Popular Woodworking 2007-12 № 166, страница 19

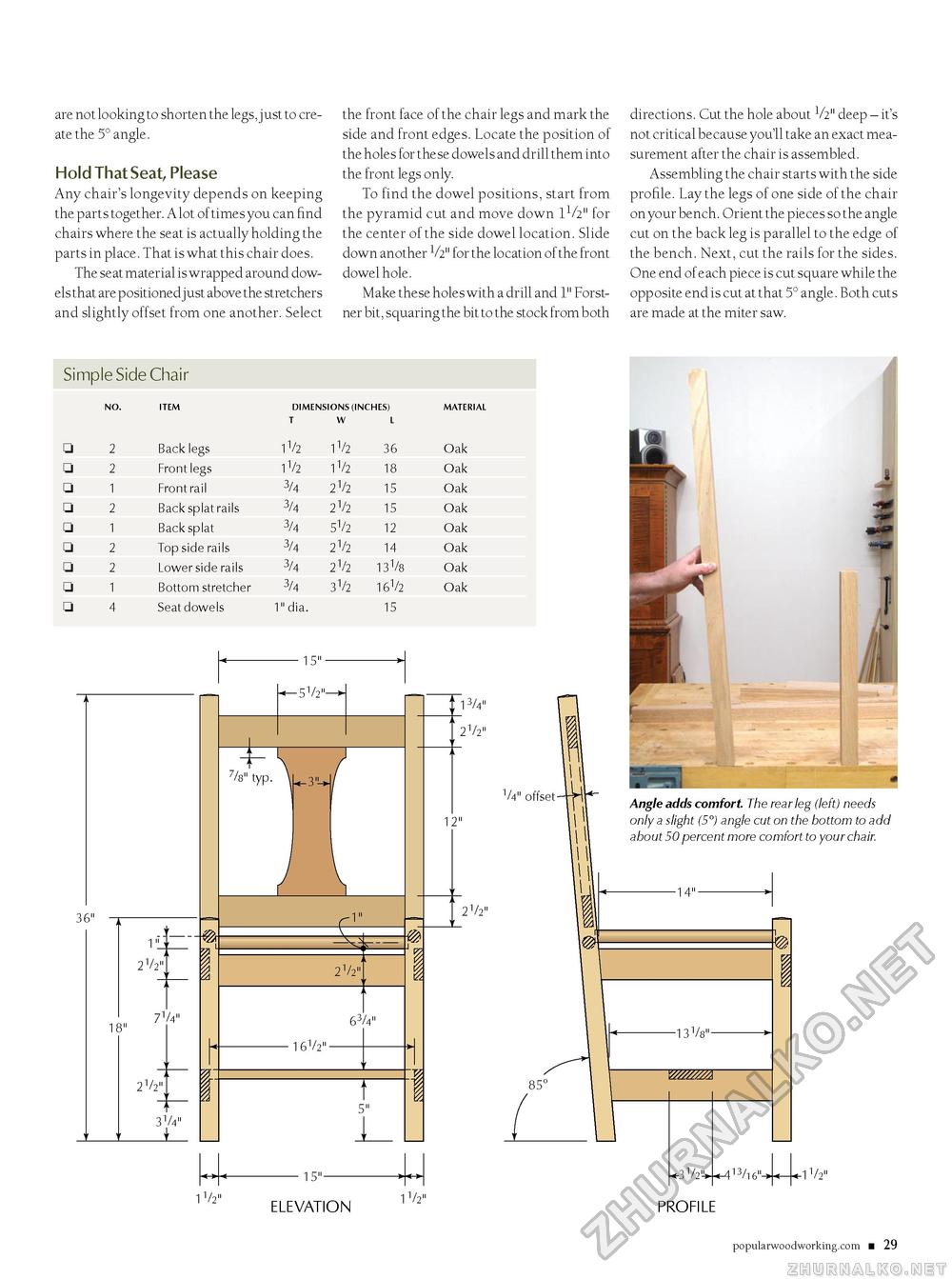

are not looking to shorten the legs, just to create the 5° angle. Hold That Seat, Please Any chair's longevity depends on keeping the parts together. A lot of times you can find chairs where the seat is actually holding the parts in place. That is what this chair does. The seat material is wrapped around dowels that are positionedjust above the stretchers and slightly offset from one another. Select the front face of the chair legs and mark the side and front edges. Locate the position of the holes for these dowels and drill them into the front legs only. To find the dowel positions, start from the pyramid cut and move down 11/2" for the center of the side dowel location. Slide down another V2" for the location of the front dowel hole. Make these holes with a drill and 1" Forst-ner bit, squaring the bit to the stock from both directions. Cut the hole about V2" deep - it's not critical because you'll take an exact measurement after the chair is assembled. Assembling the chair starts with the side profile. Lay the legs of one side of the chair on your bench. Orient the pieces so the angle cut on the back leg is parallel to the edge of the bench. Next, cut the rails for the sides. One end of each piece is cut square while the opposite end is cut at that 5° angle. Both cuts are made at the miter saw.

36" 21/2" 18" 71/4" 21/2" 31/4" I' -15"- _51/2". 7/8" typ. -3% 21/2i 63/4" -161/2"- 15" 11/2" 11/," 1 /2 elevation 1 1 3/4" 21/2" 12" Angle adds comfort. The rear leg (left) needs only a slight (5°) angle cut on the bottom to add about 50 percent more comfort to your chair. 21/2" 1 1/2" popularwoodworking.com ■ 29 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||