Popular Woodworking 2007-02 № 160, страница 23

to run the tenons. There's also a little logic behind my laziness. By making repeat cuts on the cheek of the tenon my blade leaves slight ridges on the surface. If test fitting my tenon achieves a fit that is too snug, I'm able to come back with a rabbeting plane and trim the tenon to fit. Miter the ends of the tenons to fit the legs. 13/8"-

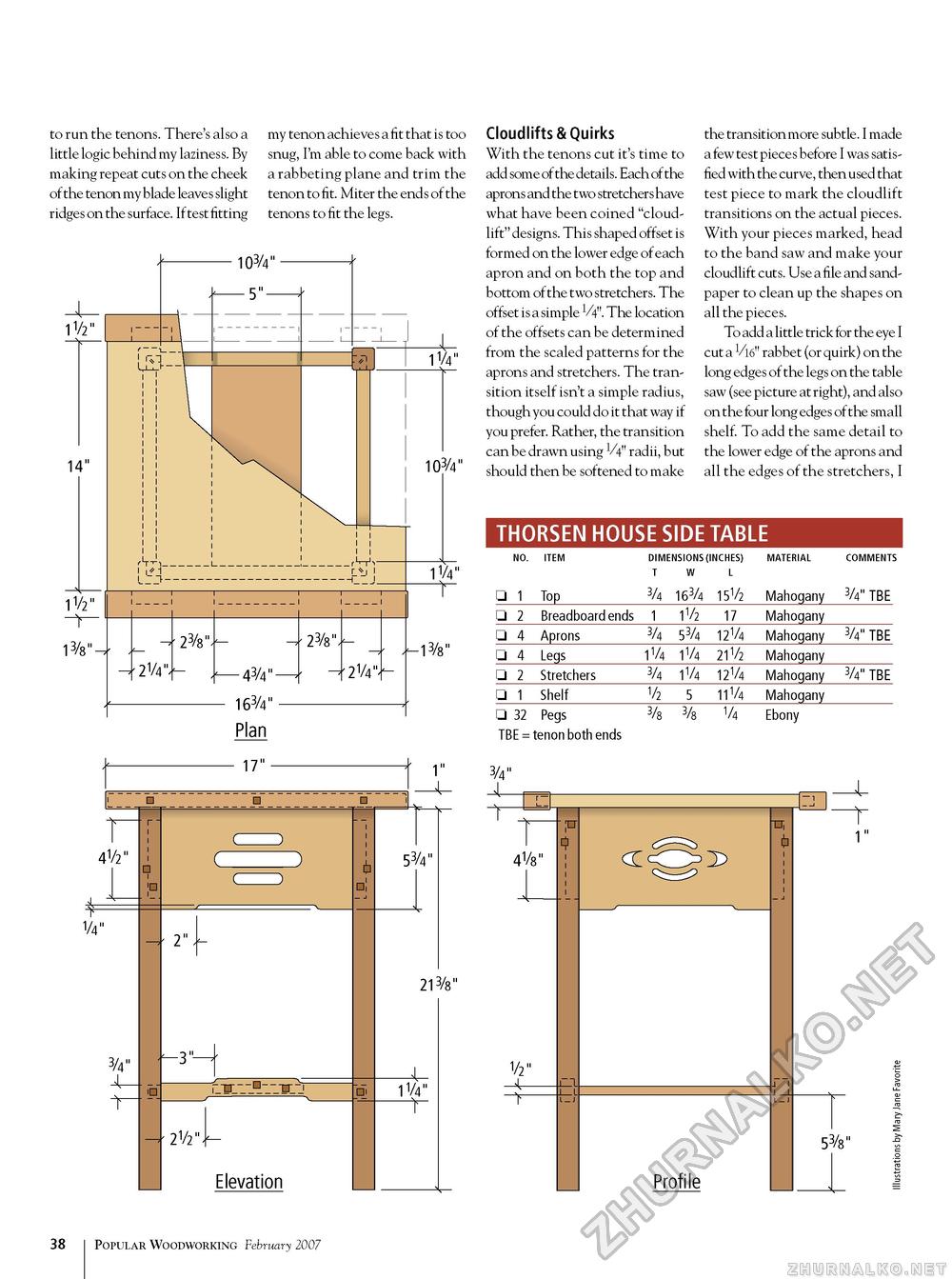

-13/8" 163/4" Plan - 17" - r 41/2" 1/4" 3/4" -u r o < ) ( ) 2" ^3- rrr—D—TJ"I 21/2" Elevation 1" -U 53/4" 213/8" 1V4" ~r Cloudlifts & Quirks With the tenons cut it's time to add some of the details. Each of the aprons and the two stretchers have what have been coined "cloud-lift" designs. This shaped offset is formed on the lower edge of each apron and on both the top and bottom of the two stretchers. The offset is a simple 1/4". The location of the offsets can be determined from the scaled patterns for the aprons and stretchers. The transition itself isn't a simple radius, though you could do it that way if you prefer. Rather, the transition can be drawn using 4" radii, but should then be softened to make the transition more subtle. I made a few test pieces before I was satisfied with the curve, then used that test piece to mark the cloudlift transitions on the actual pieces. With your pieces marked, head to the band saw and make your cloudlift cuts. Use a file and sandpaper to clean up the shapes on all the pieces. To add a little trick for the eye I cut a Vl6" rabbet (or quirk) on the long edges of the legs on the table saw (see picture at right), and also on the four long edges of the small shelf. To add the same detail to the lower edge of the aprons and all the edges of the stretchers, I THORSEN HOUSE SIDE TABLE

41/8" 1/2" jI_1 Profile IP T 1" 53/8" 10 Popular Woodworking February 2007 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||