Popular Woodworking 2008-12 № 173, страница 11

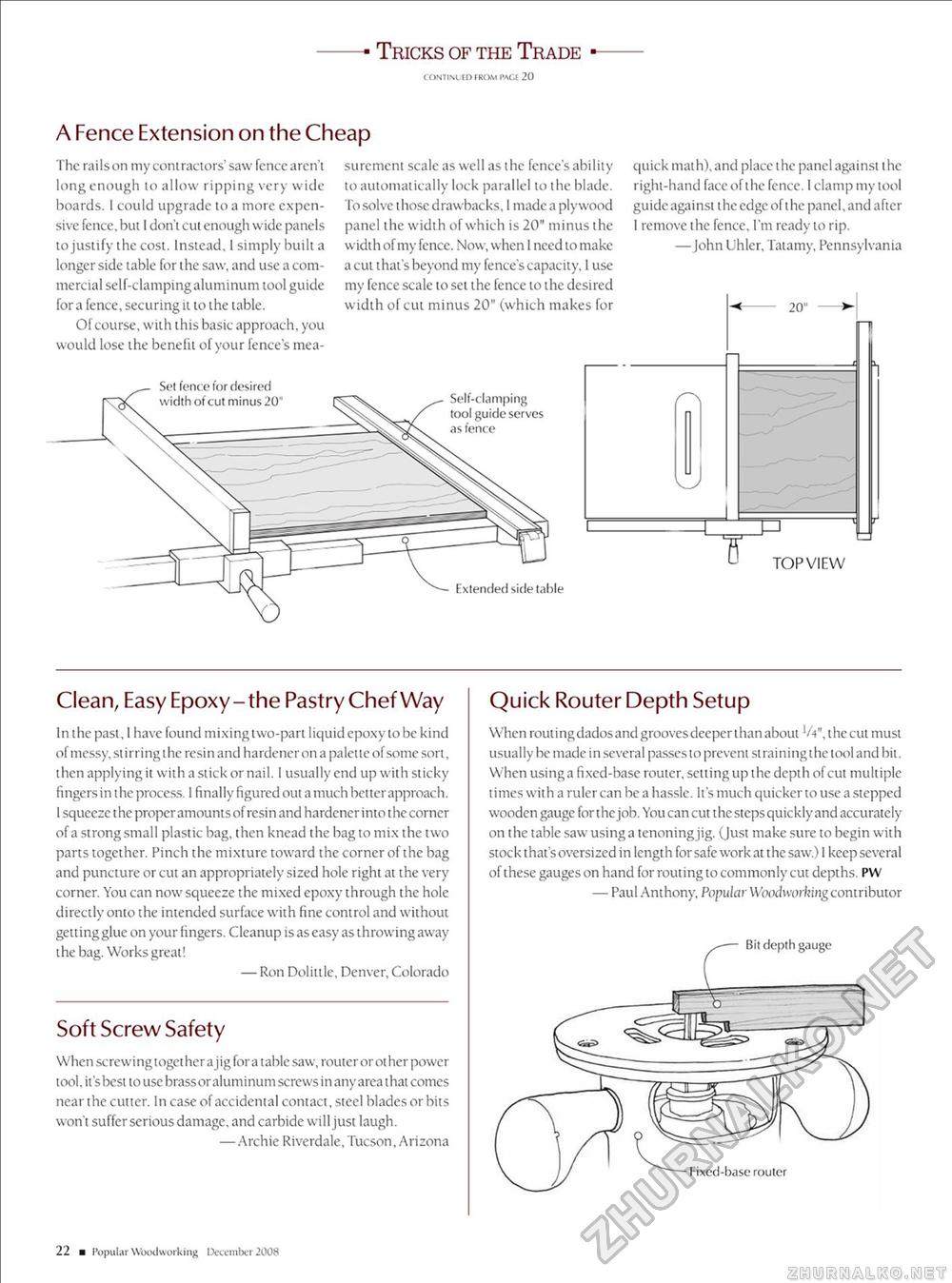

- Tricks of the Trade CONTINUED fROM PACE 20 A Fence Extension on the Cheap The rails on my contractors' saw fence aren't long enough to allow ripping very wide hoards. I could upgrade to a more expensive fence, but I don't cut enough wide panels to justify the cost. Instead, 1 simply built a longer side table for the saw, and use a commercial self-clamping aluminum tool guide for a fence, securing it to the table. Of course, with this basic approach, you would lose the benefit of your fence's mea surement scale as well as the fence's ability to automatically lock parallel to the blade. To solve those drawbacks, I made a plywood panel the width of which is 20" minus the width of my fence. Now, when 1 need to make a cut that's beyond my fence's capacity. 1 use my fence scale to set the fence to the desired width of cut minus 20" (which makes for quick math), and place the panel against the right-hand faceofthe fence. 1 clamp my tool guide against the edge of the panel, and after I remove the fence. I'm ready to rip. —John Uhler, Tat amy, Pennsylvania TOP VIEW Clean, Easy Epoxy-the Pastry Chef Way In the past, 1 have found mixing two-part liquid epoxy to be kind of messy, stirring the resin and hardener on a palette of some sort, then applying it with a stick or nail. I usually end up with sticky fingers in the process. I finally figured out a much betterapproach. 1 squeeze the proper amounts of resin and hardenerinto the corner of a strong small plastic bag, then knead the bag to mix the two parts together. Pinch the mixture toward the corner of the bag and puncture or cut an appropriately sized hole right at the very corner. You can now squeeze the mixed epoxy through the hole directly onto the intended surface with fine control and without gettingglue on your lingers. Cleanup is as easy as throwing away the bag. Works great! — Ron Dolittle, Denver, Colorado Soft Screw Safety When screwing toget her a jig for a table saw, router or ot her power tool, it's best to use brassor aluminum screws in any area that comes near the cutter. In case of accidental contact, steel blades or bits won't suffer serious damage, and carbide will just laugh. — Archie Riverdale, Tucson, Arizona Quick Router Depth Setup When routing dados and groovesdeeper than about 'A", the cut must usually be made in several passes to prevent straining the tool and bit. When using a fixed-base router, setting up the depth of cut multiple times with a ruler can be a hassle. It's much quicker to use a stepped wooden gauge for the job. You can cut the steps quickly and accurately on the table saw using a tenoning jig. (Just make sure to begin with stock that's oversized in length for safe work at the saw.) I keep several of these gauges on hand for routing to commonly cut depths. PW — Paul Anthony, Popular Woodworking contributor Extended side table Sel fence for desired Self-clamping tool guide serves as fence 22 ■ Popul ar Woodworking December 2008 |