Popular Woodworking 2006-12 № 159, страница 70

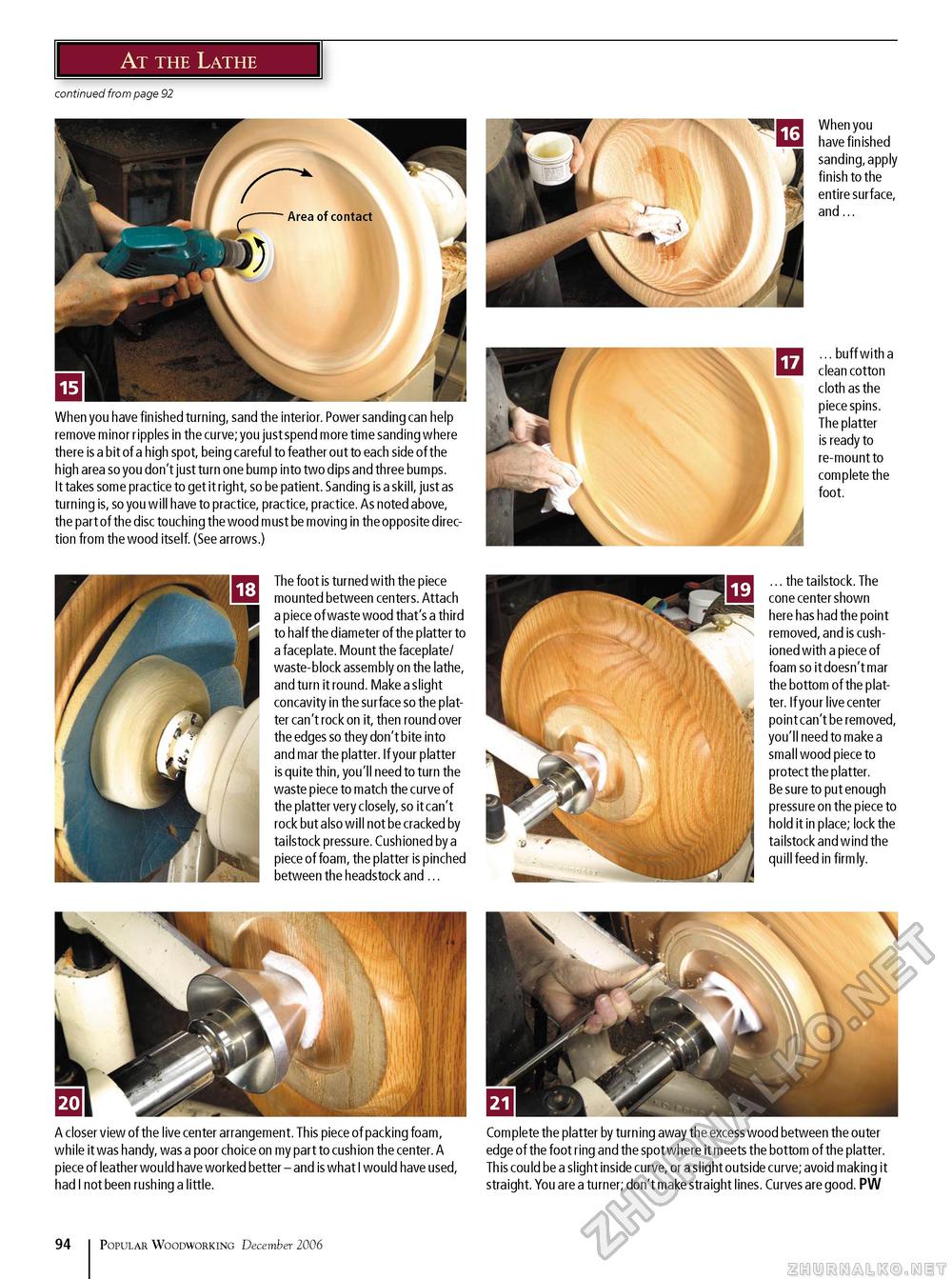

At the Lathe continued from page 92 When you have finished turning, sand the interior. Power sanding can help remove minor ripples in the curve; you just spend more time sanding where there is a bit of a high spot, being careful to feather out to each side of the high area so you don't just turn one bump into two dips and three bumps. It takes some practice to get it right, so be patient. Sanding is a skill, just as turning is, so you will have to practice, practice, practice. As noted above, the part of the disc touching the wood must be moving in the opposite direction from the wood itself. (See arrows.) The foot is turned with the piece mounted between centers. Attach a piece of waste wood that's a third to half the diameter of the platter to a faceplate. Mount the faceplate/ waste-block assembly on the lathe, and turn it round. Make a slight concavity in the surface so the platter can't rock on it, then round over the edges so they don't bite into and mar the platter. If your platter is quite thin, you'll need to turn the waste piece to match the curve of the platter very closely, so it can't rock but also will not be cracked by tailstock pressure. Cushioned by a piece of foam, the platter is pinched between the headstock and ... When you have finished sanding, apply finish to the entire surface, and . . buff with a clean cotton cloth as the piece spins. The platter is ready to re-mount to complete the foot. ... the tailstock. The cone center shown here has had the point removed, and is cushioned with a piece of foam so it doesn't mar the bottom of the platter. If your live center point can't be removed, you'll need to make a small wood piece to protect the platter. Be sure to put enough pressure on the piece to hold it in place; lock the tailstock and wind the quill feed in firmly. A closer view of the live center arrangement. This piece of packing foam, while it was handy, was a poor choice on my part to cushion the center. A piece of leather would have worked better - and is what I would have used, had I not been rushing a little. Complete the platter by turning away the excess wood between the outer edge of the foot ring and the spot where it meets the bottom of the platter. This could be a slight inside curve, or a slight outside curve; avoid making it straight. You are a turner; don't make straight lines. Curves are good. PW 94 Popular Woodworking December 2006 |