Popular Woodworking 2009-02 № 174, страница 13

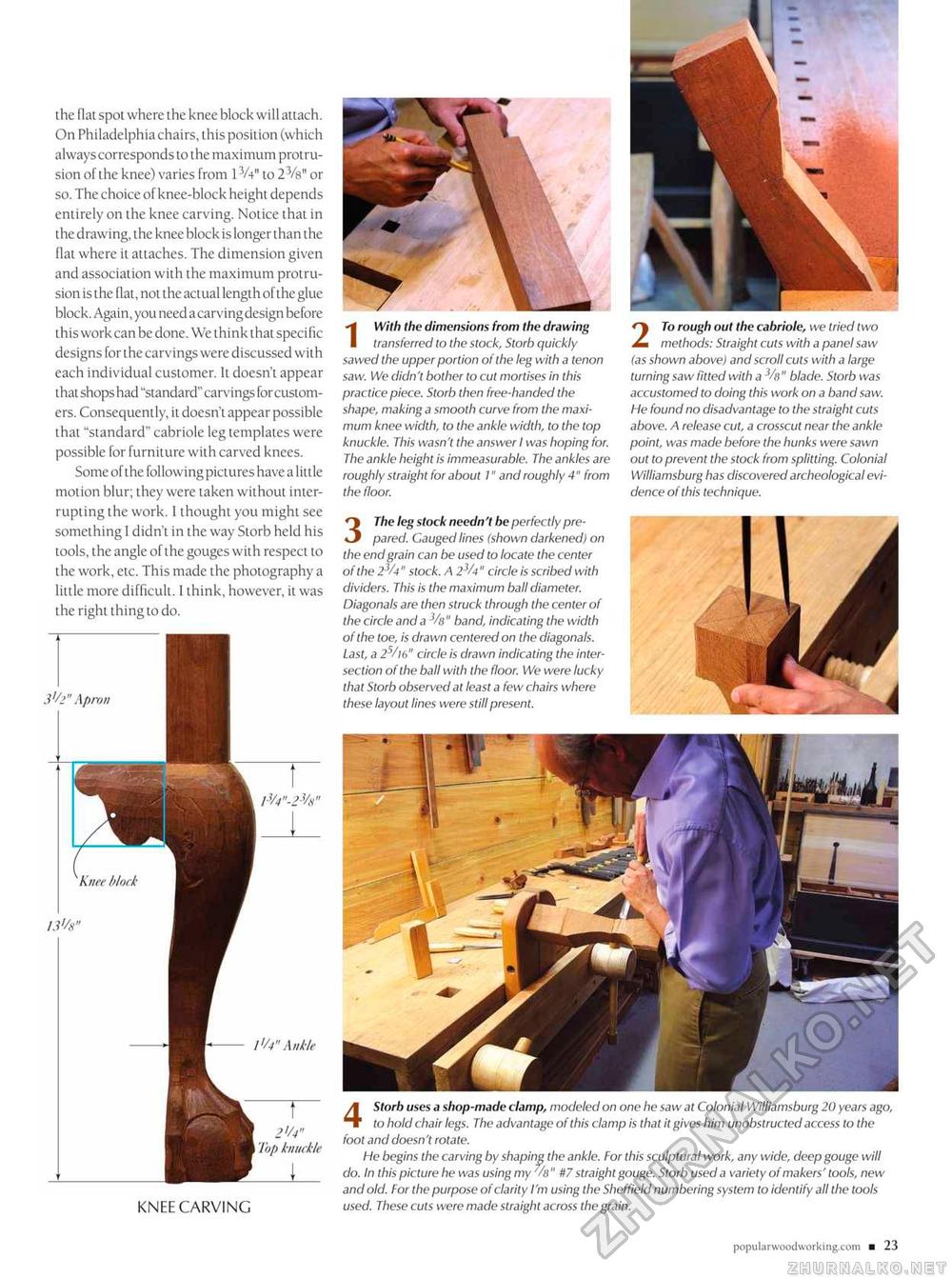

the flat spot where the knee block will attach. On Philadelphia chairs, this position (which always corresponds to the maximum protrusion of the knee) varies from l3An to 23/s" or so. The choice of knee-block height depends entirely on the knee carving. Notice that in the drawing, the knee block is longer than the flat where it attaches. The dimension given and association with the maximum protrusion is the flat, not the actual length of the glue block. Again, you need a carv ing design be fore this work can be done. We think that specific designs for the carvings were discussed with each individual customer. It doesn't appear that shops had "standard" carvings for customers. Consequently, it doesn't appear possible that "standard" cabriole leg templates were possible for furniture with carved knees. Some of the following pictures have a little motion blur; they were taken without interrupting the work. I thought you might see something I didn't in the way Storb held his tools, the angle of the gouges with respect to the work, etc. This made the photography a little more difficult. 1 think, however, it was the right thing to do. IWilh the dimensions from the drawing transferred to the stock, Storb quickly sawed the upper portion of the leg with a tenon saw. We didn't bother to cut mortises in this practice piece. Storb then free-handed the shape, making a smooth curve from the maximum knee width, to the ankle width, to the top knuckle. This wasn't the answer I was hoping for. The ankle height is immeasurable. The ankles are roughly straight for about I" and roughly 4" from the floor. 3 The leg stock needn't be perfectly prepared. Gauged lines (shown darkened) on the end grain can be used to locate the center of the 2/4" stock. A 23/4" circle is scribed with dividers. This is the maximum ball diameter. Diagonals are then struck through the center of the circle and a %" band, indicating the width of the toe, is drawn centered on the diagonals. Last, a 25/i6" circle is drawn indicating the intersection of the ball with the floor. We were lucky that Storb observed at least a few chairs where these layout lines were still present. 2 To rough out the cabriole, we tried two methods: Straight cuts with a panel saw (as shown above) and scroll cuts with a large turning saw fitted with a 3/s" blade. Storb was accustomed to doing this work on a band saw. He found no disadvantage to the straight cuts above. A release cut, a crosscut near the ankle point, was made before the hunks were sawn out to prevent the stock from splitting. Colonial Williamsburg has discovered archeological evidence of this technique. KNEE CARVING 4 Storb uses a shop-made clamp, modeled on one he saw at Colonial Williamsburg 20 years ago, to hold chair legs. The advantage of this clamp is that it gives him unobstructed access to the foot and doesn't rotate. He begins the carving by shaping the ankle. For this sculptural work, any wide, deep gouge will do. In this picture he was using my fa" If 7 straight gouge. Storb useda variety of makers' tools, new and old. For the purpose of clarity I'm using the Sheffield numbering system to identify all the tools used. These cuts were made straight across the grain. 1 23 |