Popular Woodworking 2009-11 № 179, страница 41

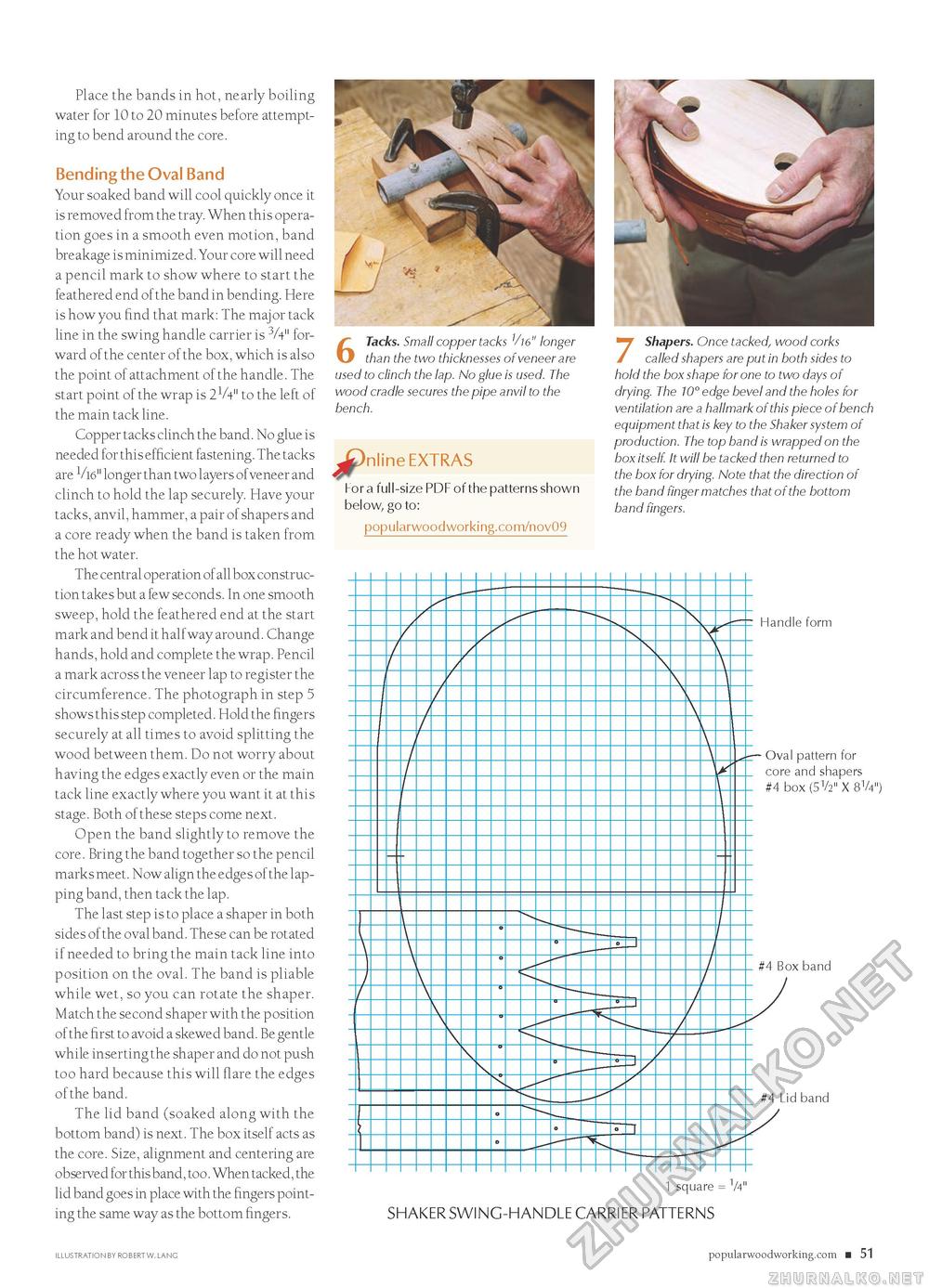

Place the bands in hot, nearly boiling water for 10 to 20 minutes before attempting to bend around the core. Bending the Oval Band Your soaked band will cool quickly once it is removed from the tray. When this operation goes in a smooth even motion, band breakage is minimized. Your core will need a pencil mark to show where to start the feathered end of the band in bending. Here is how you find that mark: The major tack line in the swing handle carrier is 3A" forward of the center of the box, which is also the point of attachment of the handle. The start point of the wrap is 2V4" to the left of the main tack line. Copper tacks clinch the band. No glue is needed for this efficient fastening. The tacks are 1/16" longer than two layers ofveneer and clinch to hold the lap securely. Have your tacks, anvil, hammer, a pair of shapers and a core ready when the band is taken from the hot water. The central operation of all box construction takes but a few seconds. In one smooth sweep, hold the feathered end at the start mark and bend it half way around. Change hands, hold and complete the wrap. Pencil a mark across the veneer lap to register the circumference. The photograph in step 5 shows this step completed. Hold the fingers securely at all times to avoid splitting the wood between them. Do not worry about having the edges exactly even or the main tack line exactly where you want it at this stage. Both of these steps come next. Open the band slightly to remove the core. Bring the band together so the pencil marks meet. Now align the edges of the lapping band, then tack the lap. The last step is to place a shaper in both sides of the oval band. These can be rotated if needed to bring the main tack line into position on the oval. The band is pliable while wet, so you can rotate the shaper. Match the second shaper with the position of the first to avoid a skewed band. Be gentle while inserting the shaper and do not push too hard because this will flare the edges of the band. The lid band (soaked along with the bottom band) is next. The box itself acts as the core. Size, alignment and centering are observed for this band, too. When tacked, the lid band goes in place with the fingers pointing the same way as the bottom fingers. illustration BY ROBERT w. Lang 6 Tacks. Small copper tacks Vl6" longer than the two thicknesses of veneer are used to clinch the lap. No glue is used. The wood cradle secures the pipe anvil to the bench. For a full-size PDF of the patterns shown below, go to: popularwoodworking.com/nov09 7 Shapers. Once tacked, wood corks called shapers are put in both sides to hold the box shape for one to two days of drying. The 10° edge bevel and the holes for ventilation are a hallmark of this piece of bench equipment that is key to the Shaker system of production. The top band is wrapped on the box itself. It will be tacked then returned to the box for drying. Note that the direction of the band finger matches that of the bottom band fingers. SHAKER SWING-HANDLE CARRIER PATTERNS popularwoodworking.com ■ 51 |