Popular Woodworking 2009-11 № 179, страница 37

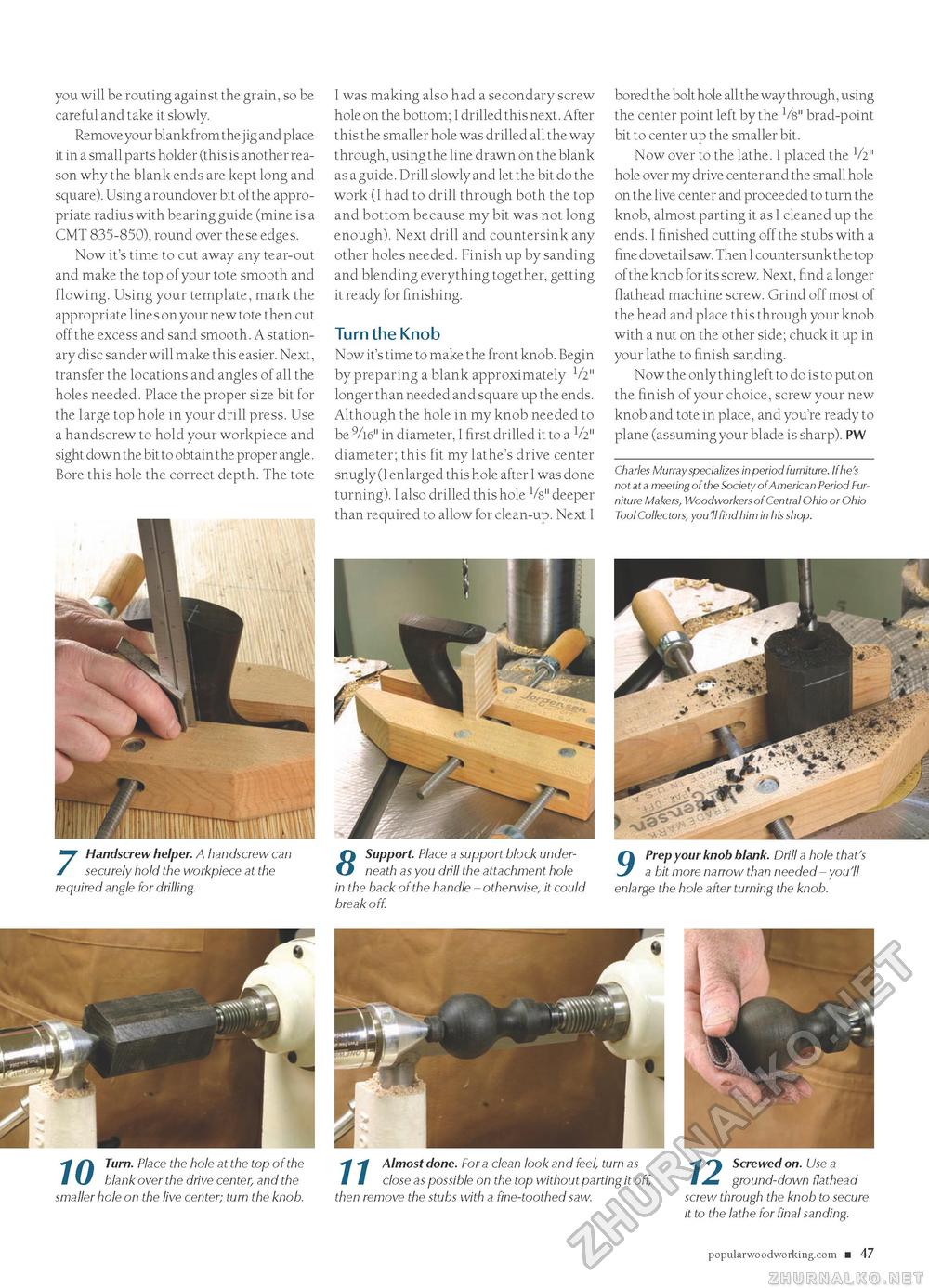

you will be routing against the grain, so be careful and take it slowly. Remove your blank from the jig and place it in a small parts holder (this is another reason why the blank ends are kept long and square). Using a roundover bit of the appropriate radius with bearing guide (mine is a CMT 835-850), round over these edges. Now it's time to cut away any tear-out and make the top of your tote smooth and flowing. Using your template, mark the appropriate lines on your new tote then cut off the excess and sand smooth. A stationary disc sander will make this easier. Next, transfer the locations and angles of all the holes needed. Place the proper size bit for the large top hole in your drill press. Use a handscrew to hold your workpiece and sight down the bit to obtain the proper angle. Bore this hole the correct depth. The tote I was making also had a secondary screw hole on the bottom; I drilled this next. After this the smaller hole was drilled all the way through, using the line drawn on the blank as a guide. Drill slowly and let the bit do the work (I had to drill through both the top and bottom because my bit was not long enough). Next drill and countersink any other holes needed. Finish up by sanding and blending everything together, getting it ready for finishing. Turn the Knob Now it's time to make the front knob. Begin by preparing a blank approximately 1/2" longer than needed and square up the ends. Although the hole in my knob needed to be 9/l6" in diameter, I first drilled it to a V2" diameter; this fit my lathe's drive center snugly (I enlarged this hole after I was done turning). I also drilled this hole V8" deeper than required to allow for clean-up. Next I bored the bolt hole all the way through, using the center point left by the 1/8" brad-point bit to center up the smaller bit. Now over to the lathe. I placed the 1/2" hole over my drive center and the small hole on the live center and proceeded to turn the knob, almost parting it as I cleaned up the ends. I finished cutting off the stubs with a fine dovetail saw. Then I countersunk the top of the knob for its screw. Next, find a longer flathead machine screw. Grind off most of the head and place this through your knob with a nut on the other side; chuck it up in your lathe to finish sanding. Now the only thing left to do is to put on the finish of your choice, screw your new knob and tote in place, and you're ready to plane (assuming your blade is sharp). PW Charles Murray specializes in period furniture. If he's not at a meeting of the Society of American Period Furniture Makers, Woodworkers of Central Ohio or Ohio Tool Collectors, you'll find him in his shop. 7 Handscrew helper. A handscrew can securely hold the workpiece at the required angle for drilling. 8 Support. Place a support block underneath as you drill the attachment hole in the back of the handle - otherwise, it could break off. 9 Prep your knob blank. Drill a hole that's a bit more narrow than needed - you'll enlarge the hole after turning the knob. 10 Turn. Place the hole at the top of the blank over the drive center, and the smaller hole on the live center; turn the knob. 11 Almost done. For a clean look and feel, turn as close as possible on the top without parting it off, then remove the stubs with a fine-toothed saw. <y Screwed on. Use a I ^ ground-down flathead screw through the knob to secure it to the lathe for final sanding. popularwoodworking.com ■ 47 |