Popular Woodworking 2007-02 № 160, страница 11

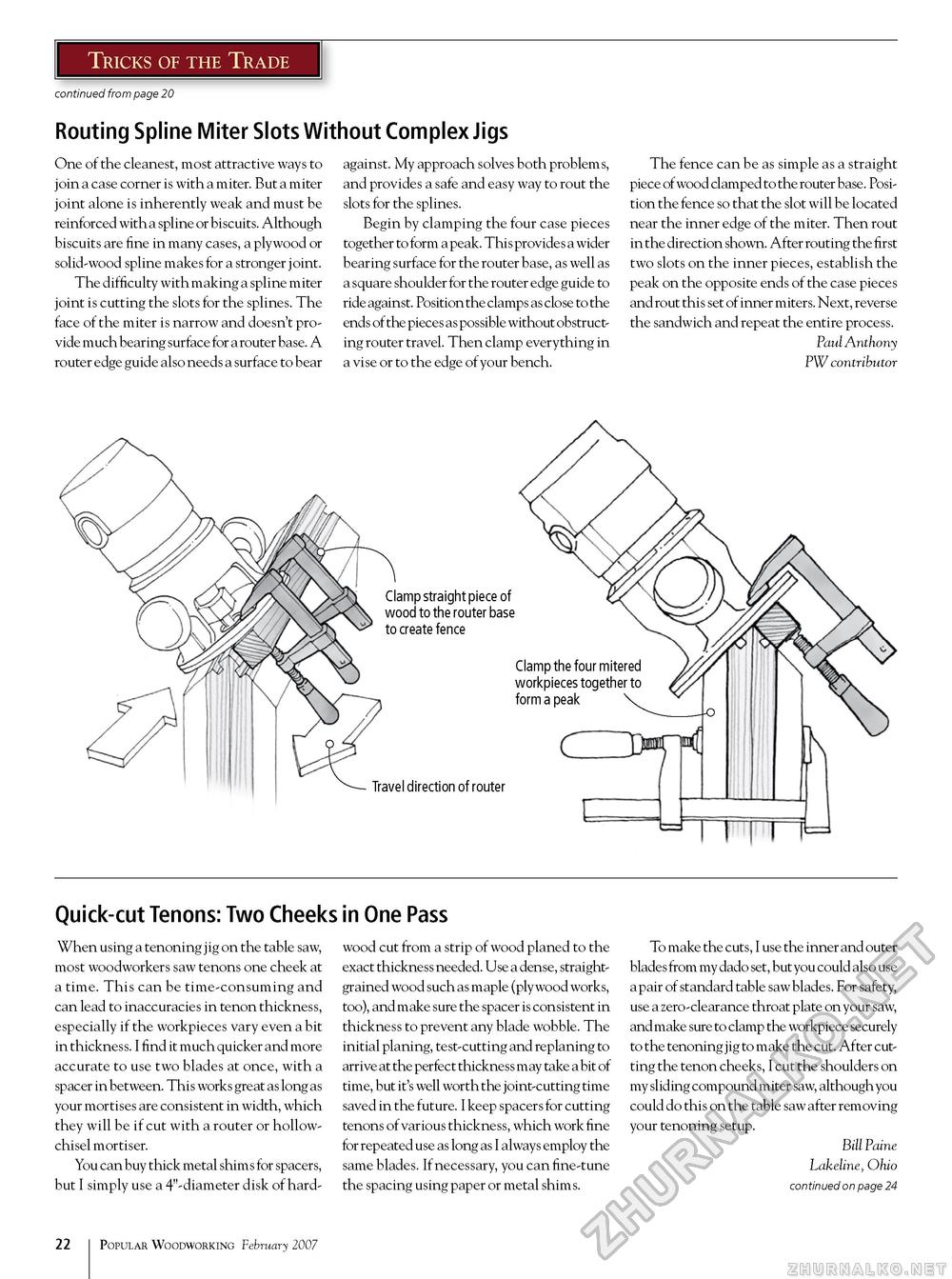

Tricks of the Trade continued from page 20 Routing Spline Miter Slots Without Complex Jigs One of the cleanest, most attractive ways to join a case corner is with a miter. But a miter joint alone is inherently weak and must be reinforced with a spline or biscuits. Although biscuits are fine in many cases, a plywood or solid-wood spline makes for a stronger joint. The difficulty with making a spline miter joint is cutting the slots for the splines. The face of the miter is narrow and doesn't provide much bearing surface for a router base. A router edge guide also needs a surface to bear against. My approach solves both problems, and provides a safe and easy way to rout the slots for the splines. Begin by clamping the four case pieces together to form a peak. This provides a wider bearing surface for the router base, as well as a square shoulder for the router edge guide to ride against. Position the clamps as close to the ends of the pieces as possible without obstructing router travel. Then clamp everything in a vise or to the edge of your bench. The fence can be as simple as a straight piece of wood clamped to the router base. Position the fence so that the slot will be located near the inner edge of the miter. Then rout in the direction shown. After routing the first two slots on the inner pieces, establish the peak on the opposite ends of the case pieces and rout this set of inner miters. Next, reverse the sandwich and repeat the entire process. Paul Anthony PW contributor Clamp straight piece of wood to the router base to create fence Travel direction of router Clamp the four mitered workpieces together to form a peak Quick-cut Tenons: Two Cheeks in One Pass When using a tenoning j ig on the table saw, most woodworkers saw tenons one cheek at a time. This can be time-consuming and can lead to inaccuracies in tenon thickness, especially if the workpieces vary even a bit in thickness. I find it much quicker and more accurate to use two blades at once, with a spacer in between. This works great as long as your mortises are consistent in width, which they will be if cut with a router or hollow-chisel mortiser. You can buy thick metal shim s for spacers, but I simply use a 4"-diameter disk of hard wood cut from a strip of wood planed to the exact thickness needed. Use a dense, straight-grained wood such as maple (plywood works, too), and make sure the spacer is consistent in thickness to prevent any blade wobble. The initial planing, test-cutting and replaning to arrive at the perfect thickness may take a bit of time, but it's well worth the joint-cutting time saved in the future. I keep spacers for cutting tenons of various thickness, which work fine for repeated use as long as I always employ the same blades. If necessary, you can fine-tune the spacing using paper or metal shims. To make the cuts, I use the inner and outer blades from my dado set, but you could also use a pair of standard table saw blades. For safety, use a zero-clearance throat plate on your saw, and make sure to clamp the workpiece securely to the tenoning jig to make the cut. After cutting the tenon cheeks, I cut the shoulders on my sliding compound miter saw, although you could do this on the table saw after removing your tenoning setup. Bill Paine Lakeline, Ohio continued on page 24 18 Popular Woodworking February 2007 |