Popular Woodworking 2007-04 № 161, страница 67

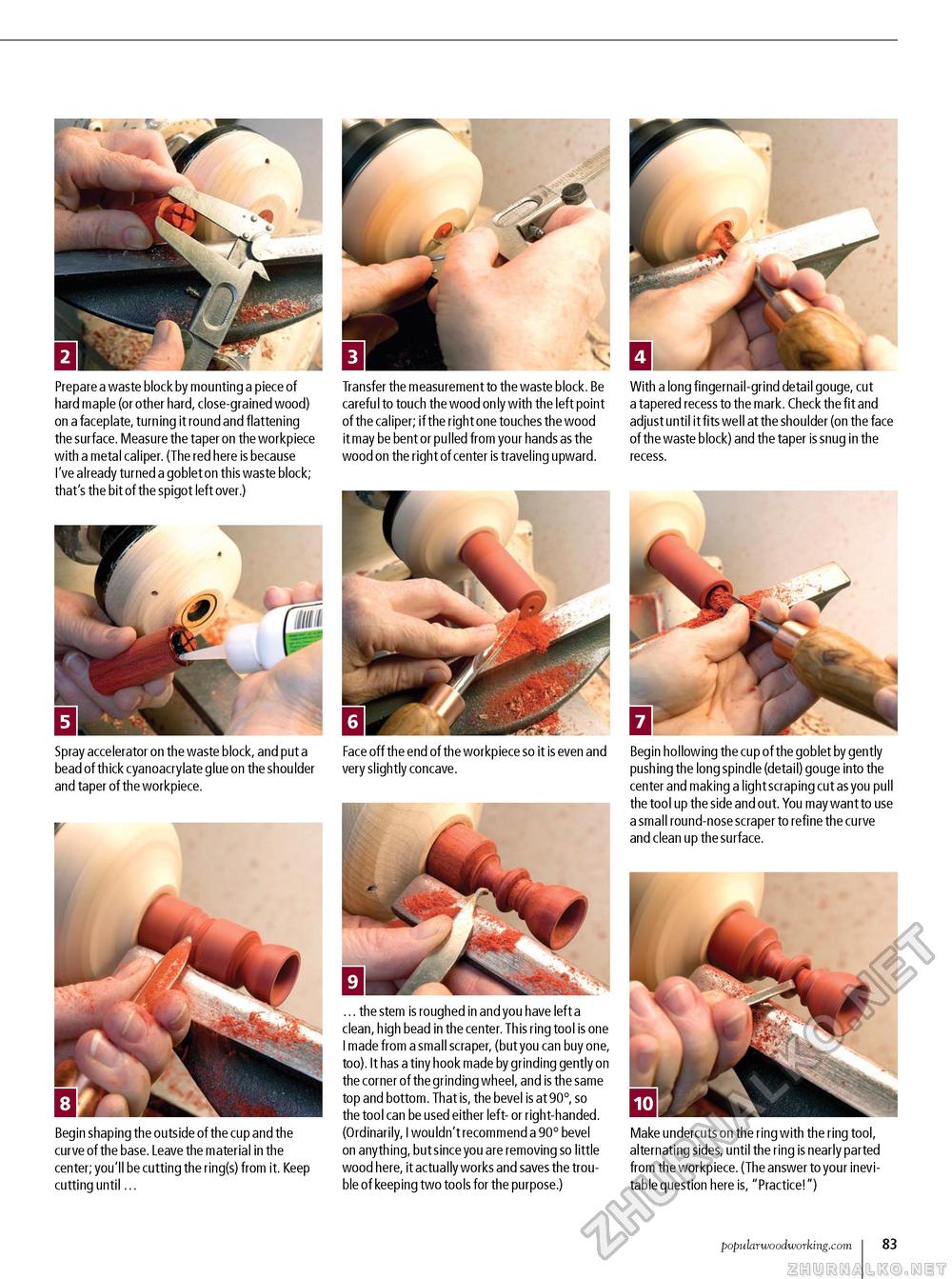

Prepare a waste block by mounting a piece of hard maple (or other hard, close-grained wood) on a faceplate, turning it round and flattening the surface. Measure the taper on the workpiece with a metal caliper. (The red here is because I've already turned a goblet on this waste block; that's the bit of the spigot left over.) Transfer the measurement to the waste block. Be careful to touch the wood on ly with the left point of the caliper; if the right one touches the wood it may be bent or pulled from your hands as the wood on the right of center is traveling upward. With a long fingernail-grind detail gouge, cut a tapered recess to the mark. Check the fit and adjust until it fits well at the shoulder (on the face of the waste block) and the taper is snug in the Spray accelerator on the waste block, and put a bead of th ick cyanoacrylate glue on the shoulder and taper of the workpiece. r Face off the end of the workpiece so it is even and very slightly concave. Begin hollowing the cup of the goblet by gently pushing the long spindle (detail) gouge into the center and making a light scraping cut as you pull the tool up the side and out. You may want to use a small round-nose scraper to refine the curve and clean up the surface. Begin shaping the outside of the cup and the curve of the base. Leave the material in the center; you'll be cutting the ring(s) from it. Keep cutting until ... ... the stem is roughed in and you have left a clean, high bead in the center. This ring tool is one I made from a small scraper, (but you can buy one, too). It has a tiny hook made by grinding gently on the corner of the grinding wheel, and is the same top and bottom. That is, the bevel is at 90°, so the tool can be used either left- or right-handed. (Ordinarily, I wouldn't recommend a 90° bevel on anything, but since you are removing so little wood here, it actually works and saves the trouble of keeping two tools for the purpose.) Make undercuts on the ring with the ring tool, alternating sides, until the ring is nearly parted from the workpiece. (The answer to your inevitable question here is, "Practice!") recess. popularwoodworking.com I 83 |