40 - Vacuum Clamping System, страница 24

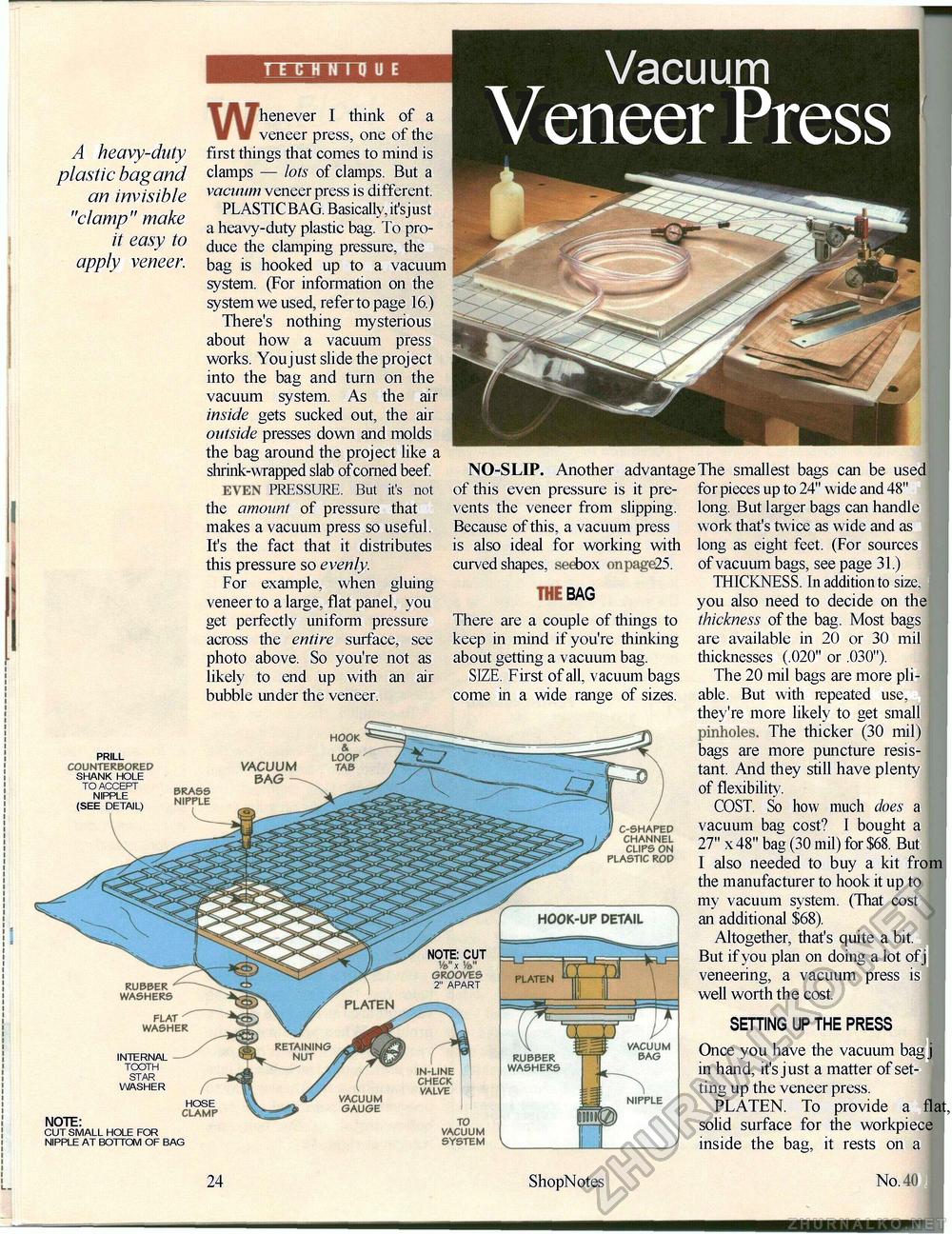

A heavy-duty plastic bag and an invisible "clamp" make it easy to apply veneer. Whenever I think of a veneer press, one of the first things that comes to mind is clamps — lots of clamps. But a vacuum veneer press is different. PLASTIC BAG. Basically, it'sjust a heavy-duty plastic bag. To produce the clamping pressure, the bag is hooked up to a vacuum system. (For information on the system we used, refer to page 16.) There's nothing mysterious about how a vacuum press works. You just slide the project into the bag and turn on the vacuum system. As the air inside gets sucked out, the air outside presses down and molds the bag around the project like a shrink-wrapped slab of corned beef. EVEN PRESSURE. But it's not the amount of pressure that makes a vacuum press so useful. It's the fact that it distributes this pressure so evenly. For example, when gluing veneer to a large, flat panel, you get perfectly uniform pressure across the entire surface, see photo above. So you're not as likely to end up with an air bubble under the veneer. Vacuum Veneer Press NO-SLIP. Another advantage The smallest bags can be used of this even pressure is it prevents the veneer from slipping. Because of this, a vacuum press is also ideal for working with curved shapes, seebox onpage25. THE BAG There are a couple of things to keep in mind if you're thinking about getting a vacuum bag. SIZE. First of all, vacuum bags come in a wide range of sizes. PRILL COUNTERBOREP SHANK HOLE TO ACCEPT NIPPLE (SEE DETAIL) INTERNAL TOOTH STAR WASHER HOSE CLAMP note: CUT SMALL HOLE FOR NIPPLE AT BOTTOM OF BAG 24 ShopNotes for pieces up to 24" wide and 48" long. But larger bags can handle work that's twice as wide and as long as eight feet. (For sources of vacuum bags, see page 31.) THICKNESS. In addition to size, you also need to decide on the thickness of the bag. Most bags are available in 20 or 30 mil thicknesses (.020" or .030"). The 20 mil bags are more pliable. But with repeated use, they're more likely to get small pinholes. The thicker (30 mil) bags are more puncture resistant. And they still have plenty of flexibility. COST. So how much does a vacuum bag cost? I bought a 27" x 48" bag (30 mil) for $68. But I also needed to buy a kit from the manufacturer to hook it up to my vacuum system. (That cost an additional $68). Altogether, that's quite a bit. But if you plan on doing a lot of j veneering, a vacuum press is well worth the cost. SETTING UP THE PRESS Once you have the vacuum bag j in hand, it's just a matter of setting up the veneer press. PLATEN. To provide a flat, solid surface for the workpiece inside the bag, it rests on a No. |