Popular Woodworking 2009-10 № 178, страница 32

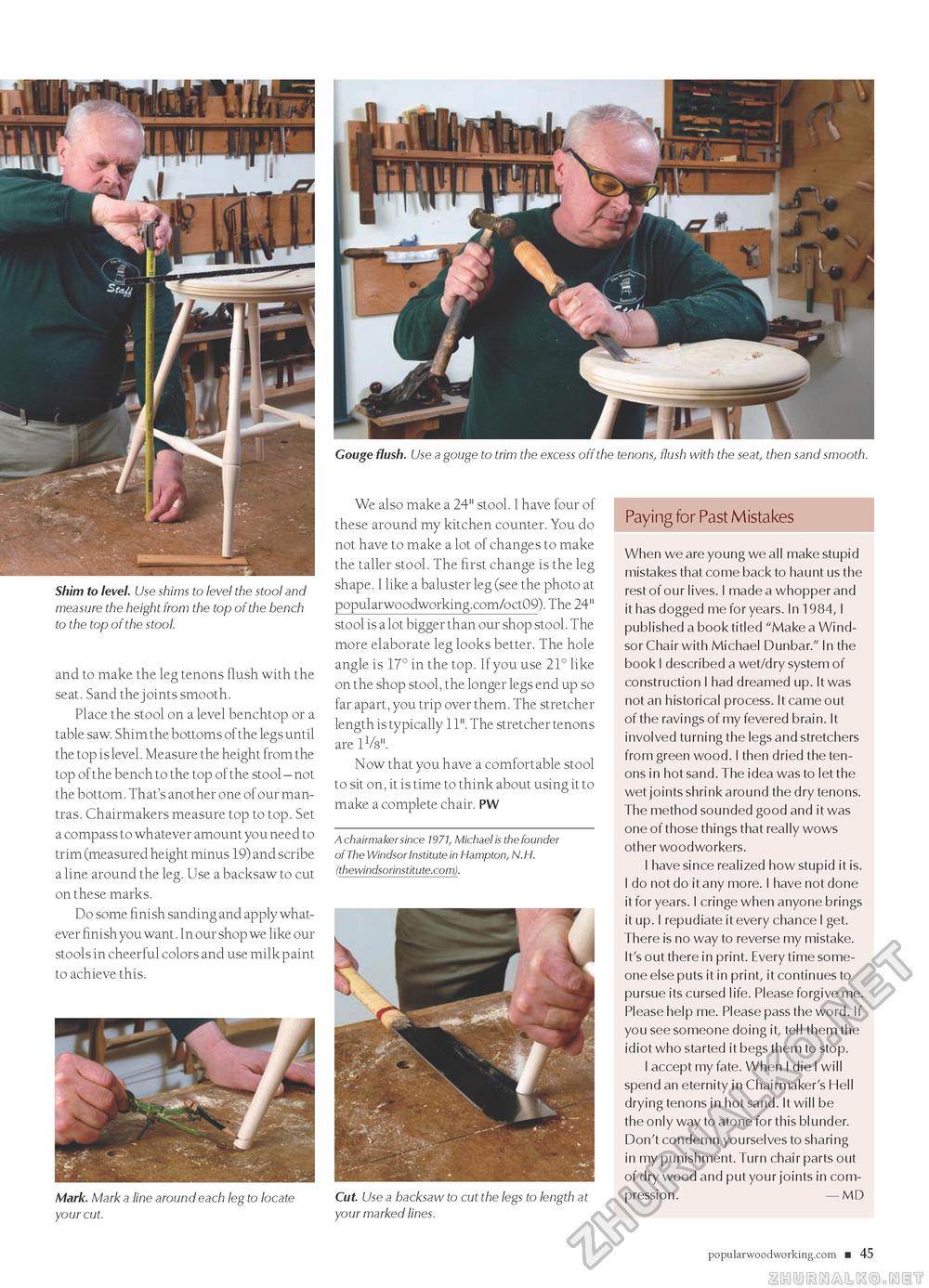

Shim to level. Use shims to level the stool and measure the height from the top of the bench to the top of the stool. and to make the leg tenons flush with the seat. Sand the joints smooth. Place the stool on a level benchtop or a table saw. Shim the bottoms of the legs until the top is level. Measure the height from the top of the bench to the top of the stool - not the bottom. That's another one of our mantras. Chairmakers measure top to top. Set a compass to whatever amount you need to trim (measured height minus 19) and scribe a line around the leg. Use a backsaw to cut on these marks. Do some finish sanding and apply whatever finish you want. In our shop we like our stools in cheerful colors and use milk paint to achieve this. Mark. Mark a line around each leg to locate your cut. Gouge flush. Use a gouge to trim the excess off the tenons, flush with the seat, then sand smooth. We also make a 24" stool. I have four of these around my kitchen counter. You do not have to make a lot of changes to make the taller stool. The first change is the leg shape. I like a baluster leg (see the photo at popularwoodworking.com/oct09). The 24" stool is a lot bigger than our shop stool. The more elaborate leg looks better. The hole angle is 17° in the top. If you use 21° like on the shop stool, the longer legs end up so far apart, you trip over them. The stretcher length is typically 11". The stretcher tenons are 1V8". Now that you have a comfortable stool to sit on, it is time to think about using it to make a complete chair. PW A chairmaker since 1971, Michael is the founder of The Windsor Institute in Hampton, N. H. (thewindsorinstitute.com). Cut. Use a backsaw to cut the legs to length at your marked lines. Paying for Past Mistakes When we are young we all make stupid mistakes that come back to haunt us the rest of our lives. i made a whopper and it has dogged me for years. in 1984, I published a book titled "Make a Windsor Chair with Michael Dunbar." In the book I described a wet/dry system of construction I had dreamed up. It was not an historical process. It came out of the ravings of my fevered brain. It involved turning the legs and stretchers from green wood. I then dried the tenons in hot sand. The idea was to let the wet joints shrink around the dry tenons. The method sounded good and it was one of those things that really wows other woodworkers. I have since realized how stupid it is. I do not do it any more. I have not done it for years. I cringe when anyone brings it up. I repudiate it every chance I get. There is no way to reverse my mistake. It's out there in print. Every time someone else puts it in print, it continues to pursue its cursed life. Please forgive me. Please help me. Please pass the word. If you see someone doing it, tell them the idiot who started it begs them to stop. I accept my fate. When I die I will spend an eternity in Chairmaker's Hell drying tenons in hot sand. It will be the only way to atone for this blunder. Don't condemn yourselves to sharing in my punishment. Turn chair parts out of dry wood and put your joints in compression. — MD popularwoodworking.com ■ 45 |