows off the wood, and frames the food you put on it. Particularly when you are using 8/4 wood, a wide rim will allow you to make a large-diameter piece that doesn't look like it was made out of a too-thin piece of wood. Make sure you have the jaws inserted all the way into the recess; they should be making contact with the bottom of the platter. Expand the jaws into the recess. They should be quite snug, so they will hold during the turning of the interior. You need a deep enough recess, and as wide a foot ring as practical at this stage to withstand this outward pressure. Finish turning and sanding the rim before you excavate the center. As you remove wood from the interior of the piece, the wood will begin to move because internal stresses can manifest themselves in a thinner piece. This will happen no matter how stable and well-dried the wood is. Simply put, the rim will start to wobble. Once you have removed even part of the wood from the interior, it will be impossible to work on the rim again as it will be significantly out-of-round. With the bowl gouge, begin excavating the interior. Work from the rim toward the center. Try to cut only with the right (low) side of the gouge; you can cut with the left (or higher) side, but that cut is much more likely to catch, and dramatically so. Remember that a platter isn't flat inside (that would make it a tray; a different project entirely). Rather, it has a very shallow curve that gets flatter and flatter toward the center. Be careful not to leave a dip or a bump in the center, and make sure the curve is smooth all the way. A platter with a washboard surface isn't pleasing to the eye or hand. continued on page 94 92 Popular Woodworking December 2006 |