Popular Woodworking 2006-12 № 159, страница 72

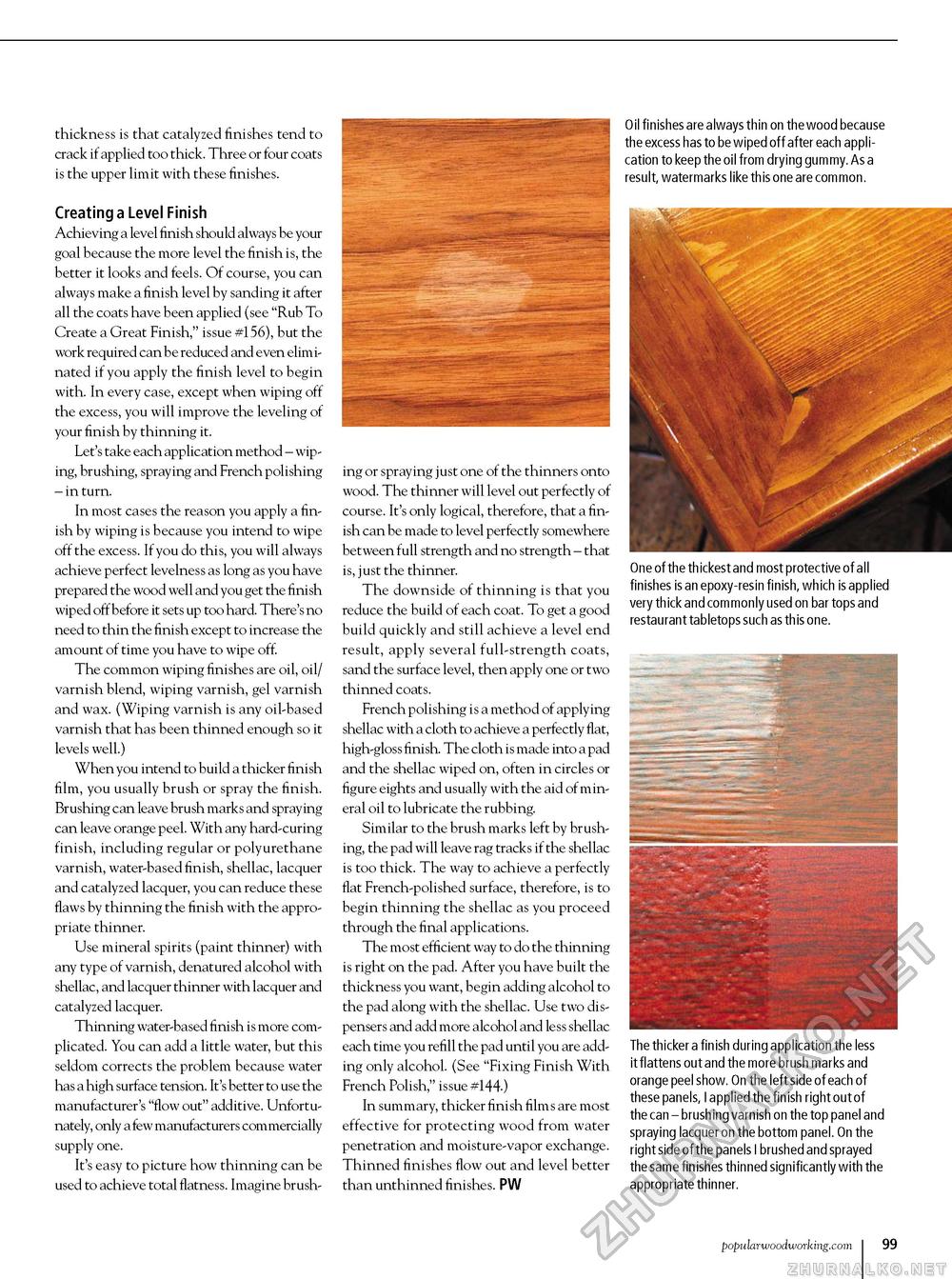

thickness is that catalyzed finishes tend to crack if applied too thick. Three or four coats is the upper limit with these finishes. Creating a Level Finish Achieving a level finish should always be your goal because the more level the finish is, the better it looks and feels. Of course, you can always make a finish level by sanding it after all the coats have been applied (see "Rub To Create a Great Finish," issue #156), but the work required can be reduced and even eliminated if you apply the finish level to begin with. In every case, except when wiping off the excess, you will improve the leveling of your finish by thinning it. Let's take each application method - wiping, brushing, spraying and French polishing - in turn. In most cases the reason you apply a finish by wiping is because you intend to wipe off the excess. If you do this, you will always achieve perfect levelness as long as you have prepared the wood well and you get the finish wiped off before it sets up too hard. There's no need to thin the finish except to increase the amount of time you have to wipe off. The common wiping finishes are oil, oil/ varnish blend, wiping varnish, gel varnish and wax. (Wiping varnish is any oil-based varnish that has been thinned enough so it levels well.) When you intend to build a thicker finish film, you usually brush or spray the finish. Brushing can leave brush marks and spraying can leave orange peel. With any hard-curing finish, including regular or polyurethane varnish, water-based finish, shellac, lacquer and catalyzed lacquer, you can reduce these flaws by thinning the finish with the appropriate thinner. Use mineral spirits (paint thinner) with any type of varnish, denatured alcohol with shellac, and lacquer thinner with lacquer and catalyzed lacquer. Thinning water-based finish is more complicated. You can add a little water, but this seldom corrects the problem because water has a high surface tension. It's better to use the manufacturer's "flow out" additive. Unfortunately, only a few manufacturers commercially supply one. It's easy to picture how thinning can be used to achieve total flatness. Imagine brush Oil finishes are always thin on the wood because the excess has to be wiped off after each application to keep the oil from drying gummy. As a result, watermarks like this one are common. ing or spraying just one of the thinners onto wood. The thinner will level out perfectly of course. It's only logical, therefore, that a finish can be made to level perfectly somewhere between full strength and no strength - that is, just the thinner. The downside of thinning is that you reduce the build of each coat. To get a good build quickly and still achieve a level end result, apply several full-strength coats, sand the surface level, then apply one or two thinned coats. French polishing is a method of applying shellac with a cloth to achieve a perfectly flat, high-gloss finish. The cloth is made into a pad and the shellac wiped on, often in circles or figure eights and usually with the aid of mineral oil to lubricate the rubbing. Similar to the brush marks left by brushing, the pad will leave rag tracks if the shellac is too thick. The way to achieve a perfectly flat French-polished surface, therefore, is to begin thinning the shellac as you proceed through the final applications. The most efficient way to do the thinning is right on the pad. After you have built the thickness you want, begin adding alcohol to the pad along with the shellac. Use two dispensers and add more alcohol and less shellac each time you refill the pad until you are adding only alcohol. (See "Fixing Finish With French Polish," issue #144.) In summary, thicker finish films are most effective for protecting wood from water penetration and moisture-vapor exchange. Thinned finishes flow out and level better than unthinned finishes. PW One of the th ickest and most protective of all finishes is an epoxy-resin finish, which is applied very thick and commonly used on bar tops and restaurant tabletops such as this one. The thicker a finish during application the less it flattens out and the more brush marks and orange peel show. On the left side of each of these panels, I applied the finish right out of the can - brushing varnish on the top panel and spraying lacquer on the bottom panel. On the right side of the panels I brushed and sprayed the same finishes thinned significantly with the appropriate thinner. popularwoodworking.com i 99 |