16 - Custonize Your Radial Arm Saw, страница 10

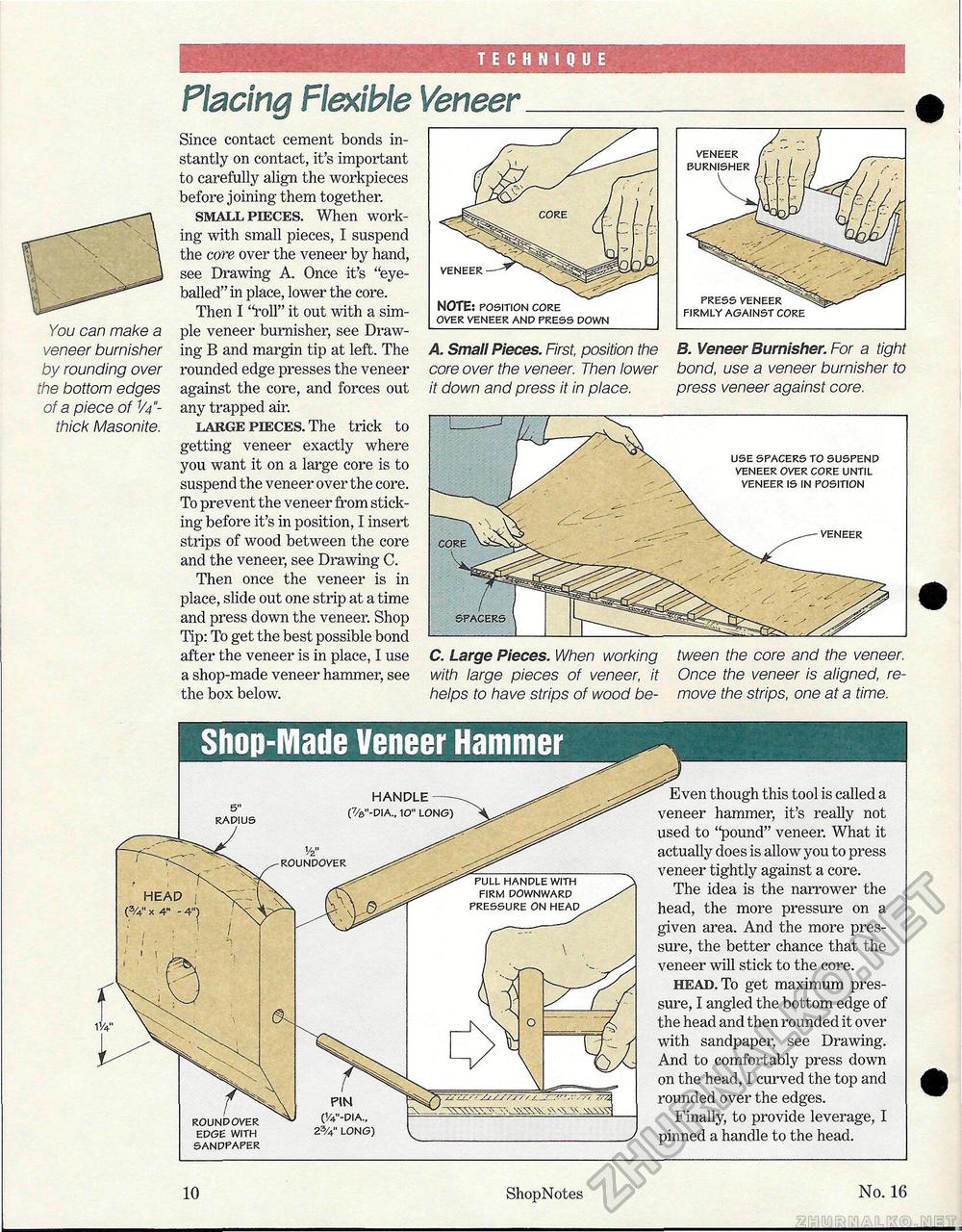

TECHNIQUE Placing Flexible Veneer You can make a veneer burnisher by rounding over the bottom edges of a piece of V4-thick Masonite. Since contact cement bonds instantly on contact, it's important to carefully align the workpieces before joining them together. small pieces. When working with small pieces, I suspend the core over the veneer by hand, see Drawing A. Once it's "eye-balled" in place, lower the core. Then I "roll" it out with a simple veneer burnisher, see Drawing B and margin tip at left. The rounded edge presses the veneer against the core, and forces out any trapped air. large pieces. The trick to getting veneer exactly where you want it on a large core is to suspend the veneer over the core. To prevent the veneer from sticking before it's in position, I insert strips of wood between the core and the veneer, see Drawing C. Then once the veneer is in place, slide out one strip at a time and press down the veneer. Shop Tip: To get the best possible bond after the veneer is in place, I use a shop-made veneer hammer, see the box below. veneer NOTE: position core over veneer and press down A. Small Pieces. First, position the core over the veneer. Then lower it down and press it in place. B. Veneer Burnisher. For a tight bond, use a veneer burnisher to press veneer against core. use spacers to suspend veneer over core until veneer is in position veneer C. Large Pieces. When working with large pieces of veneer, it helps to have strips of wood be tween the core and the veneer. Once the veneer is aligned, remove the strips, one at a time. veneer burnisher press veneer firmly against core roundover pull handle with firm downward pressure on head 3S5SSS Shop-Made Veneer HammerEven though this tool is called a veneer hammer, it's really not used to "pound" veneer. What it actually does is allow you to press veneer tightly against a core. The idea is the narrower the head, the more pressure on a given area. And the more pressure, the better chance that the veneer will stick to the core. head. To get maximum pressure, I angled the bottom edge of the head and then rounded it over with sandpaper, see Drawing. And to comfortably press down on the head, I curved the top and rounded over the edges. Finally, to provide leverage, I pinned a handle to the head. 5" radius HEAP (3/4" x 4" - 4" roundover edge with sandpaper HANDLE—- (7/6m-dia., 10" long) ts'v'7~7T/..'■' '/.'--T 77Z. "O^O-X WWAs \\\Vg 10 ShopNotes No. 16 |