Popular Woodworking 2009-04 № 175, страница 52

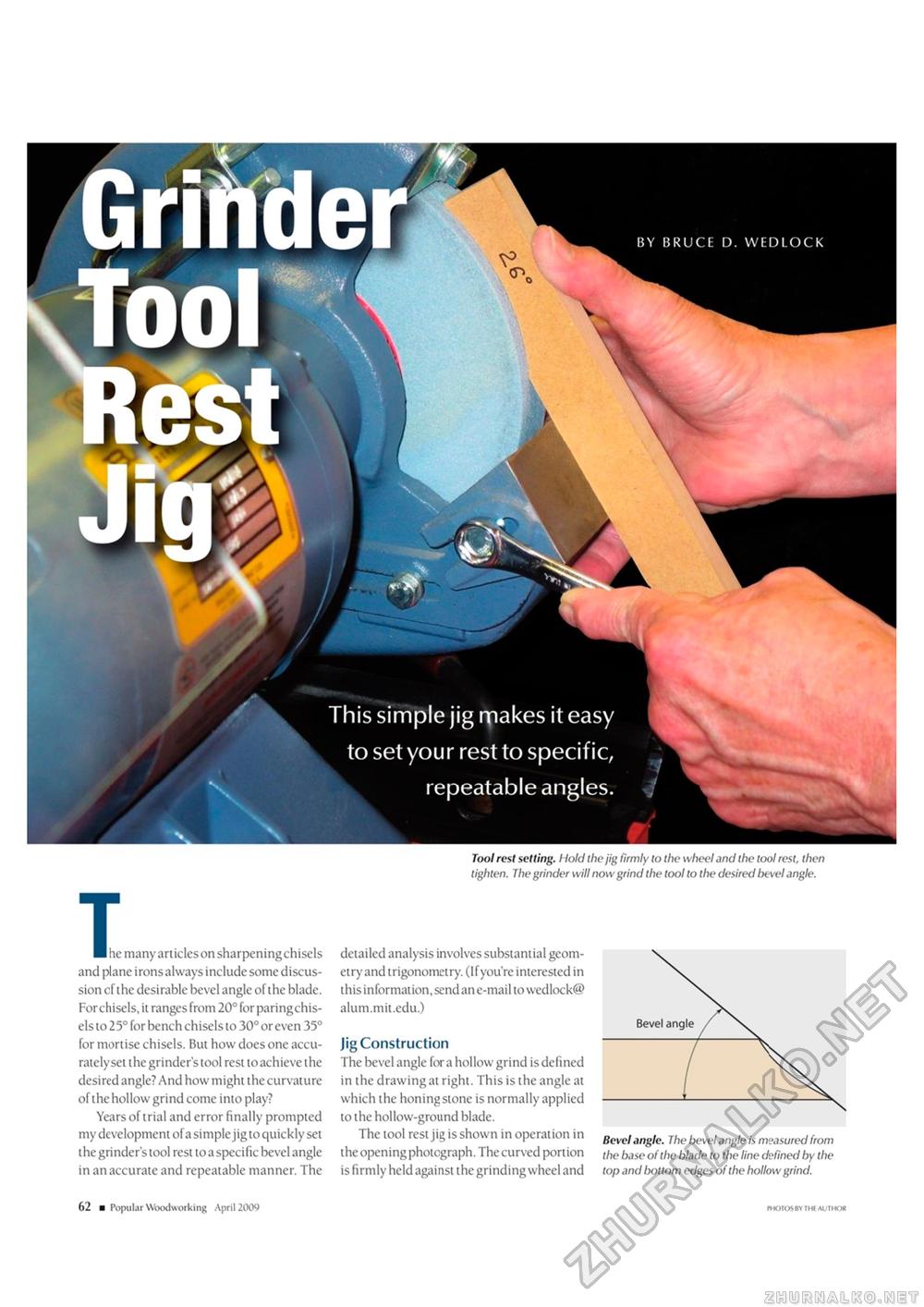

BY BRUCE D. WEDLOCK This simple jig makes it easy to set you r rest to specific, repeatable angles. ^Mhc Tool rest setting. I fold the jig firmly to the wheel and the tool rest, then tighten. The grinder will now grind the tool to the desired bevel angle. I he many articles on sharpening chisels and plane irons always include some discussion cfthe desirable bevel angle ofthe blade. For chisels, it ranges from 20°forparingchis-els to 25° for bench chisels to 30° or even 35° for mortise chisels. But how does one accurately set the grinder's tool rest to achieve the desired angle? And how might the curvature ofthe hollow grind come into play? Years of trial and error finally prompted my development of a simple jig to quickly set the grinder's tool rest to a specific bevel angle in an accurate and repeatable manner. The detailed analysis involves substantial geometry and trigonometry. (If you're interested in this information, send an e-mail to wedlock® alum.mit.edu.) Jig Construction The bevel angle for a hollow grind is defined in the drawing at right. This is the angle at which the honing stone is normally applied to the hollow-ground blade. The tool rest jig is shown in operation in the opening photograph. The curved portion is firmly held against the grinding wheel and Bevel angle. The bevel angle is measured from the base of the blade to the line defined by the top and bottom edges of the hollow grind. 62 ■ Popular Woodworking April 2009 fHOTOSBV THE AUTHOR |