Popular Woodworking 2008-11 № 172, страница 25

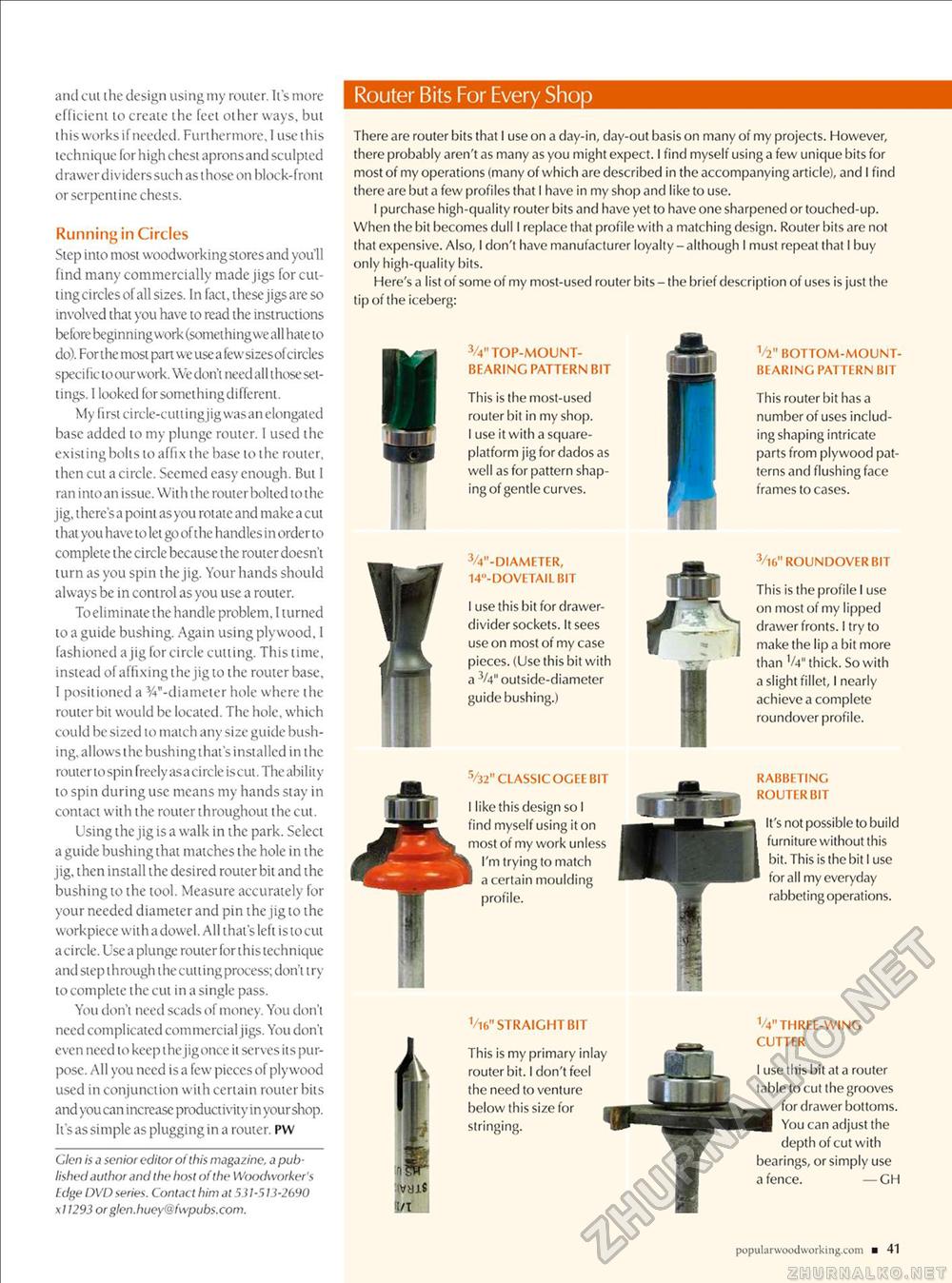

and cut ihe design using my rouier. lis more efficient lo create ihe feel other ways, bui t his works if needed. Furthermore, I use this technique for high chest aprons and sculpted drawerdividerssuch asthose on block-front or serpentine chests. Running in Circles Step into most woodworking stores and you'll find many commercially made jigs for culling circles of all sizes. In fact, these jigs are so involved thai you have 10 read the instructions before beginning work (something we all hate to do). For ihe most part we use a few sizes of circles spedfic to ou r work. We don'i need all those sellings. 1 looked forsomethingdifferent. My fi rsi ci rcle-cutl i ng j ig was an elongated base added to my plunge router. I used ihe existing bolts to affix the base to the router, then cut a circle. Seemed easy enough. But I ran inioan issue. With the rouier bolted to the jig, there's a point as you rotate and make a cut that you have 10 let go of the handles i n order to complete the circle because the rouier doesn't turn as you spin the jig. Your hands should always be in control as you use a rouier. Toeliminate ihe handle problem, I turned to a guide bushing. Again using plywood. 1 fashioned a jig for circle culling. This lime, instead of affixing thejig to the router base, I positioned a W-diameier hole where the router bit would be located. The hole, which could be sized to match any size guide bushing, allows ihe bushing that's installed in the rouier to spi n freely as a circle is cut. The ability to spin during use means my hands stay in contact wiih ihe rouier throughout the cut. Using the jig is a walk in ihe park. Select a guide bushing that matches the hole in the jig, then install the desired rouier bii and the bushing to the tool. Measure accurately for your needed diameter and pin the jig 10 the workpiece with a dowel. All that's left is tocut a circle. Use a plunge router for this technique and step through the cutting process; don't try to complete the cut in a single pass. You don't need scads of money. You don't need complicated commercial jigs. You don't even need to keep thejig once ii serves its purpose. All you need is a few pieces of plywood used in conjunction with certain rouier bits and you can increase productivity in vourshop. It's as simple as plugging in a rouier. pw Glen is a senior editor of this magazine, a published author and the host of the Woodworker's Edge DVD series. Contact him at 5J1-513-2690 xl1293 orglen.huey@fwpubs.com. Router Bits For Every Shop There are router bits that I use on a day-in, day-out basis on many of my projects. However, there probably aren't as many as you might expect. I find myself using a few unique bits for most of my operations (many of which are described in the accompanying article), and I find there are but a few profiles that I have in my shop and like to use. I purchase high-quality router bits and have yet to have one sharpened or touched-up. When Ihe bit becomes dull I replace that profile with a matching design. Router bits are not that expensive. Also, I don't have manufacturer loyalty -although I must repeat that I buy only high-quality bits. Here's a list of some of my most-used router bits - the brief description of uses is just the tip of the iceberg: 1/2" bottom-mount-bearing pattern bit This router bit has a number of uses including shaping intricate parts from plywood patterns and flushing face frames lo cases. 3/l6" roundoverbit This is the profile I use on most of my lipped drawer fronts. I try to make the lip a bit more than V4" thick. So with a slight fillet, I nearly achieve a complete roundover profile. vais l/T 3/4" TOP-MOUNT-BEARING PATTERN BIT This is the most-used router bit in my shop. I use it with a square-platform jig for dados as well as for pattern shaping of gentle curves. 3/4"-diameter, 14"-dovetail bit I use this bit for drawer-divider sockets. It sees use on most of my case pieces. (Use this bit with a 3/4" outside-diameter guide bushing.) V32" classic ogee bit I like this design so I find myself using it on most of my work unless I'm trying to match a certain moulding profile. rabbeting router bit It's not possible to build furniture without this bit. This is the bit I use for all my everyday rabbeting operations. 1/i6" STRAIGHT BIT This is my primary inlay router bit. I don't feel the need to venture below this size for stringing. 1/4" three-wing cutter I use this bit at a router table to cut the grooves for drawer bottoms. You can adjust the depth of cut with bearings, or simply use a fence. —GH popularwooclworking.com ■ 41 |