Popular Woodworking 2007-04 № 161, страница 24

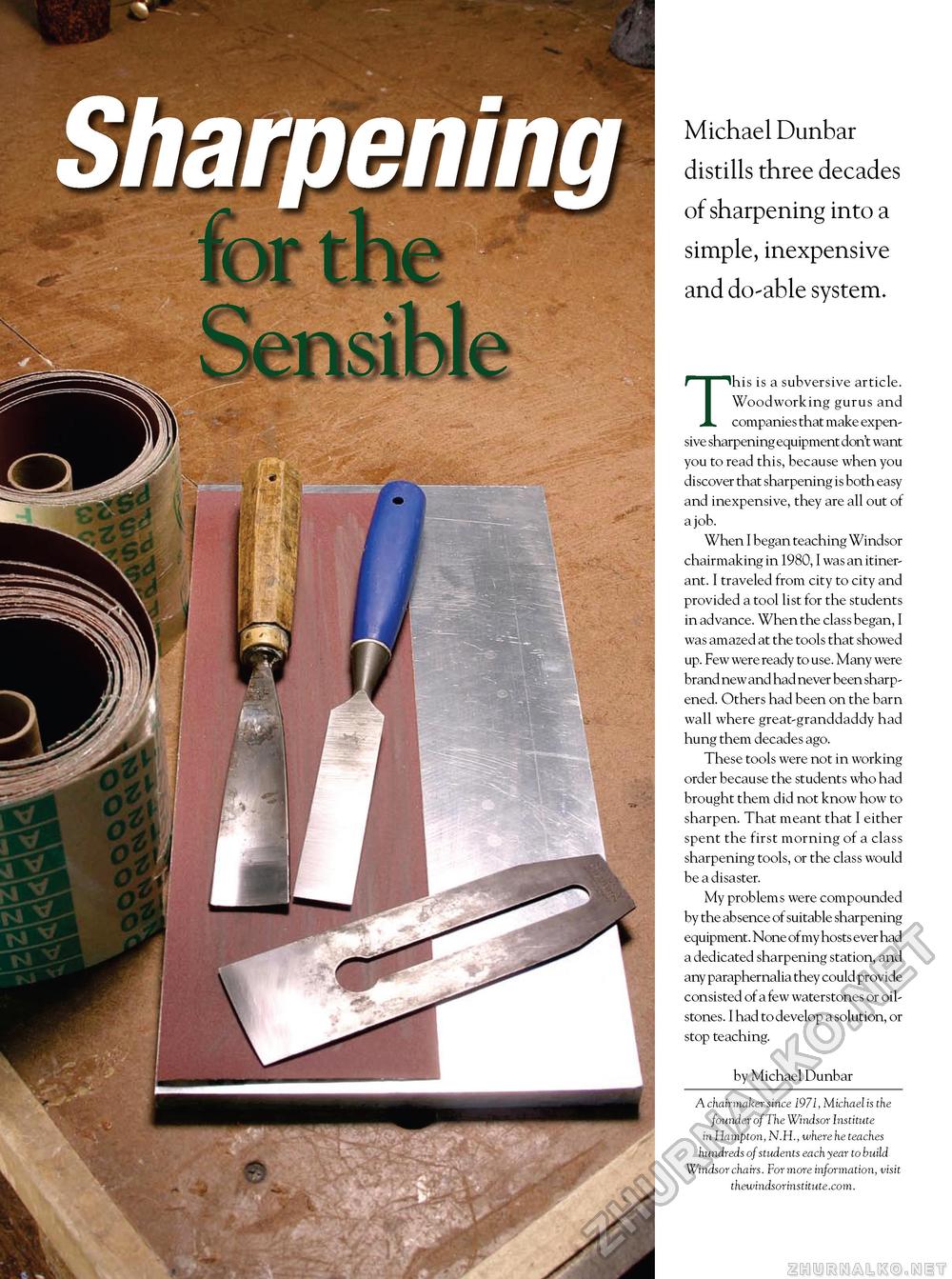

Michael Dunbar distills three decades of sharpening into a simple, inexpensive and do-able system. This is a subversive article. Woodworking gurus and companies that make expensive sharpening equipment don't want you to read this, because when you discover that sharpening is both easy and inexpensive, they are all out of a job. When I began teaching Windsor chairmaking in 1980, I was an itinerant. I traveled from city to city and provided a tool list for the students in advance. When the class began, I was amazed at the tools that showed up. Few were ready to use. Many were brand new and had never been sharpened. Others had been on the barn wall where great-granddaddy had hung them decades ago. These tools were not in working order because the students who had brought them did not know how to sharpen. That meant that I either spent the first morning of a class sharpening tools, or the class would be a disaster. My problems were compounded by the absence of suitable sharpening equipment. None of my hosts ever had a dedicated sharpening station, and any paraphernalia they could provide consisted of a few waterstones or oilstones. I had to develop a solution, or stop teaching. by Michael Dunbar A chairmaker since 1971, Michael is the founder of The Windsor Institute in Hampton, N.H., where he teaches hundreds of students each year to build Windsor chairs. For more information, visit thewindsorinstitute.com. |