Popular Woodworking 2007-04 № 161, страница 71

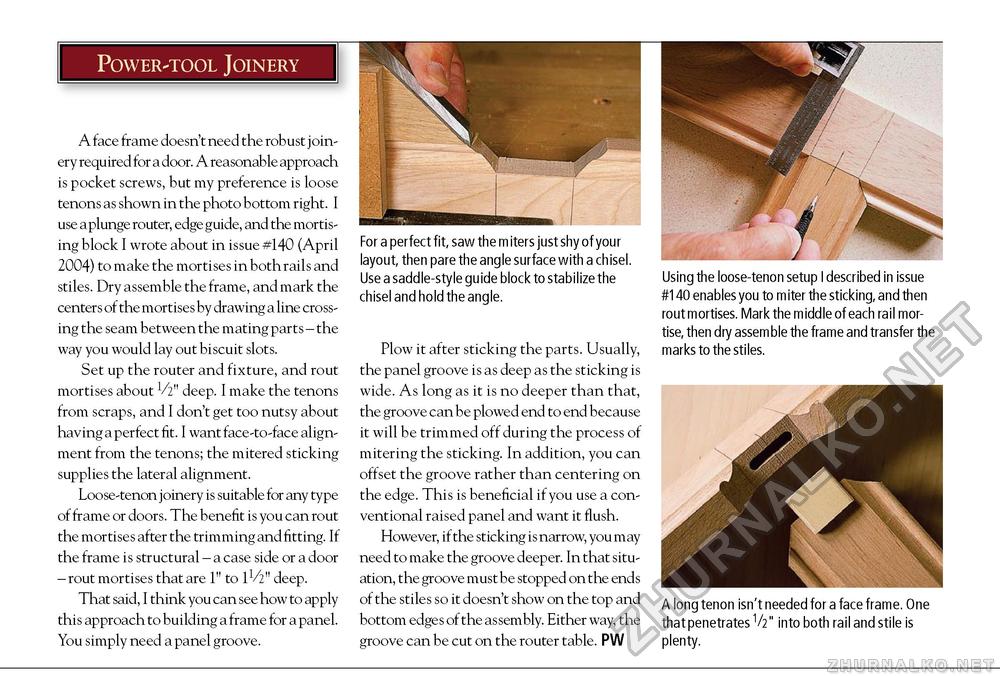

Power-tool Joinery A face frame doesn't need the robust joinery required for a door. A reasonable approach is pocket screws, but my preference is loose tenons as shown in the photo bottom right. I use a plunge router, edge guide, and the mortising block I wrote about in issue #140 (April 2004) to make the mortises in both rails and stiles. Dry assemble the frame, and mark the centers of the mortises by drawing a line crossing the seam between the mating parts - the way you would lay out biscuit slots. Set up the router and fixture, and rout mortises about V2" deep. I make the tenons from scraps, and I don't get too nutsy about having a perfect fit. I want face-to-face alignment from the tenons; the mitered sticking supplies the lateral alignment. Loose-tenon joinery is suitable for any type of frame or doors. The benefit is you can rout the mortises after the trimming and fitting. If the frame is structural - a case side or a door - rout mortises that are 1" to 1V2" deep. That said, I think you can see how to apply this approach to building a frame for a panel. You simply need a panel groove. For a perfect fit, saw the m iters just shy of your layout, then pare the angle surface with a chisel Use a saddle-style guide block to stabilize the chisel and hold the angle. Plow it after sticking the parts. Usually, the panel groove is as deep as the sticking is wide. As long as it is no deeper than that, the groove can be plowed end to end because it will be trimmed off during the process of mitering the sticking. In addition, you can offset the groove rather than centering on the edge. This is beneficial if you use a conventional raised panel and want it flush. However, if the sticking is narrow, you may need to make the groove deeper. In that situation, the groove must be stopped on the ends of the stiles so it doesn't show on the top and bottom edges of the assembly. Either way, the groove can be cut on the router table. PW Using the loose-tenon setup I described in issue #140 enables you to miter the sticking, and then rout mortises. Mark the middle of each rail mortise, then dry assemble the frame and transfer the marks to the stiles. A long tenon isn't needed for a face frame. One that penetrates 1h" into both rail and stile is plenty. |