Popular Woodworking 2009-11 № 179, страница 7

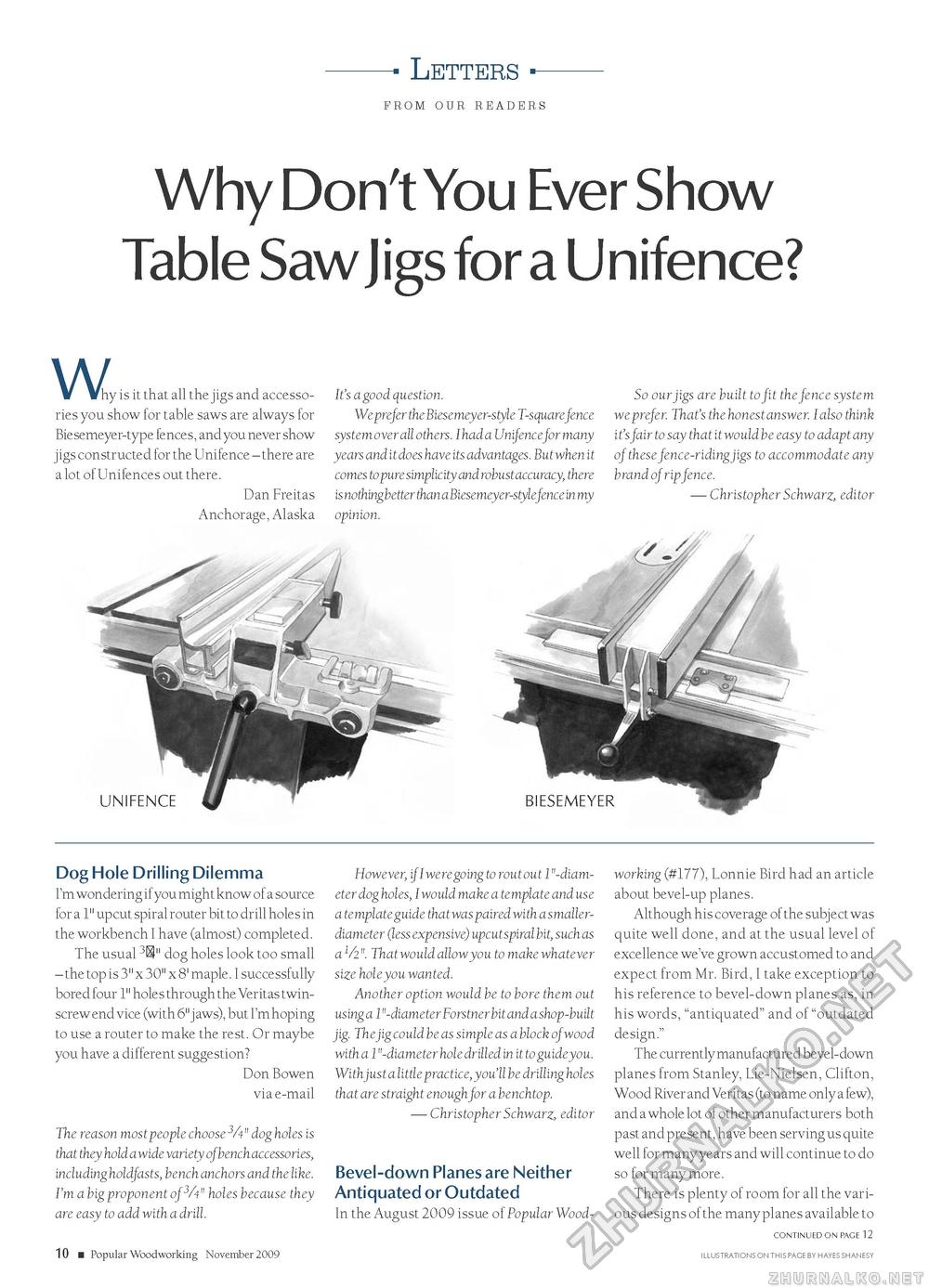

- Letters - FROM OUR READERS Why Don't You Ever Show Table Saw Jigs for a Unifence? W ' hy is it that all the jigs and accessories you show for table saws are always for Biesemeyer-type fences, and you never show jigs constructed for the Unifence - there are a lot of Unifences out there. Dan Freitas Anchorage, Alaska It's a good question. Weprefer the Biesemeyer-style T-squarefence system over all others. I had a Unifence for many years and it does have its advantages. But when it comes to pure simplicity and robust accuracy, there is nothing better than a Biesemeyer-style fence in my opinion. So our jigs are built to fit the fence system we prefer. That's the honest answer. I also think it's fair to say that it would be easy to adapt any of these fence-ridingjigs to accommodate any brand of rip fence. — ChristopherSchwarz, editor UNIFENCE BIESEMEYER Dog Hole Drilling Dilemma I'm wondering if you might know of a source for a 1"" upcut spiral router bit to drill holes in the workbench I have (almost) completed. The usual 3Z3" dog holes look too small - the top is 3" x 30" x 8' maple. I successfully bored four 1"" holes through the Veritas twin-screw end vice (with 6" jaws), but I'm hoping to use a router to make the rest. Or maybe you have a different suggestion? Don Bowen via e-mail The reason most people choose 3A" dog holes is that they hold a wide variety of bench accessories, including holdfasts, bench anchors and the like. I'm a big proponent of 3A" holes because they are easy to add with a drill. 10 ■ Popular Woodworking November 2009 However, if I were going to rout out 1 "-diameter dog holes, I would make a template and use a template guide that was paired with a smaller-diameter (less expensive) upcut spiral bit, such as a 1/2". That would allow you to make whatever size hole you wanted. Another option would be to bore them out using a 1 "-diameter Forstner bit and a shop-built jig The jig could be as simple as a block of wood with a 1 "-diameter hole drilled in it to guideyou. With just a little practice, you'll be drilling holes that are straight enough for a benchtop. — Christopher Schwarz, editor Bevel-down Planes are Neither Antiquated or Outdated In the August 2009 issue of Popular Wood working (#177), Lonnie Bird had an article about bevel-up planes. Although his coverage of the subject was quite well done, and at the usual level of excellence we've grown accustomed to and expect from Mr. Bird, I take exception to his reference to bevel-down planes as, in his words, "antiquated" and of "outdated design." The currently manufactured bevel-down planes from Stanley, Lie-Nielsen, Clifton, Wood River and Veritas (to name only a few), and a whole lot of other manufacturers both past and present, have been serving us quite well for many years and will continue to do so for many more. There is plenty of room for all the various designs of the many planes available to CONTiNUED ON PAGE 12 ILLUSTRATIONS ON THIS RACE BY HAYES SHANESY |