Popular Woodworking 2007-10 № 164, страница 40

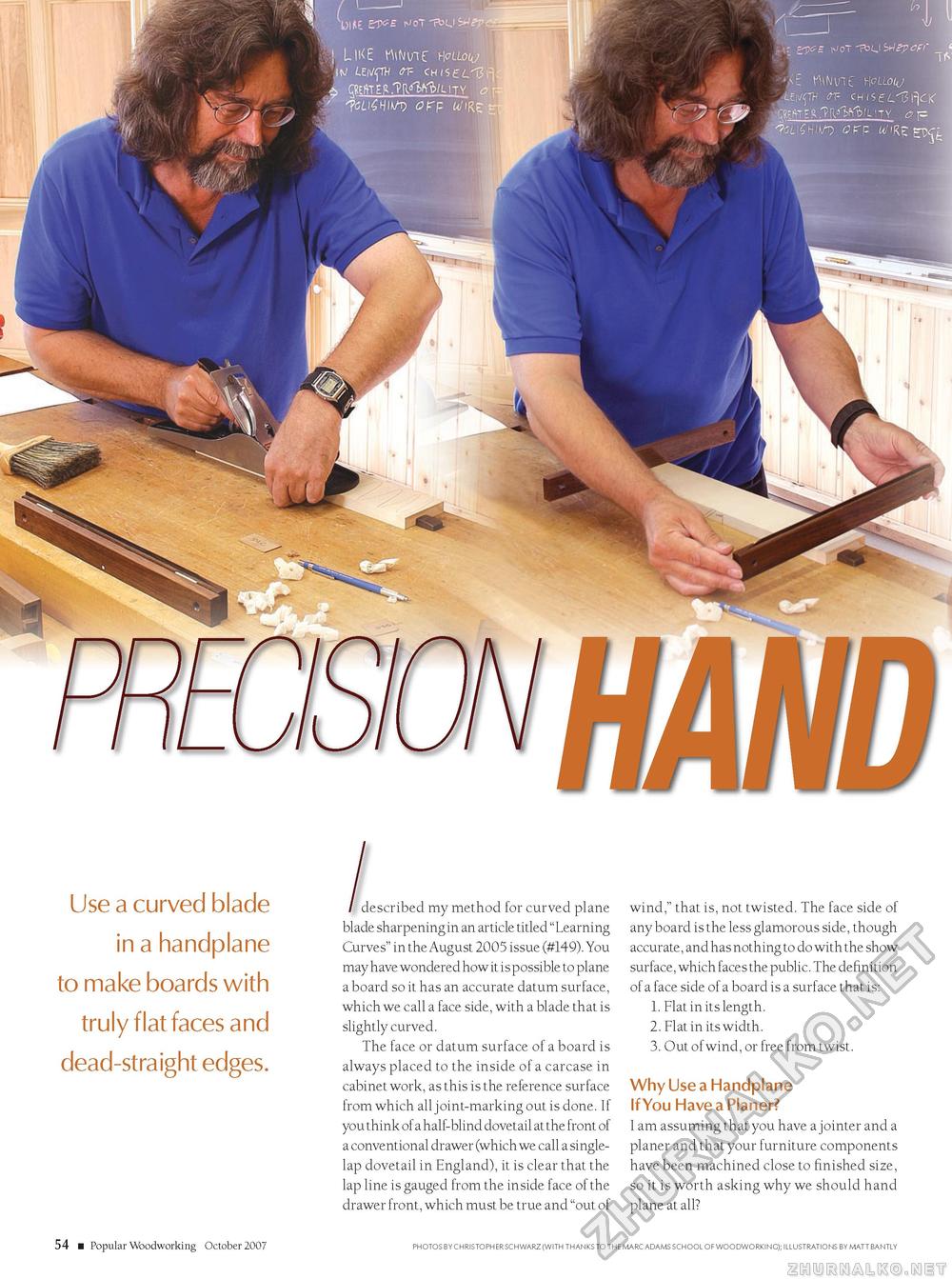

We. ijot fbyw^ra | LIKE flnnC HvLLoti/ ||j (.Ejl/<fW OT- <Hi<ieL-T;ir\C. p MT£S.TR»'W!'fi.iTY <5 p ' ''ftii^iws orp wire: E | = I^JOT ft>U off _ :,.<£ Mnnc H°Sft| liE/ipg cKise^ij^cic Use a curved blade in a handplane to make boards with truly flat faces and dead-straight edges. described my method for curved plane blade sharpening in an article titled "Learning Curves" in the August 2005 issue (#149). You may have wondered how it is possible to plane a board so it has an accurate datum surface, which we call a face side, with a blade that is slightly curved. The face or datum surface of a board is always placed to the inside of a carcase in cabinet work, as this is the reference surface from which all j oint-marking out is done. If you think of a half-blind dovetail at the front of a conventional drawer (which we call a single-lap dovetail in England), it is clear that the lap line is gauged from the inside face of the drawer front, which must be true and "out of wind," that is, not twisted. The face side of any board is the less glamorous side, though accurate, and has nothing to do with the show surface, which faces the public. The definition of a face side of a board is a surface that is: 1. Flat in its length. 2. Flat in its width. 3. Out of wind, or free from twist. Why Use a Handplane If You Have a Planer? I am assuming that you have a jointer and a planer and that your furniture components have been machined close to finished size, so it is worth asking why we should hand plane at all? 54 ■ Popular Woodworking October 2007 photos by christopher schwarz (with thanks to the marc adams school of woodworking); illustrations by matt bantly |