Popular Woodworking 2009-11 № 179, страница 39

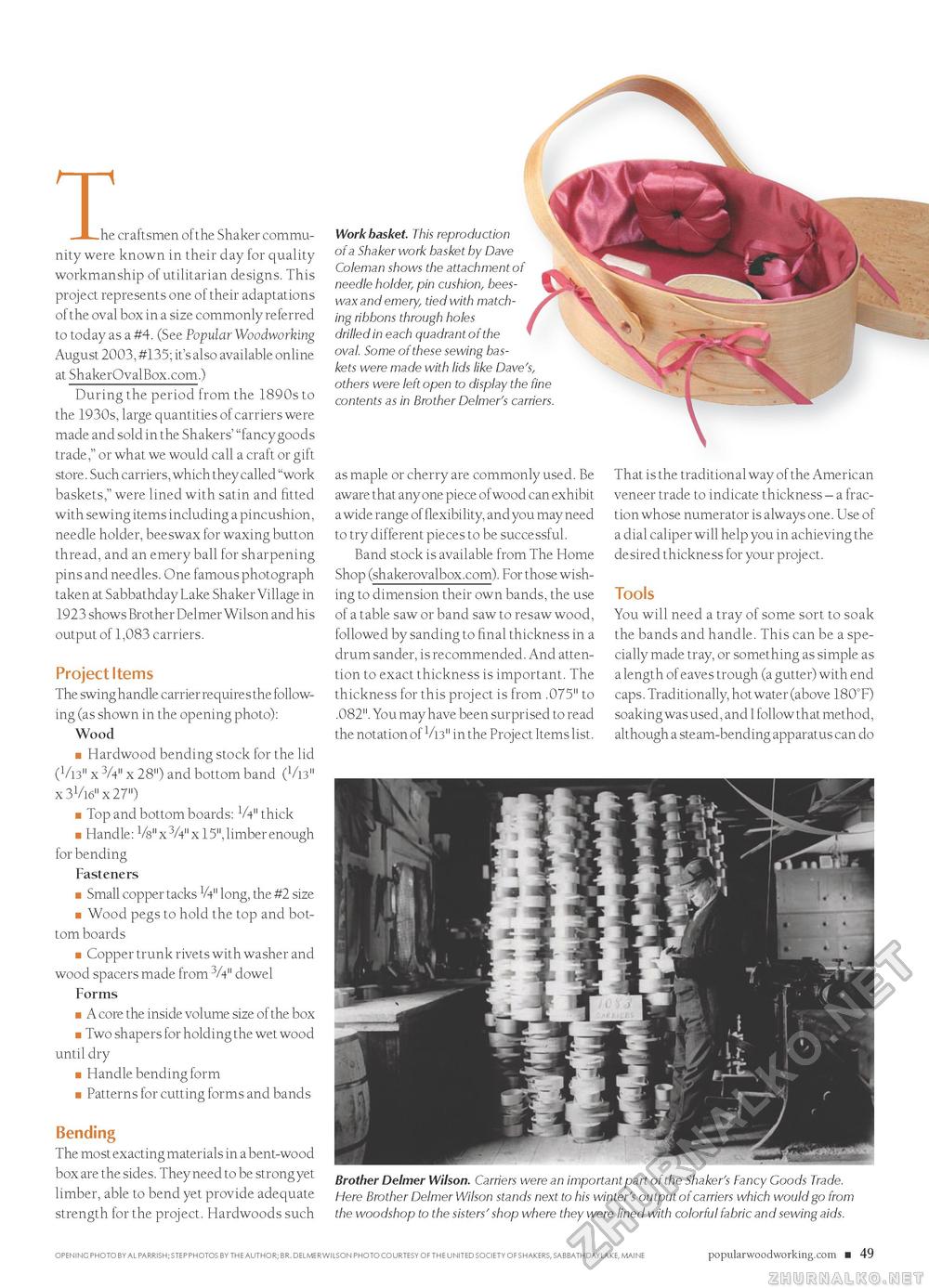

T1 he craftsmen of the Shaker community were known in their day for quality workmanship of utilitarian designs. This project represents one of their adaptations of the oval box in a size commonly referred to today as a #4. (See Popular Woodworking August 2003, #135; it's also available online at ShakerOvalBox.com.) During the period from the 1890s to the 1930s, large quantities of carriers were made and sold in the Shakers' "fancy goods trade," or what we would call a craft or gift store. Such carriers, which they called "work baskets," were lined with satin and fitted with sewing items including a pincushion, needle holder, beeswax for waxing button thread, and an emery ball for sharpening pins and needles. One famous photograph taken at Sabbathday Lake Shaker Village in 1923 shows Brother Delmer Wilson and his output of 1,083 carriers. Project Items The swing handle carrier requires the following (as shown in the opening photo): Wood ■ Hardwood bending stock for the lid (V13" x 3A" x 28") and bottom band (1/t3M x 3V16" x 27") ■ Top and bottom boards: V4" thick ■ Handle: Vs" x 3A" x15", limber enough for bending Fasteners ■ Small copper tacks V4" long, the #2 size ■ Wood pegs to hold the top and bottom boards ■ Copper trunk rivets with washer and wood spacers made from 3A" dowel Forms ■ A core the inside volume size of the box ■ Two shapers for holding the wet wood until dry ■ Handle bending form ■ Patterns for cutting forms and bands Bending The most exacting materials in a bent-wood box are the sides. They need to be strong yet limber, able to bend yet provide adequate strength for the project. Hardwoods such Work basket. This reproduction of a Shaker work basket by Dave Coleman shows the attachment of needle holder, pin cushion, beeswax and emery, tied with matching ribbons through holes drilled in each quadrant of the oval. Some of these sewing baskets were made with lids like Dave's, others were left open to display the fine contents as in Brother Delmer's carriers. as maple or cherry are commonly used. Be aware that any one piece of wood can exhibit a wide range of flexibility, and you may need to try different pieces to be successful. Band stock is available from The Home Shop (shakerovalbox.com). For those wishing to dimension their own bands, the use of a table saw or band saw to resaw wood, followed by sanding to final thickness in a drum sander, is recommended. And attention to exact thickness is important. The thickness for this project is from .075" to .082". You may have been surprised to read the notation of V13" in the Project Items list. That is the traditional way of the American veneer trade to indicate thickness - a fraction whose numerator is always one. Use of a dial caliper will help you in achieving the desired thickness for your project. Tools You will need a tray of some sort to soak the bands and handle. This can be a specially made tray, or something as simple as a length of eaves trough (a gutter) with end caps. Traditionally, hot water (above 180°F) soaking was used, and I follow that method, although a steam-bending apparatus can do Brother Delmer Wilson. Carriers were an important part of the Shaker's Fancy Goods Trade. Here Brother Delmer Wilson stands next to his winter's output of carriers which would go from the woodshop to the sisters' shop where they were lined with colorful fabric and sewing aids. OPENING PHOTO BY AL PARRISH; STEP PHOTOS BY THE AUTHOR; BR. DELMER WILSON PHOTO COURTESY OF THE UNITED SOCIETY OF SHAKERS, SABBATHDAYLAKE, MAINE popularwoodworking.com ■ 49 |