36 - Miter Trimmer, страница 28

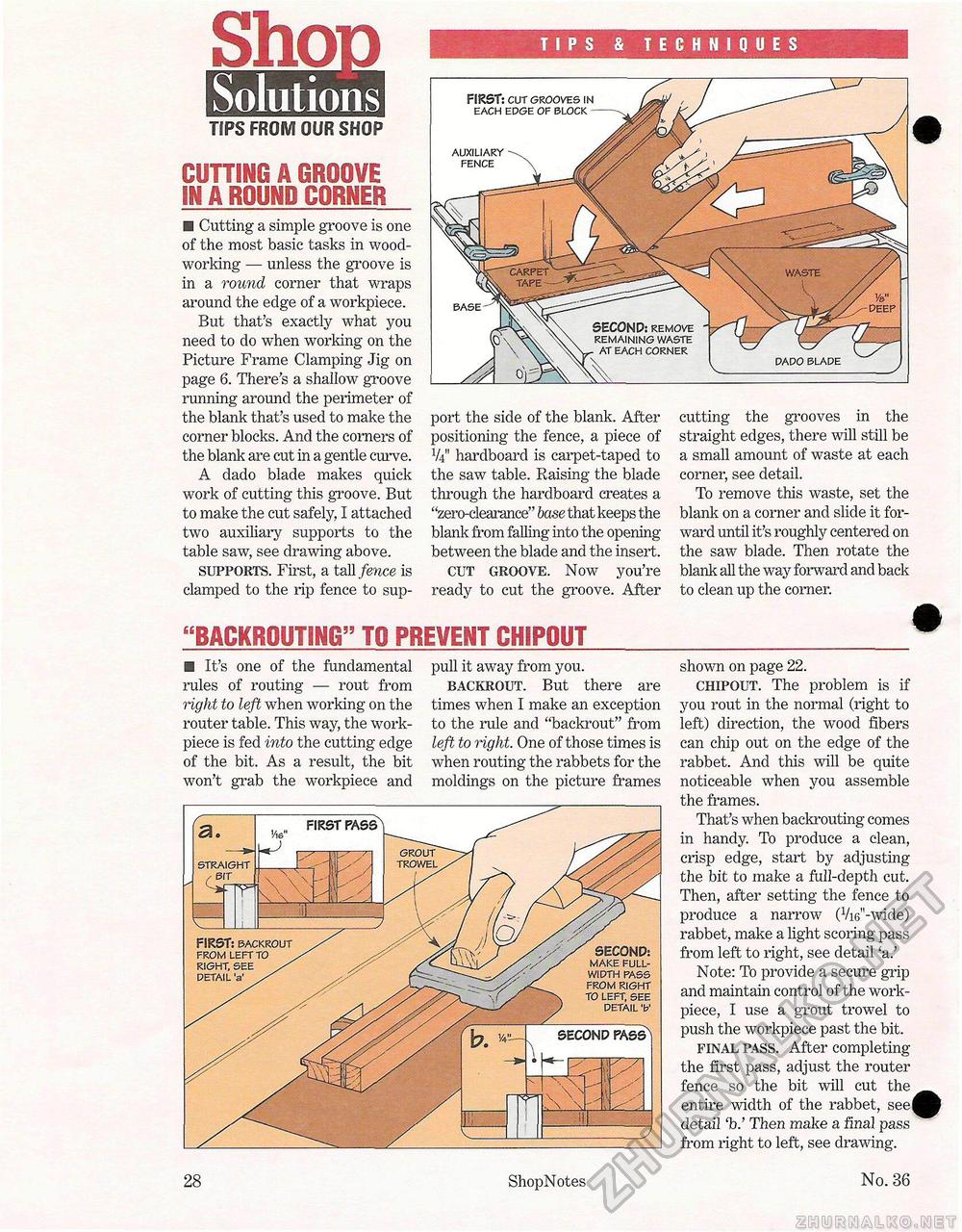

ShopSolutionsTIPS FROM OUR SHOP TIPS TECHNIQUES CUTTING A GROOVE IN A ROUND CORNER ■ Cutting a simple groove is one of the most basic tasks in woodworking — unless the groove is in a round corner that wraps around the edge of a workpiece. But that's exactly what you need to do when working on the Picture Frame Clamping Jig on page 6. There's a shallow groove running around the perimeter of the blank that's used to make the corner blocks. And the corners of the blank are cut in a gentle curve. A dado blade makes quick work of cutting this groove. But to make the cut safely, I attached two auxiliary supports to the table saw, see drawing above. supports. First, a tall fence is clamped to the rip fence to sup El It's one of the fundamental rules of routing — rout from right to left when working on the router table. This way, the work-piece is fed into the cutting edge of the bit. As a result, the bit won't grab the workpiece and 28 port the side of the blank. After positioning the fence, a piece of V4" hardboard is carpet-taped to the saw table. Raising the blade through the hardboard creates a "zero-clearance" base that keeps the blank from falling into the opening between the blade and the insert. cut groove. Now you're ready to cut the groove. After pull it away from you. backrout. But there are times when I make an exception to the rule and "backrout" from left to right. One of those times is when routing the rabbets for the moldings on the picture frames Shop Notes cutting the grooves in the straight edges, there 'will still be a small amount of waste at each corner, see detail. To remove this waste, set the blank on a corner and slide it forward until it's roughly centered on the saw blade. Then rotate the blank all the way forward and back to clean up the corner. shown on page 22. chipout. The problem is if you rout in the normal (right to left) direction, the wood fibers can chip out on the edge of the rabbet. And this will be quite noticeable when you assemble the frames. That's when backrouting comes in handy. To produce a clean, crisp edge, start by adjusting the bit to make a full-depth cut. Then, after setting the fence to produce a narrow (Vi6"-wide) rabbet, make a light scoring pass from left to right, see detail 'a.' Note: To provide a secure grip and maintain control of the work-piece, I use a grout trowel to push the workpiece past the bit. final pass. After completing the first pass, adjust the router fence so the bit will cut the entire width of the rabbet, seei detail 'b.' Then make a final pass from right to left, see drawing. No. 36 "BACKROUTING" TO PREVENT CHIPOUT base Vs" DEEP DADO BLADE FIRST: cut grooves in each edge OF block auxiliary FENCE STRAIGHT FIRST PASS FIRST: BACKROUT FROM LEFT TO RIGHT, SEE DETAIL 'a' SECOND: MAKE FULL-WIDTH PASS FROM RIGHT TO LEFT, SEE DETAIL V SECOND PASS |