Popular Woodworking 2008-12 № 173, страница 53

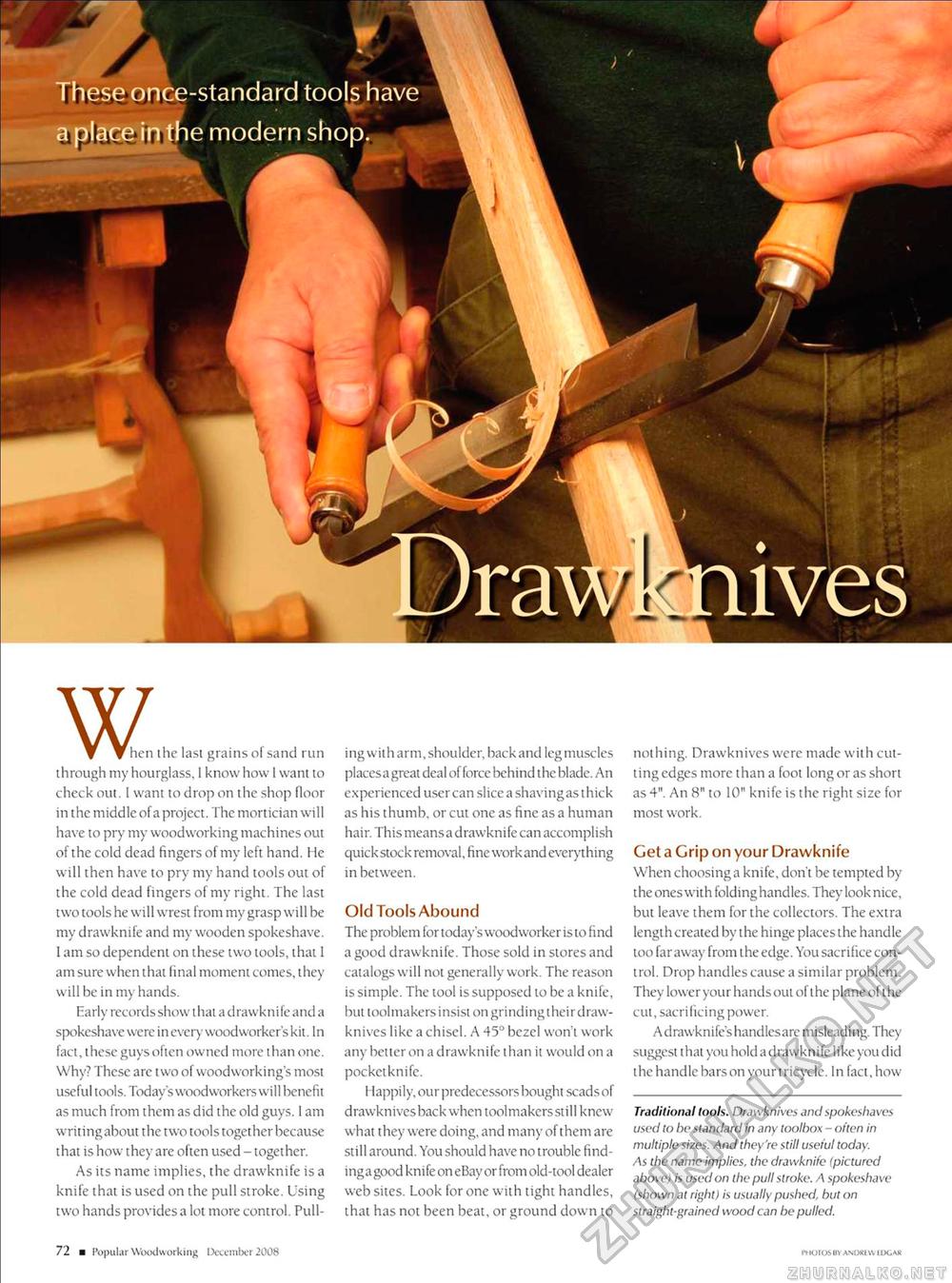

ce-sta he m r W Y ▼hen l hen the last grains of sand run through my hourglass, I know how I want to check out. 1 want to drop on the shop floor in the middle of a project. The mortician will have to pry my woodworking machines out of the cold dead fingers of my left hand. He will then have to pry my hand tools out of the cold dead fingers of my right. The last two tools he will wrest from my grasp will be my drawknife and my wooden spokeshave. 1 am so dependent on these two tools, that 1 am sure when that final moment comes, they will be in my hands. Early records show t hat a drawknife and a spokeshave were in every woodworkers kit. In fact, t hose guys often owned more t ban one. Why? These are two of woodworking's most useful tools. Today's woodworkers will benefit as much from them as did the old guys. I am writing about the two tools together because that is how they are often used - together. As its name implies, the drawknife is a knife that is used on the pull stroke. Using two hands provides a lot more control. Pull ing wit h arm, shoulder, back and leg muscles places a great deal of force behind t he blade. An experienced user can slice a shaving as thick as his thumb, or cut one as fine as a human hair. This means a drawknife can accomplish quick stock removal, fine work and everything in between. Old Tools Abound The problem for today's woodworker is to find a good drawknife. Those sold in stores and catalogs will not generally work. The reason is simple. The tool is supposed to be a knife, but tool makers i nsist on grinding t hei r d raw-knives like a chisel. A 45° bezel won't work any better on a drawknife than it would on a pocket knife. I lappily, our predecessors bought scads of drawknives back when toolmakers still knew what they were doing, and many of them are still around. You should have no trouble find-ingagood knife on eBay or from old-tool dealer websites. Look for one with tight handles, that has not been beat, or ground down to nothing. Drawknives were made with cutting edges more than a foot long or as short as 4". An 8" to 10" knife is the right size for most work. Get a Crip on your Drawknife When choosing a knife, don't be tempted by the ones with folding handles. They look nice, but leave them for the collectors. The extra length created by the hinge places the handle too faraway from the edge. You sacrifice control. Drop handles cause a similar problem. They lower your hands out of the plane ol the cut, sacrificing power. A d rawkn ife's handles a re misleading. They suggest that you hold a drawknife like you did the handle bars on your t ricycle. In fact, how Traditional tools. Drawknives and spokeshaves used to be standard in any toolbox - often in multiple sizes. And they're still useful today. As the name implies, the drawknife (pictured above) is used on the pull stroke. A spokeshave (shown at right) is usually pushed, but on straight-grained wood can be pulled. 71 m PopularWooilworking Dcccmber 2008 Pf lOIOSllY ANDRtW UX>Mt |