Popular Woodworking 2008-12 № 173, страница 10

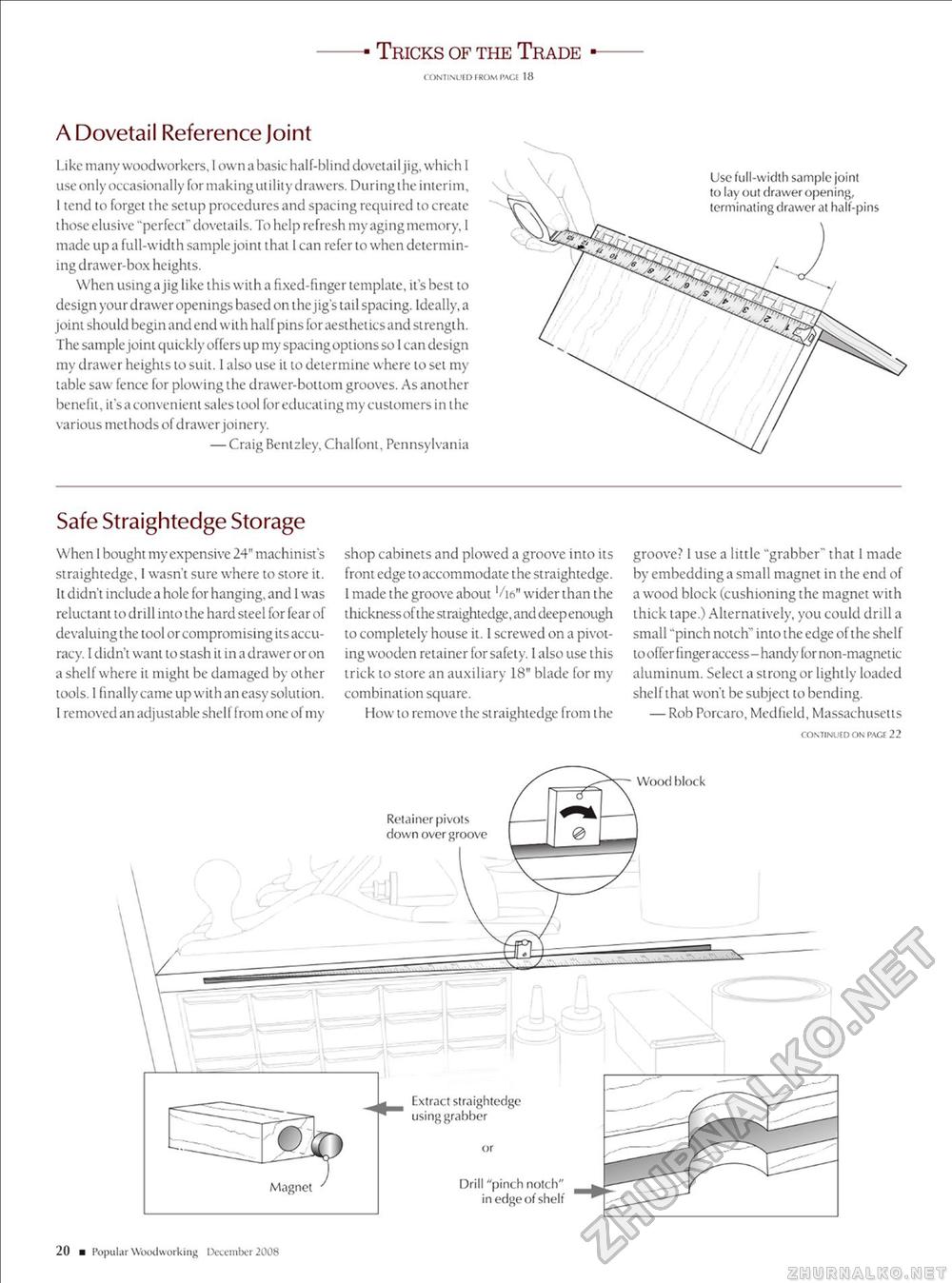

Tricks of the Trade CONTINUED FROM PACE 18 A Dovetail Reference Joint like many woodworkers, I own a basic half-blind dovetail jig, which 1 use only occasionally for making utility drawers. During the interim, I tend to forget the setup procedures and spacing required to create t hose elusive "perfect" dovetails. To help refresh my aging memory, I made up a full-width sample joint that 1 can refer to when determining drawer-box heights. When usinga jig like this with a fixed-finger template, its best to design your drawer openings based on the jig's tail spacing. Ideally, a joint should begin and end with half pins for aesthetics and strength. The sample joint quickly offers up my spacing options so 1 can design my drawer heights to suit. 1 also use it to determine where to set my table saw fence for plowing the drawer-bottom grooves. As another benefit, it's a convenient sales tool for educating my customers in the various methods of drawer joinery. — Craig Bcntzley, Chalfont, Pennsylvania Safe Straightedge Storage When I bought my expensive 24" machinist's straightedge, I wasn't sure where to store it. It didn't include a hole for hanging, and 1 was reluctant to drill into the hard steel for fear of devaluing the tool or compromising its accuracy. 1 didn't want to stash it in a drawer or on a shelf where it might be damaged by other tools. 1 finally came up with an easy solution. 1 removed an adjustable shelf from one of my shop cabinets and plowed a groove into its front edge to accommodate the straightedge. I made the groove about '/i6H wider than the thickness of the straightedge, and deepenough to completely house it. I screwed on a pivoting wooden retainer for safety. I also use this trick to store an auxiliary 18" blade for my combination square. How to remove the straightedge from the groove? 1 use a little "grabber" that 1 made by embedding a small magnet in the end of a wood block (cushioning the magnet with thick tape.) Alternatively, you could drill a small "pinch notch" into the edge of the shelf to offer finger access - handy for non-magnetic aluminum. Select a strong or lightly loaded shelf that won't be subject to bending. — Rob Porcaro, Medfield, Massachusetts CONTINUED ON PACE 22 Use full-width sample joint tf) lay out drawer opening, terminating drawer at half-pins Magnet Retainer pivots down over groove Wood block Extract straightedge using grabber Drill "pinch notch" in edge of shelf 20 ■ Popul ar Woodworking December 2008 |