Popular Woodworking 2007-04 № 161, страница 48

glue (we need to be able to remove them over the remainder of the project). Once the rods are in place you can test the door to the opening. If you have a problem it will most likely be binding at the top or bottom. In either case you will need to remove a sliver of material to allow the fit. This can be done at the jointer or with a plane. Both solutions require you to work carefully around the end grain. All that's left is to cut the plywood pieces that comprise the backs of the individual units and mill a number of pieces to use as the glass retainers from some scrap. Finish as Easy as the Project This finish technique was developed by Popular Woodworking Senior Editor Robert W. Lang. If this method had been around years ago when I was working with oak, I would have built many more projects from this hardwood. You will not find an easier finish anywhere that I know of. To begin, don't waste a huge amount of time sanding. I know you like the sound of that! Bring the piece to #120 grit with the random-orbit sander and finish sand by hand using #150-grit sandpaper. Done! Now you are ready to stain the bookcase. The staining process continues in the easy category. Rag on a coat of Olympic oil-based ""Special Walnut" stain. Apply an even coat and allow it to sit for 15 minutes before wiping any excess away. That coat needs to dry for 24 hours before moving on. Next up is one coat of Dark Walnut Watco Danish Oil. Apply this in the same fashion as the stain. Rag a coat onto the stained bookcase and allow that to cure for 15 minutes, then wipe away any extra oil with a clean rag. In this process the oil acts as a toner that will even the shading as it BARRISTER BOOKCASES □ 2 Case sides □ 3 Bottoms □ 3 Top front rails □ 3 Top back rails □ 3 Box catch rails □ 2 Top frame rails □ 2 Top frame sides □ 1 Top frame center support □ 1 Top frame catch rails □ 1 Front crown moulding □ 1 Side crown moulding □ 1 Case top □ 2 Base frame rails □ 2 Base frame sides □ 1 Base frame center support □ 1 Base frame front flat rail □ 1 Base frame back flat rail □ 1 Base moulding/front □ 1 Base moulding/sides □ 6 Door rails □ 4 Door stiles/tall □ 2 Door stiles/short □ 9 Glass retainer strips □ 1 Short unit back □ 2 Tall unit back * QSWO=Quartersawn White Oak

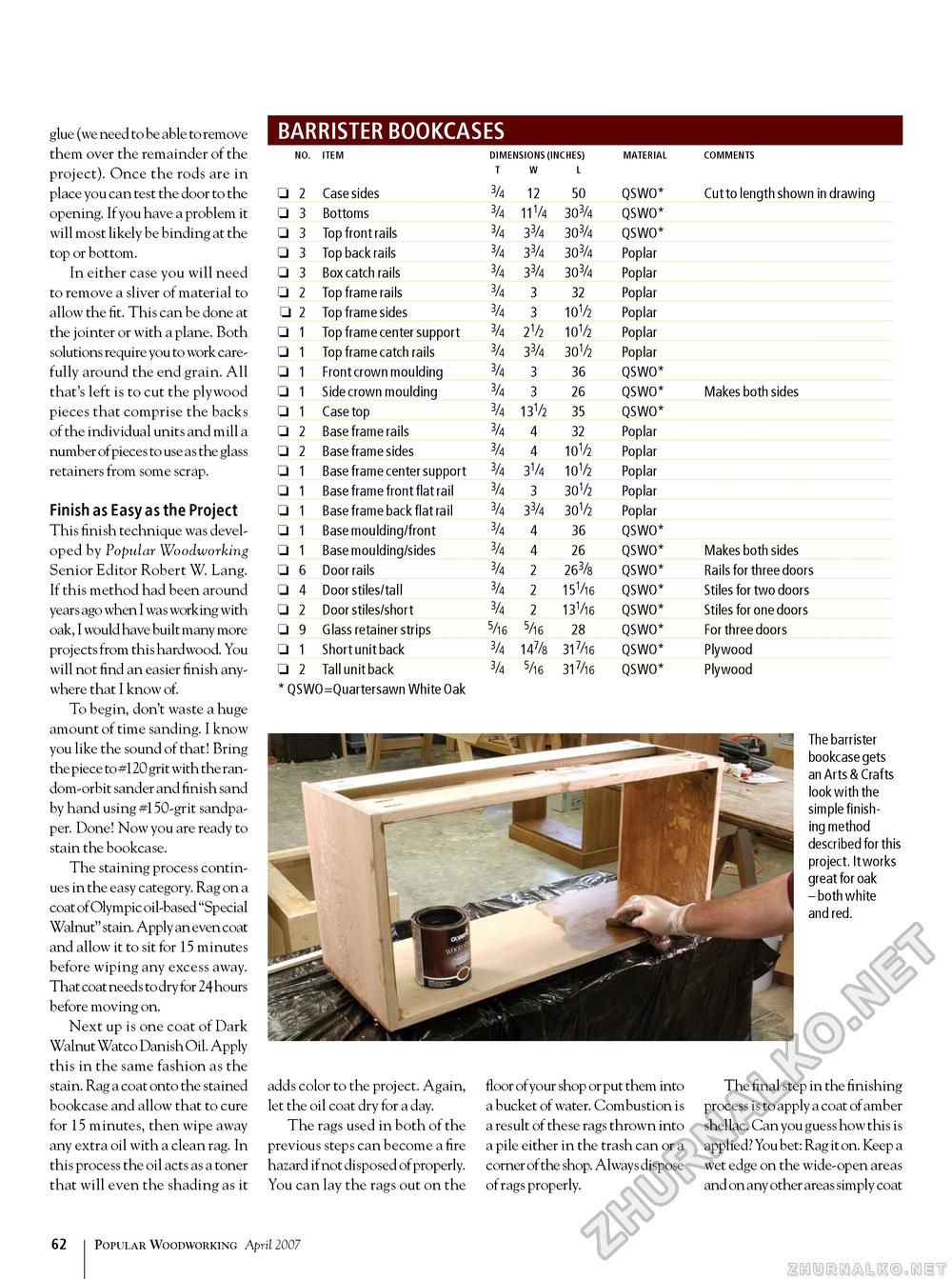

Cut to length shown in drawing Makes both sides Makes both sides Rails for three doors Stiles for two doors Stiles for one doors For three doors Plywood Plywood The barrister bookcase gets an Arts & Crafts look with the simple finishing method described for this project. It works great for oak - both white and red. adds color to the project. Again, let the oil coat dry for a day. The rags used in both of the previous steps can become a fire hazard if not disposed of properly. You can lay the rags out on the floor of your shop or put them into a bucket of water. Combustion is a result of these rags thrown into a pile either in the trash can or a corner of the shop. Always dispose of rags properly. The final step in the finishing process is to apply a coat of amber shellac. Can you guess how this is applied? You bet: Rag it on. Keep a wet edge on the wide-open areas and on any other areas simply coat 62 Popular Woodworking April 2007 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||