Popular Woodworking 2006-12 № 159, страница 71

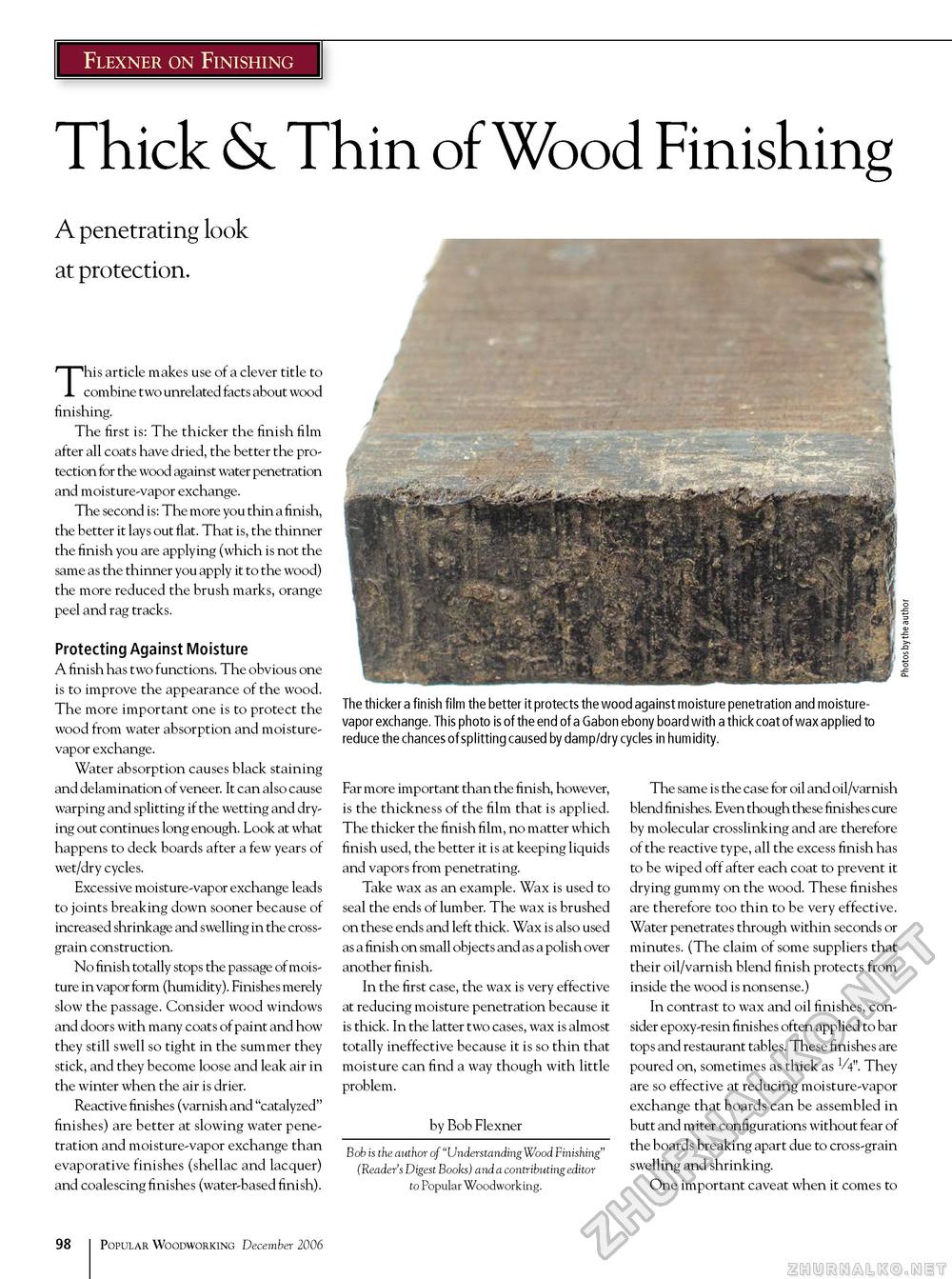

Flexner on Finishing Thick & Thin of Wood Finishing A penetrating look at protection. This article makes use of a clever title to combine two unrelated facts about wood finishing. The first is: The thicker the finish film after all coats have dried, the better the protection for the wood against water penetration and moisture-vapor exchange. The second is: The more you thin a finish, the better it lays out flat. That is, the thinner the finish you are applying (which is not the same as the thinner you apply it to the wood) the more reduced the brush marks, orange peel and rag tracks. Protecting Against Moisture A finish has two functions. The obvious one is to improve the appearance of the wood. The more important one is to protect the wood from water absorption and moisture-vapor exchange. Water absorption causes black staining and delamination of veneer. It can also cause warping and splitting if the wetting and drying out continues long enough. Look at what happens to deck boards after a few years of wet/dry cycles. Excessive moisture-vapor exchange leads to joints breaking down sooner because of increased shrinkage and swelling in the cross-grain construction. No finish totally stops the passage of moisture in vapor form (humidity). Finishes merely slow the passage. Consider wood windows and doors with many coats of paint and how they still swell so tight in the summer they stick, and they become loose and leak air in the winter when the air is drier. Reactive finishes (varnish and "catalyzed" finishes) are better at slowing water penetration and moisture-vapor exchange than evaporative finishes (shellac and lacquer) and coalescing finishes (water-based finish). The thicker a finish film the better it protects the wood against moisture penetration and moisture-vapor exchange. This photo is of the end of a Gabon ebony board with a thick coat of wax applied to reduce the chances of splitting caused by damp/dry cycles in humidity. Far more important than the finish, however, is the thickness of the film that is applied. The thicker the finish film, no matter which finish used, the better it is at keeping liquids and vapors from penetrating. Take wax as an example. Wax is used to seal the ends of lumber. The wax is brushed on these ends and left thick. Wax is also used as a finish on small objects and as a polish over another finish. In the first case, the wax is very effective at reducing moisture penetration because it is thick. In the latter two cases, wax is almost totally ineffective because it is so thin that moisture can find a way though with little problem. by Bob Flexner Bob is the author of "Understanding Wood Finishing" (Reader's Digest Books) and a contributing editor to Popular Woodworking. The same is the case for oil and oil/varnish blend finishes. Even though these finishes cure by molecular crosslinking and are therefore of the reactive type, all the excess finish has to be wiped off after each coat to prevent it drying gummy on the wood. These finishes are therefore too thin to be very effective. Water penetrates through within seconds or minutes. (The claim of some suppliers that their oil/varnish blend finish protects from inside the wood is nonsense.) In contrast to wax and oil finishes, consider epoxy-resin finishes often applied to bar tops and restaurant tables. These finishes are poured on, sometimes as thick as V4". They are so effective at reducing moisture-vapor exchange that boards can be assembled in butt and miter configurations without fear of the boards breaking apart due to cross-grain swelling and shrinking. One important caveat when it comes to 98 Popular Woodworking December 2006 |