Popular Woodworking 2008-10 № 171, страница 24

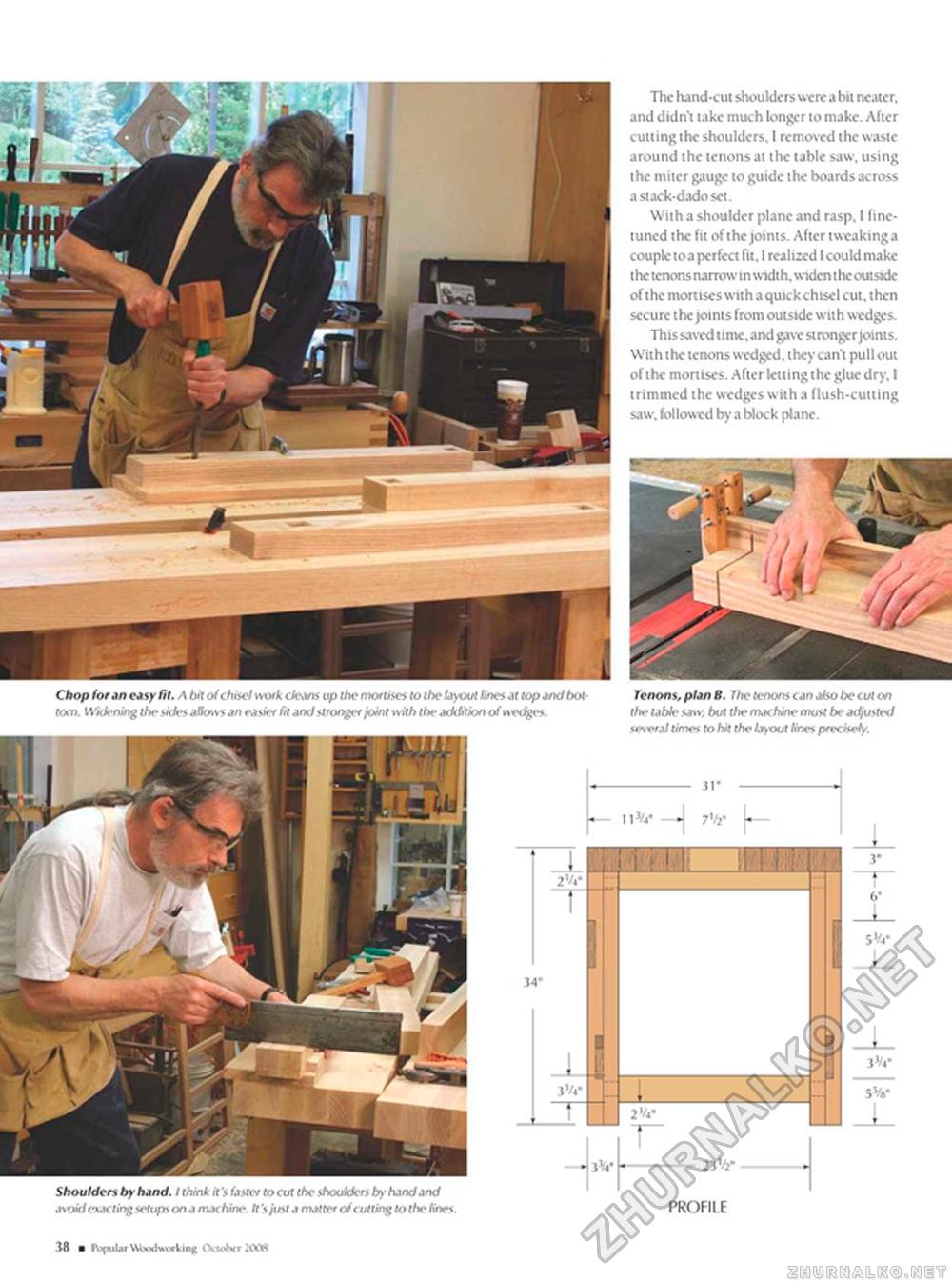

The hand-cut shoulders were a bit neater, and didn't take much longer to make. After cutting the shoulders. I removed the waste around the tenons at the table saw, using the miter gauge to guide the boards across a stack-dado set. With a shoulder plane and rasp. I fine-tuned the fit of the joints. After tweakinga couple toa perfect fit, I realized I could make the tenons narrow in width, widen the outside of the mortises with a quick chisel cut. then secure the joints from outside with wedges. This saved time, and gave stronger joints. With the tenons wedged, they can't pull out of the mortises. After letting the glue dry. I trimmed the wedges with a flush-cutting saw. fol lowed by a block plane. Shoulders by hind. I think it's inter to cut the shoulders by hand and a soid ewe ting setups on a machine. fr's just a nutter oi cutting to the lines. Chop for an easy fit. A bit of chisel work cleans up the mortises to the layout lines at top and bottom. Widening the sides aUcnss an easier fit and stronger joint with the addition of isedges. Tenons, plan B. I Ik-tenons can also be cut on the table saw, but the machine must be adjusted seseral times to hit the layout lines precisely. 38 ■ IVipulai WUxhnjrfcing (H«otwr 200C |